A magnesium ingot processing unit

A unit and magnesium ingot technology, which is applied in the field of magnesium ingot processing equipment and magnesium ingot processing unit, can solve the problems of increasing equipment investment cost, wasting electric energy, and scrapping cutter rollers, etc., and achieves reducing equipment investment cost, production cost, and motor reduction. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

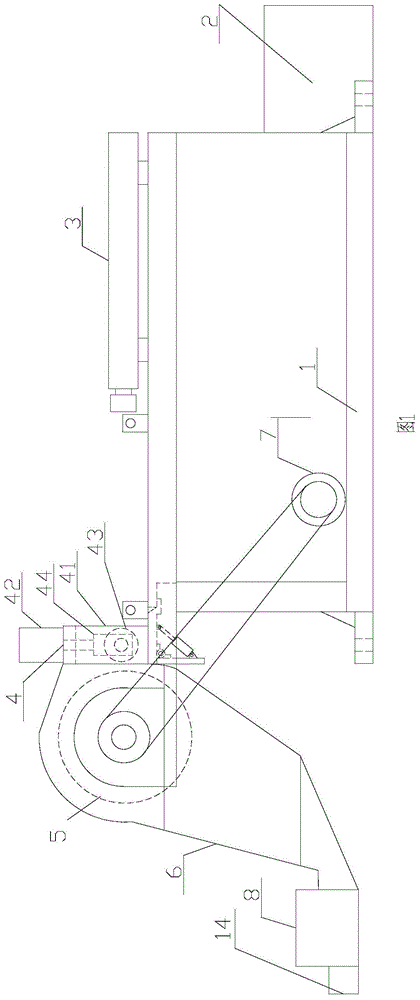

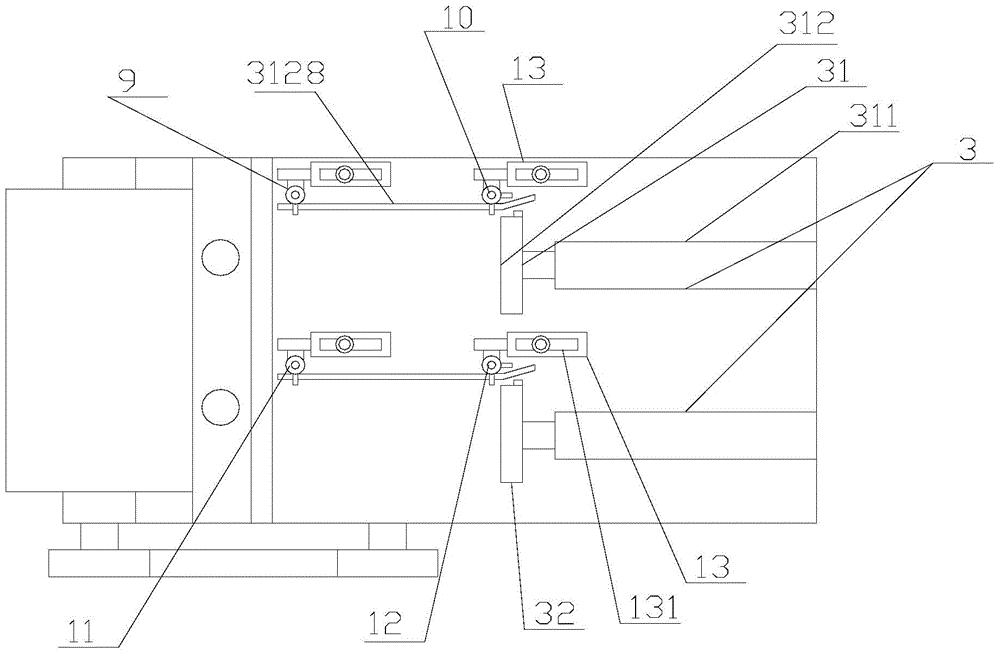

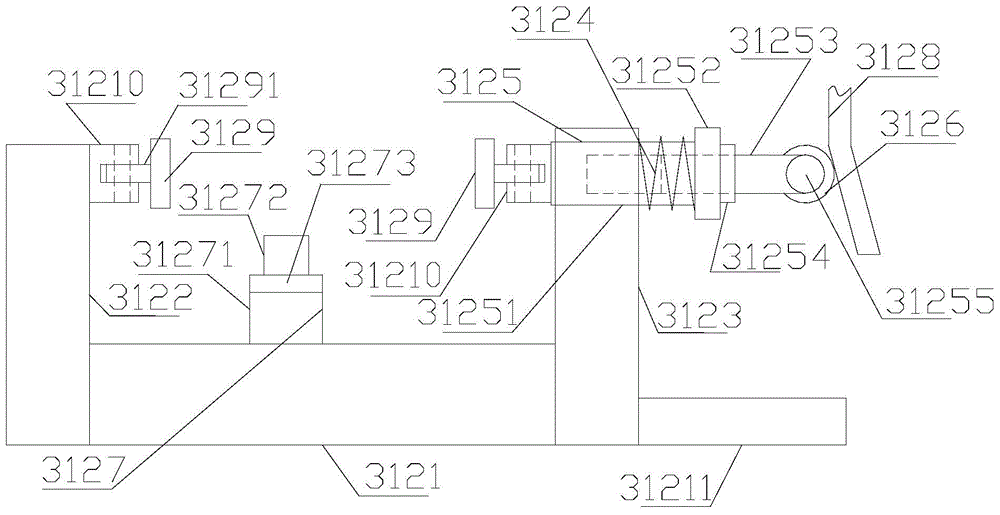

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a magnesium ingot processing unit of the present invention, comprising a frame body 1, a hydraulic station 2, a pushing device 3, a pressing mechanism 4, a knife roller 5, a collecting hopper 6, a first motor 7, a chip breaker 8 and a fan 14, The front end of the frame body 1 is provided with a knife roller 5 and a collecting hopper 6, the collecting hopper 6 is arranged below the knife roller 5, the collecting hopper 6 is connected with the fan 14 through a chip breaker 8, and the knife roller 5 Connected with the first motor 7, the platform of the frame body 1 is provided with a pressing mechanism 4, the pressing mechanism 4 is close to the knife roller 5, and the rear part of the platform of the frame body 1 is provided with a pushing device 3 , the hydraulic station 2 is connected with the pushing device 3 and the pressing mechanism 4 through the oil pipe, and the pushing device 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com