Ultra-long hard alloy deep hole twist drill for deep hole processing

A hard alloy and twist drill technology, which is applied in twist drills, metal processing equipment, drilling/drilling equipment, etc., can solve the problem that the processing accuracy and efficiency cannot meet the requirements, the efficiency cannot meet the requirements, and the center cooling cannot be realized, etc. problems, to achieve the effect of not easy to chip, increase rigidity, and not easy to break the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

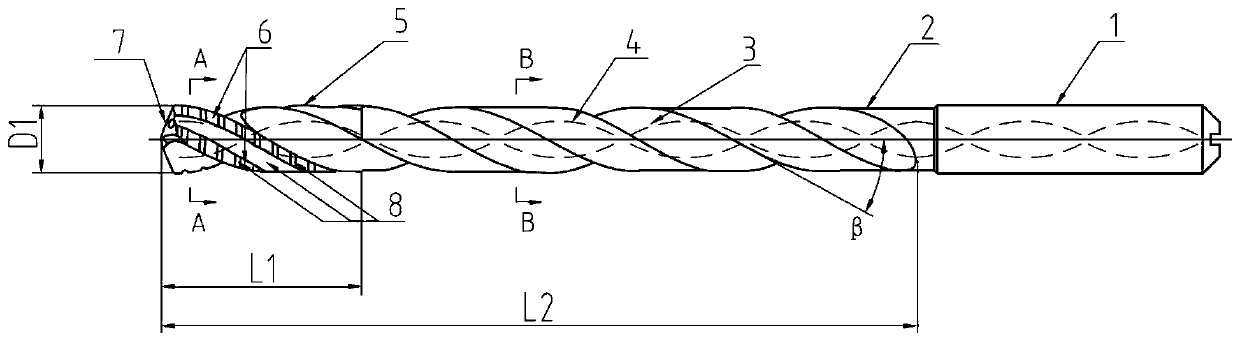

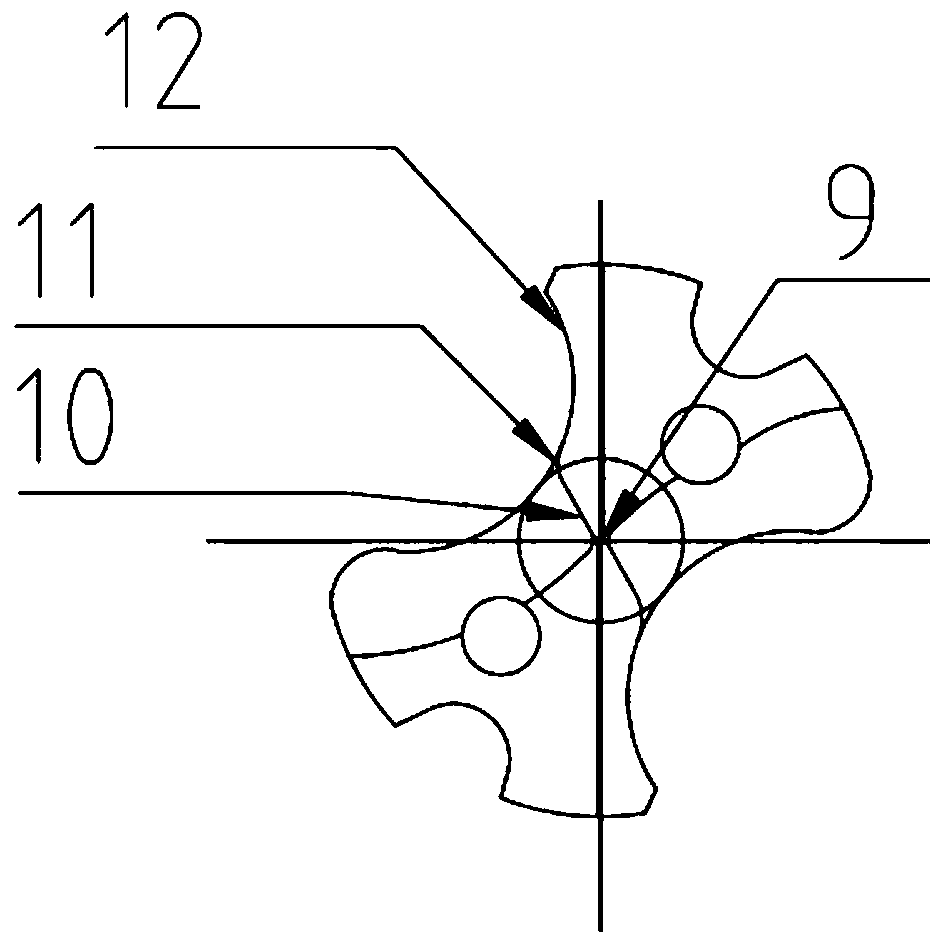

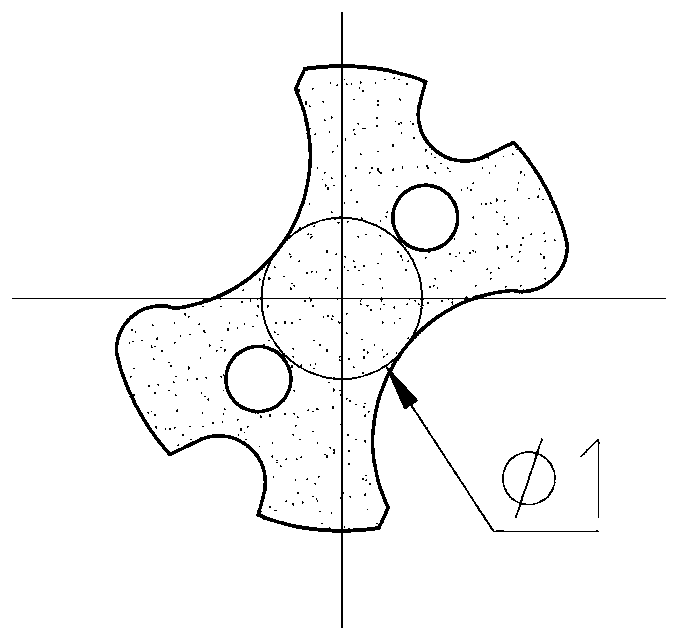

[0039] Such as Figure 1-7 As shown, an ultra-long hard alloy deep hole twist drill for deep hole processing includes a shank 1 and a blade 5, the central axis of the two is on the same straight line, and the shank 1 is used for installing the tool and the handle. There is a void 2 between the shank 1 and the blade 5 to reduce the friction of the hole wall. Two spiral chip removal flutes 3 are arranged on the blade 5 along the central axis, and two chip removal grooves 3 are used to form two The back 4, the back 4 is a necessary part of the drill structure, the shape and size of the back determine the drilling efficiency and the life of the drill, the blade 5 (left end) is provided with a mesh support surface 6, and the support surface 6 is the drilling guide , to improve the machining accuracy of the hole, a mesh U-shaped cooling groove 8 is provided on the supporting surface 6, and a plurality of U-shaped cooling grooves 8 cross to form a network structure in the form of a "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com