Combined forming cutter

A technology for cutting tools and jigs, which is applied to lathe tools, manufacturing tools, accessories of tool holders, etc. It can solve the problems that large-diameter workpieces and deep grooves cannot be cut, and only brittle materials can be cut. It is not easy to break the knife, has a wide range of uses, and has the effect of low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in detail as follows with reference to accompanying drawing:

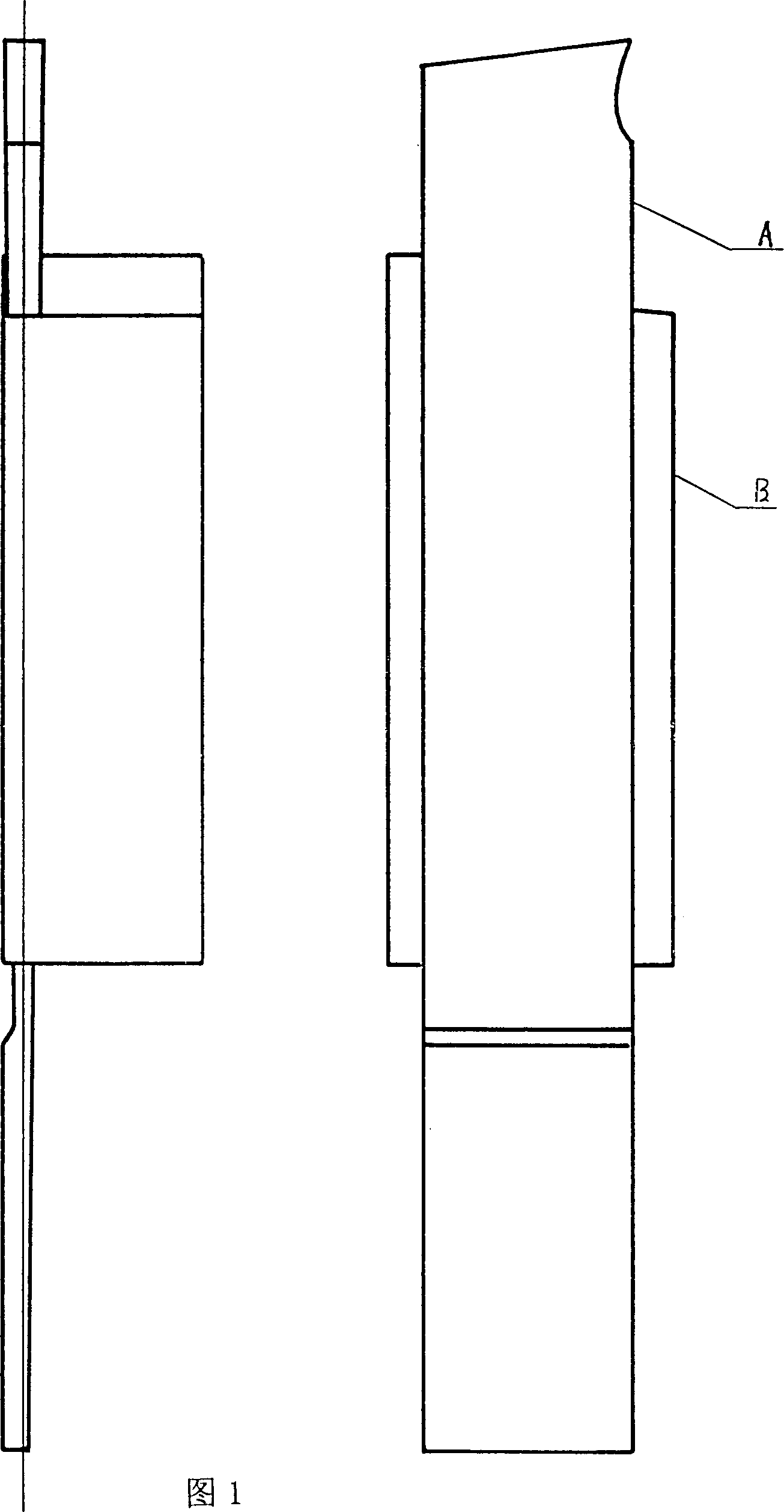

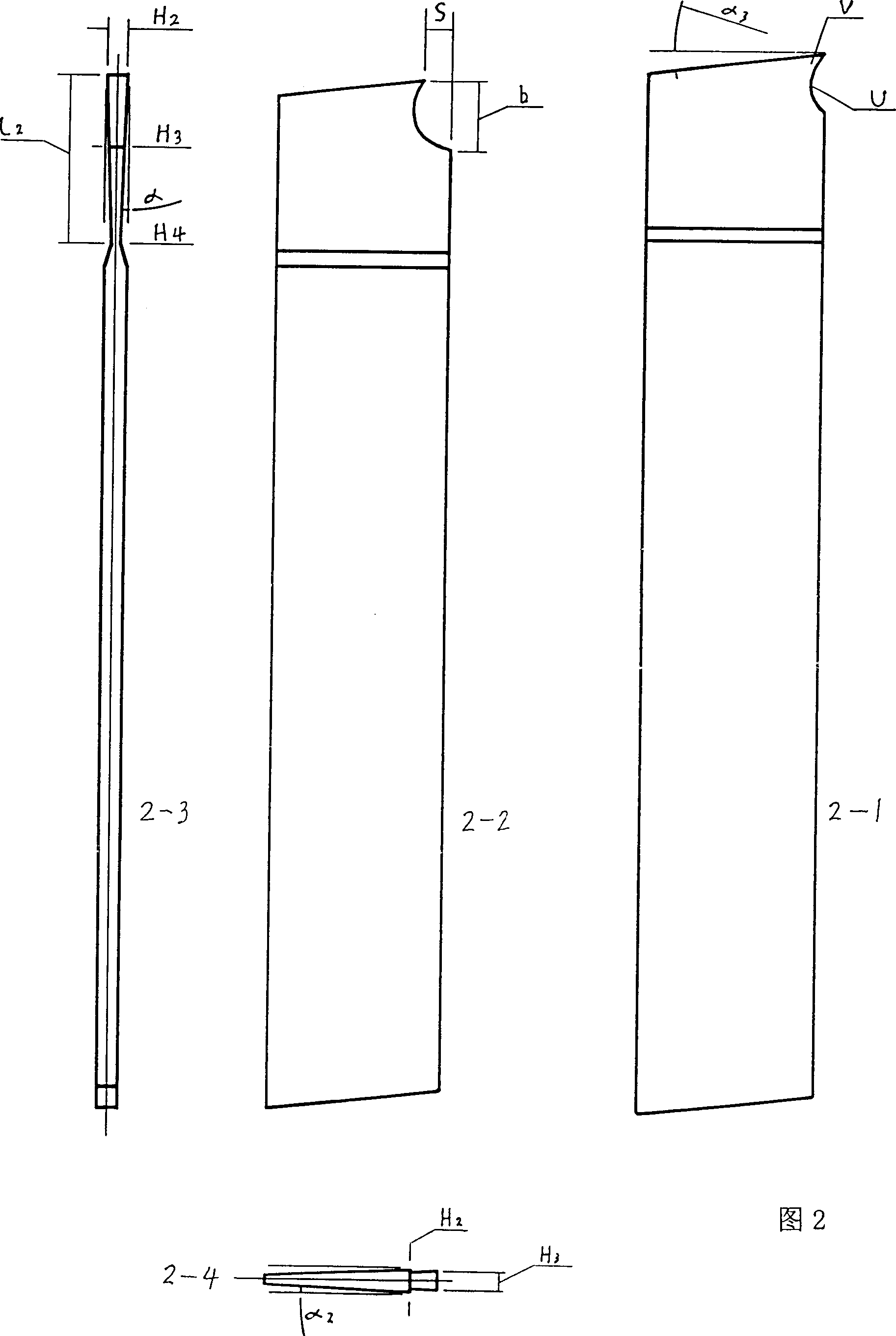

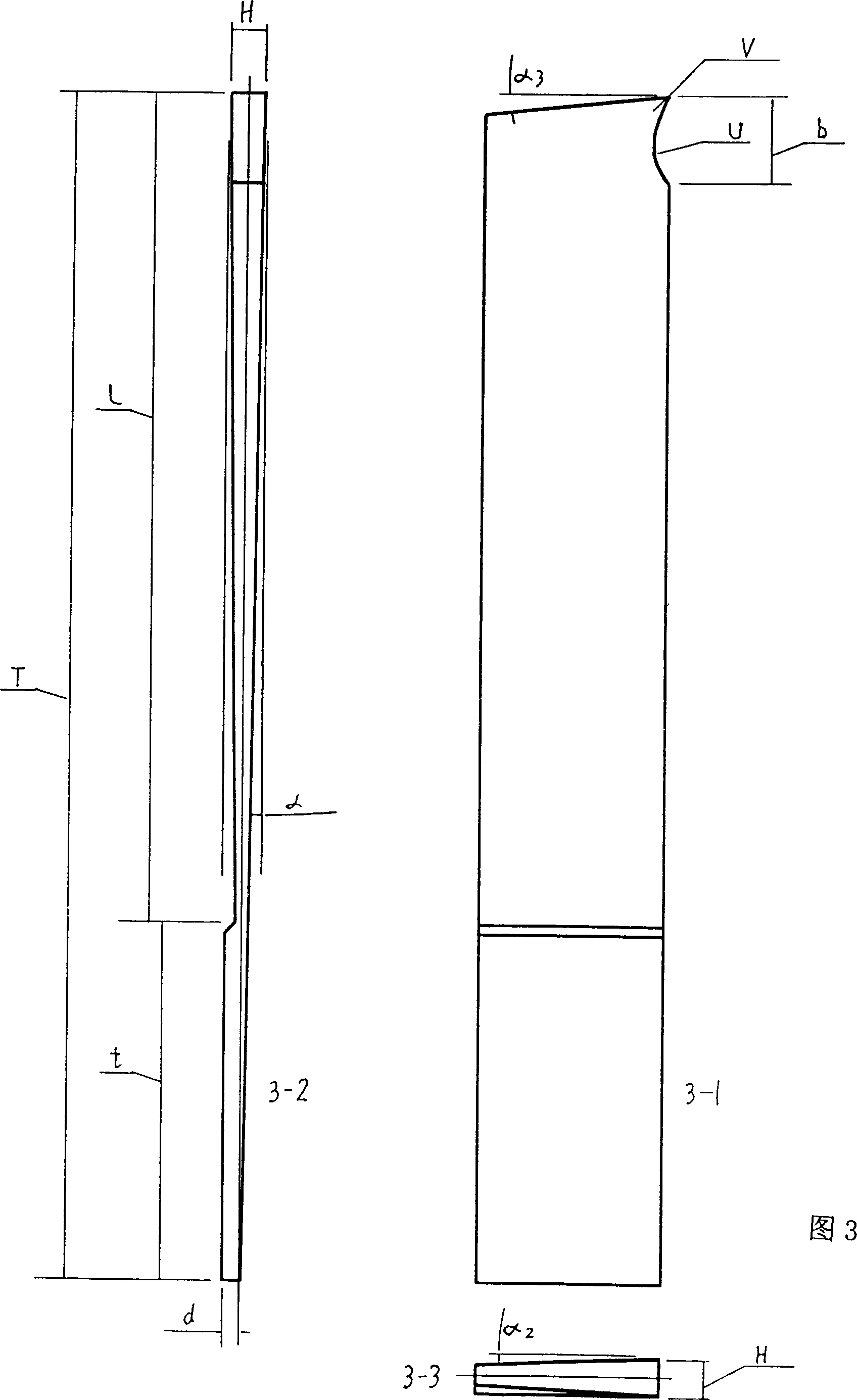

[0012] As shown in the figure, Fig. 1 is the front view and side view of the combined cutting tool with reinforced knife tail shaping, A is the body of the reinforced knife tail cutter, B is the fixture, and the knife body A is inserted into fixture B; Fig. 3 The cutter body shown is composed of two parts, the cutter section L and the cutter tail section t, and there is no transverse angle α in front of the cutter tail section t. 2 , the characteristic is that the longitudinal angle α and the transverse angle α of the existing basic structure of the cutter 2 extended to the full length L of the new blade shape, in order to make H 2 >H 3 Reduce H by appropriately expanding section b 3 , so will never manually grind the longitudinal angle α and transverse angle α 2 knife shape. The success of the design of the reinforced knife tail shaping cutter lies in the addition of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com