Double edge compression end mill

A compression type, end mill technology, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of easy vibration, scrapped workpieces, swelled and delaminated, etc., to achieve balanced cutting force, not easy to vibrate, Glitch reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

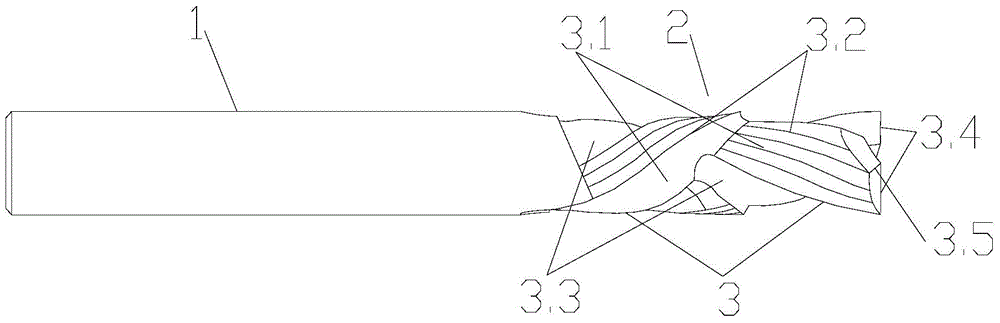

[0014] Such as figure 1 The shown double-edged compression end mill includes a handle 1 and a blade 2 at the front end of the handle 1. The blade 2 is provided with two helical cutting edges. The helical cutting edge is a segmented combined cutting edge. The blade 2 The spiral structure 3 is formed by connecting the front and back of the spiral structure 3 with the same structure. The spiral structure 3 is formed by two left-handed and right-handed spiral cutter bodies 3.1 spiraling half a circle on the same axis. A helical engraved back 3.2, the edges of the helical cutter body and the engraved back are cutting edges, all edges are cutting edges, and a helical chip relief groove 3.3 is formed between the two helical cutter bodies 3.1 , the edges and side edges of all the helical cutter bodies form the helical cutting edge of the double-edged compression end mill, the helical cutting edge is a discontinuous cutting edge, and the circumferential angles of the connecting surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com