Segmental drilling method and drilling machine for thick plate

A drilling method and drilling machine technology, applied in drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve the problems of short drilling stroke, low processing efficiency, high scrap rate, etc., and achieve Reduce the impact of axial force, improve processing efficiency, and ensure the effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

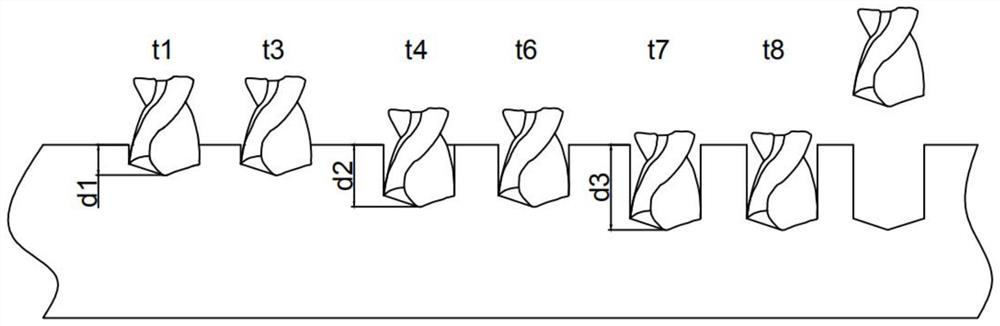

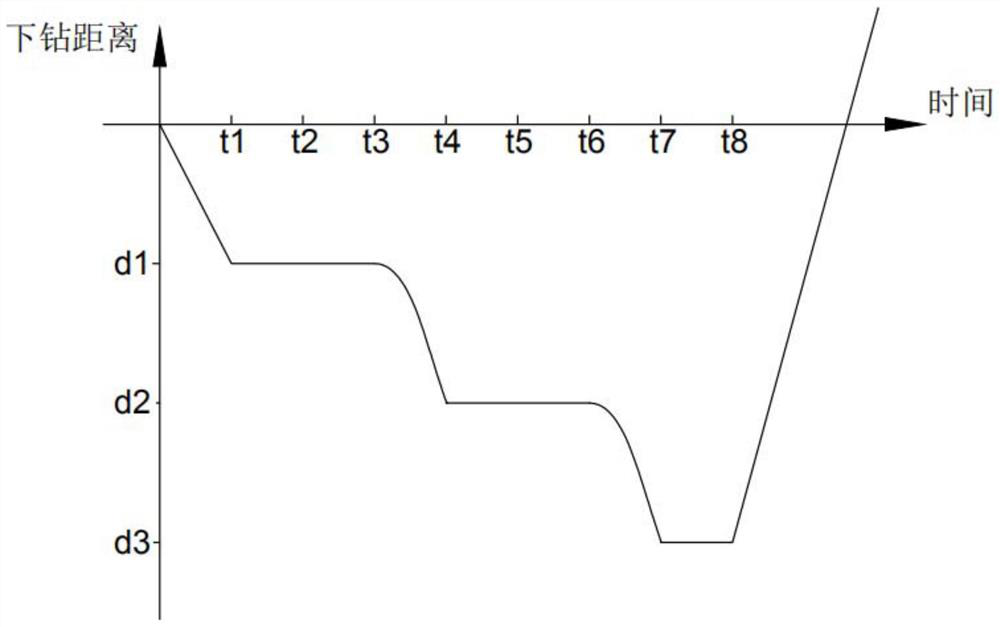

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0028] This embodiment provides a segmental drilling method for a thick plate, comprising the following steps:

[0029] Step 1: The tool drills into the plate for a certain distance at the first speed, maintains the position of the tool and maintains the first speed for a period of time;

[0030] Step 2:

[0031] Reduce the tool speed to the second speed;

[0032] While the tool is drilling into the plate, gradually increase the drilling speed of the tool until it reaches the set drilling speed, and gradually increase the tool speed to the first speed, the tool continues to drill into the plate for a certain distance, maintain the position of the tool and maintain the first speed for a period of time ;

[0033] Repeat step 2 until the tool drills down to the final depth.

[0034] After the tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com