A hydraulic magnesium ingot cutting machine

A cutting machine and magnesium ingot technology, applied in turning equipment, metal processing machinery parts, clamping, etc., can solve the problems of poor shear resistance, increased production cost, and reduced cross-sectional area, so as to achieve easy processing and save time , The effect of improving cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

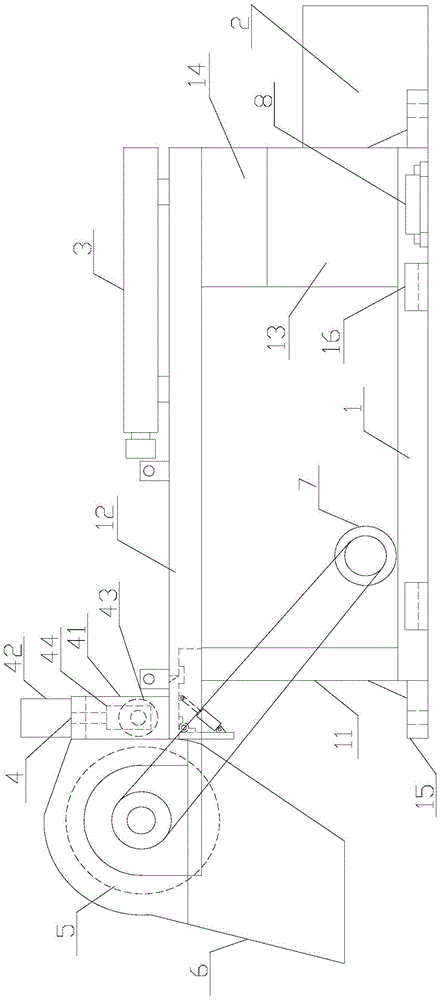

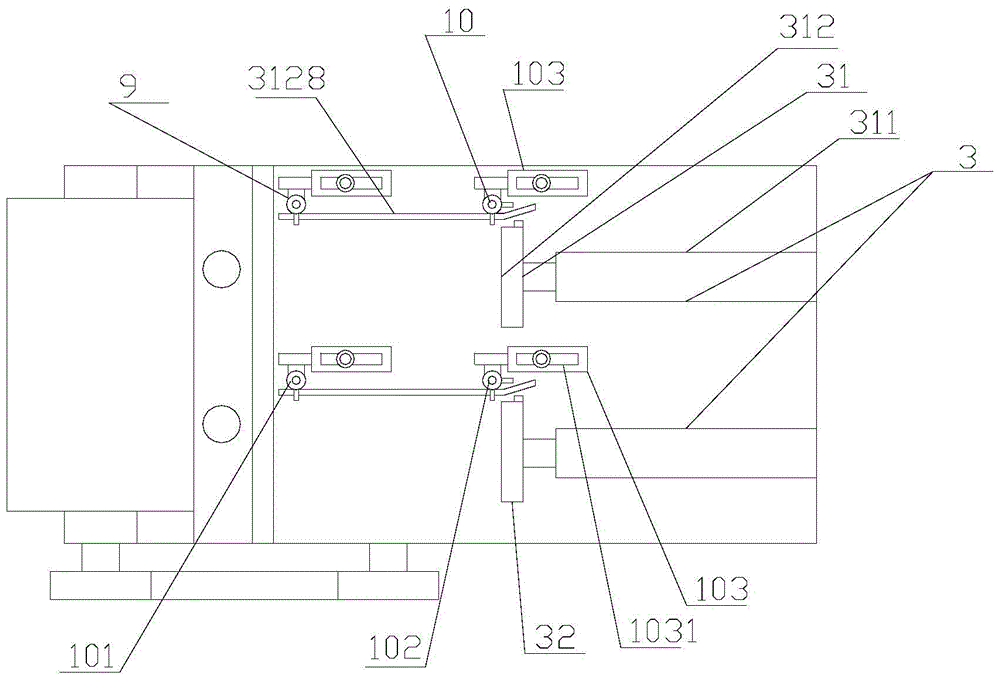

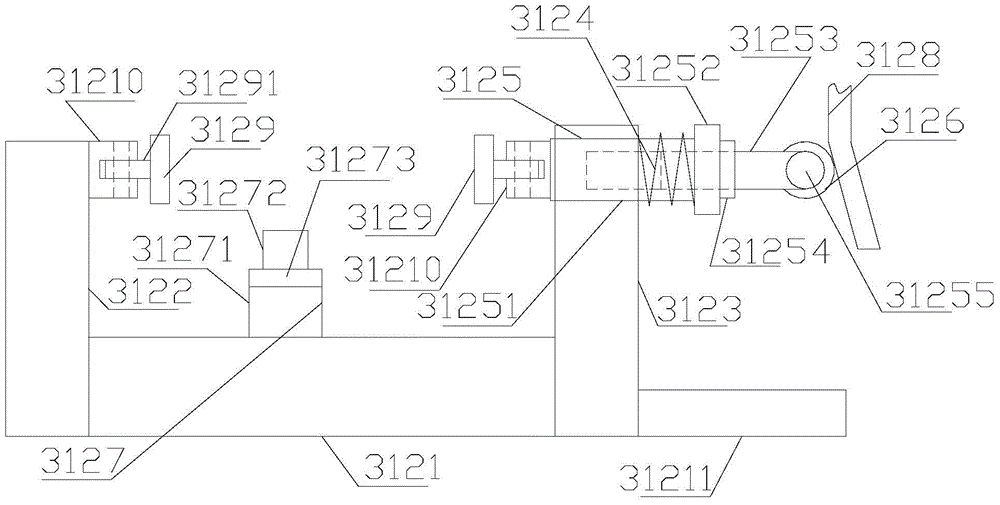

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 , a hydraulic magnesium ingot cutting machine of the present invention comprises a frame 1, a hydraulic station 2, a pushing device 3, a pressing mechanism 4, a knife roller 5, a collecting hopper 6, a motor 7 and an adapter plate 8, and the frame The front end of 1 is provided with cutter roller 5 and collecting hopper 6, and described collecting hopper 6 is arranged at the bottom of cutter roller 5, and described cutter roller 5 is connected with motor 7 transmission, and the platform of described frame 1 is provided with pressing mechanism 4. The pressing mechanism 4 is close to the knife roller 5, the rear part of the platform of the frame 1 is provided with a pushing device 3, the rear lower part of the frame 1 is provided with an adapter plate 8, and the hydraulic station 2 The adapter plate 8 is connected with the adapter plate 8 through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com