Locomotive wheel CNC turning repair equipment

A locomotive wheel and equipment technology, which is applied in the field of locomotive maintenance and locomotive wheel set maintenance, can solve the problems of insufficient machining accuracy, high investment cost, and difficulty in positioning and alignment, and achieve high machining accuracy, low investment cost, and structural integrity. Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

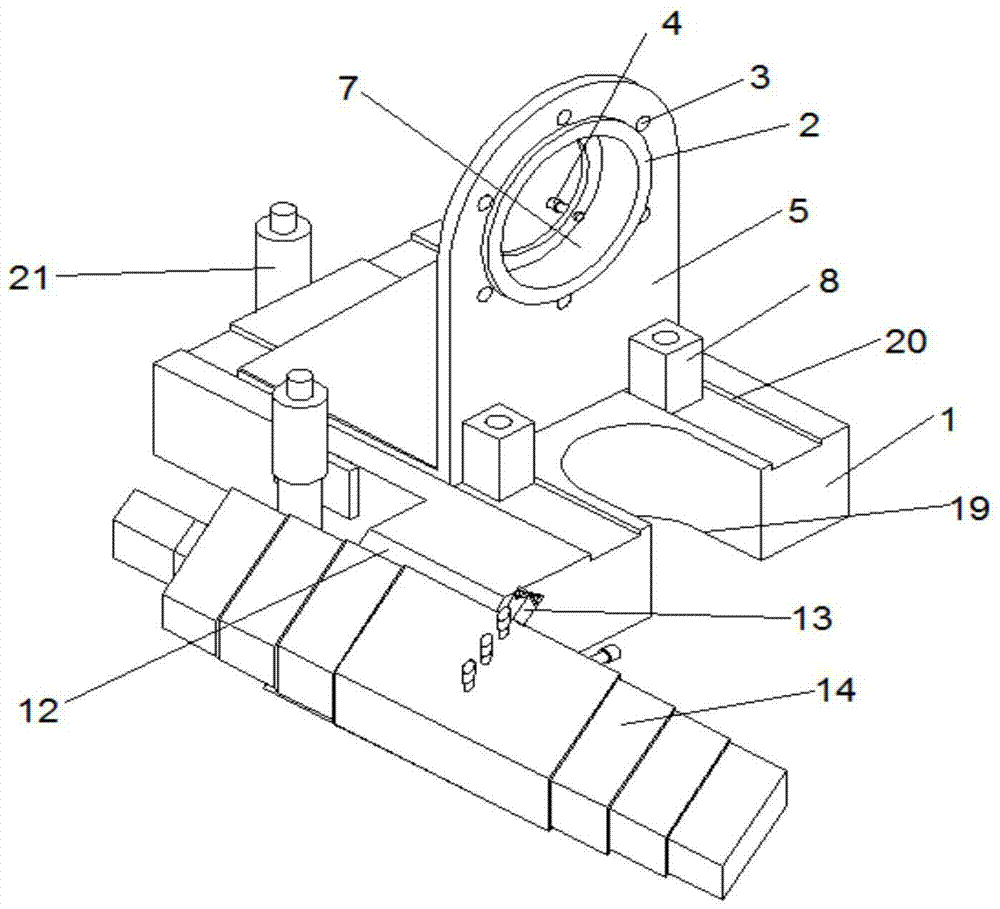

[0024]Below, take a kind of non-locomotive own power drive and be used for DF4DH4347 internal combustion locomotive, the locomotive wheel of JM3 tread rim curve as an example (1050 millimeter locomotive wheel diameter), introduce its technical scheme in detail.

[0025] Key parameters of each main component:

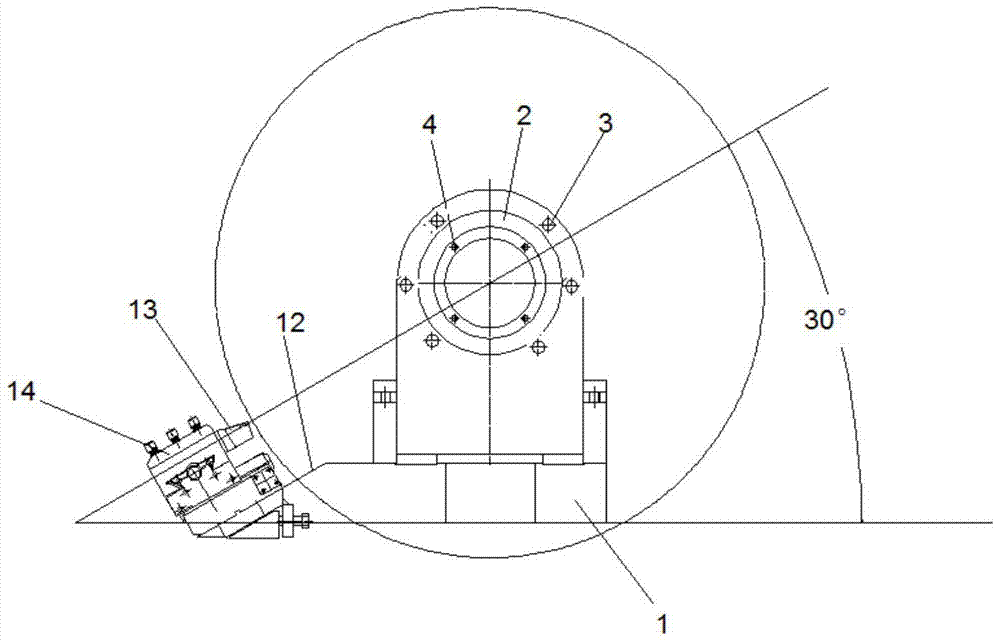

[0026] Machine base: length 1293mm, width 825mm, height 292mm; "U" opening width 180mm, depth 200mm, set in the center along the width direction of the machine base; slideway width 215mm; the inclination angle of the inclined surface 2 of the knife table installation surface 30 degrees;

[0027] Positioning bending plate: length 350mm, width 375mm, center height 464mm;

[0028] Support pile: 60*60*180mm square column;

[0029] The drive system includes: GS112M-4 motor; XWD7-87 reducer (speed ratio: 1:87);

[0030] The functions of CNC machining system include servo motor: ISMS1-40B30CB-U231Z (power: 400 watts, speed: 0-3000RPM, frequency: 50Hz); CNC box: FM-CNC208 dual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com