Skipping line-rolling device

A jumping and rolling line technology, which is applied in printing, rotary printing machines, printing machines, etc., can solve the problems of short service life of the blade, inability to cut the edge of the paper, and easy chipping of the blade, and achieve simple and compact structure, low cost, The effect of long wear life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

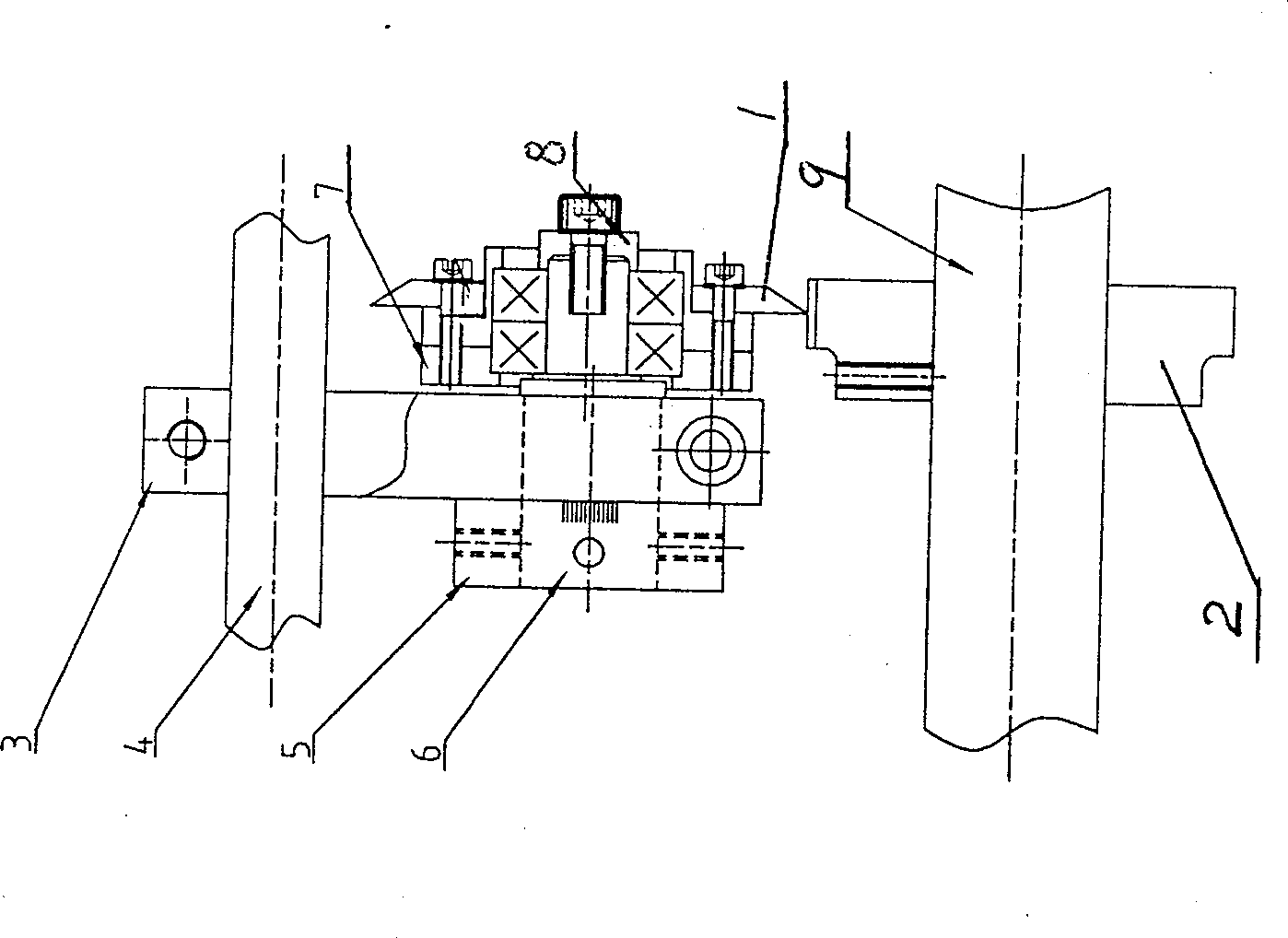

[0011] like figure 1 As shown, it is a structural schematic diagram of a jump-type rolling device, which is composed of a blade 1, a cam anvil 2, a connecting block 3, a fixed shaft 4, a positioning cap 5, an eccentric knife shaft 6, Bearing 7, gland 8 and anvil shaft 9 are composed.

[0012] First put the fixed shaft 4 through the connecting block 3 and then lock it with screws, then put the eccentric knife shaft 6 into the hole on the connecting block 3, fix it with the positioning cap 5 and pass it through the connecting pin and tighten it with the top screw. A bearing 7 is installed at the other end, the blade 1 is a round blade, which is fastened to the bearing 7 by screws, the gland 8 is fixed to the center of the blade 1 by screws, and the cam anvil 2 is set directly under the blade 1, and the anvil shaft 9 passes through cam anvil 2, and fix the cam anvil 2 with the top screw.

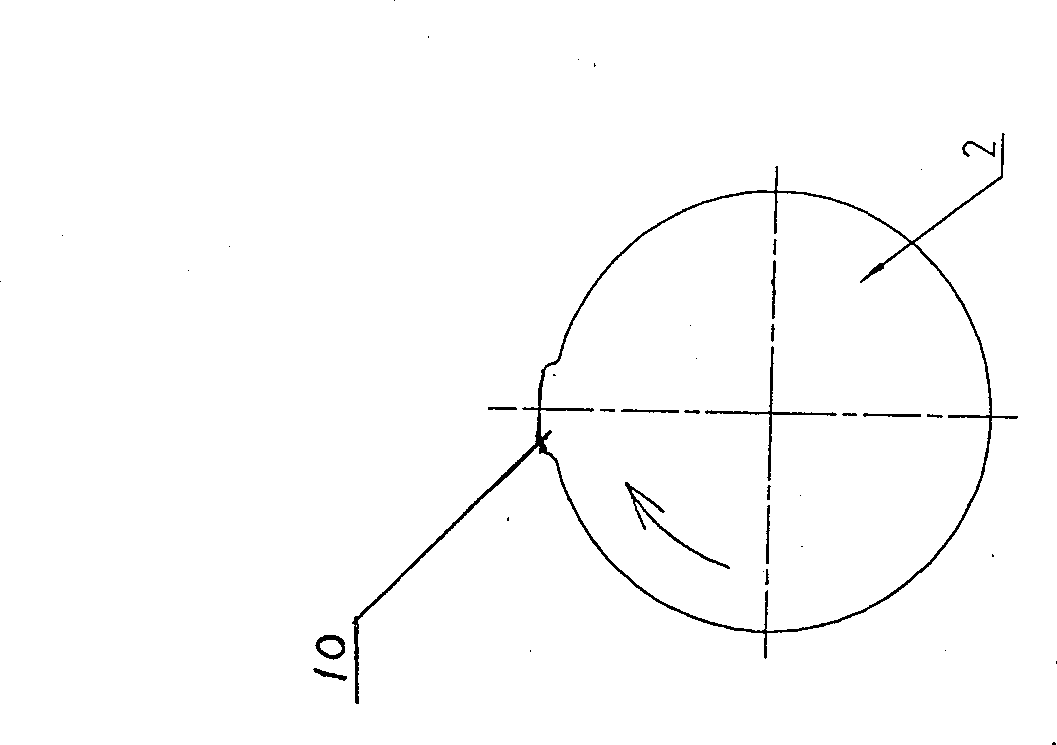

[0013] like figure 2 As shown, it is a schematic diagram of the structure of the cam an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com