Floating boring tool structure for inner wall of steel tube

A steel pipe inner wall and boring tool technology, applied in the direction of tool holders, etc., can solve the problems of poor processing accuracy and processing efficiency, poor processing accuracy of the steel pipe inner wall, troublesome disassembly, etc., to improve processing accuracy and processing efficiency, improve processing Accuracy and processing efficiency, the effect of not easy to break the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

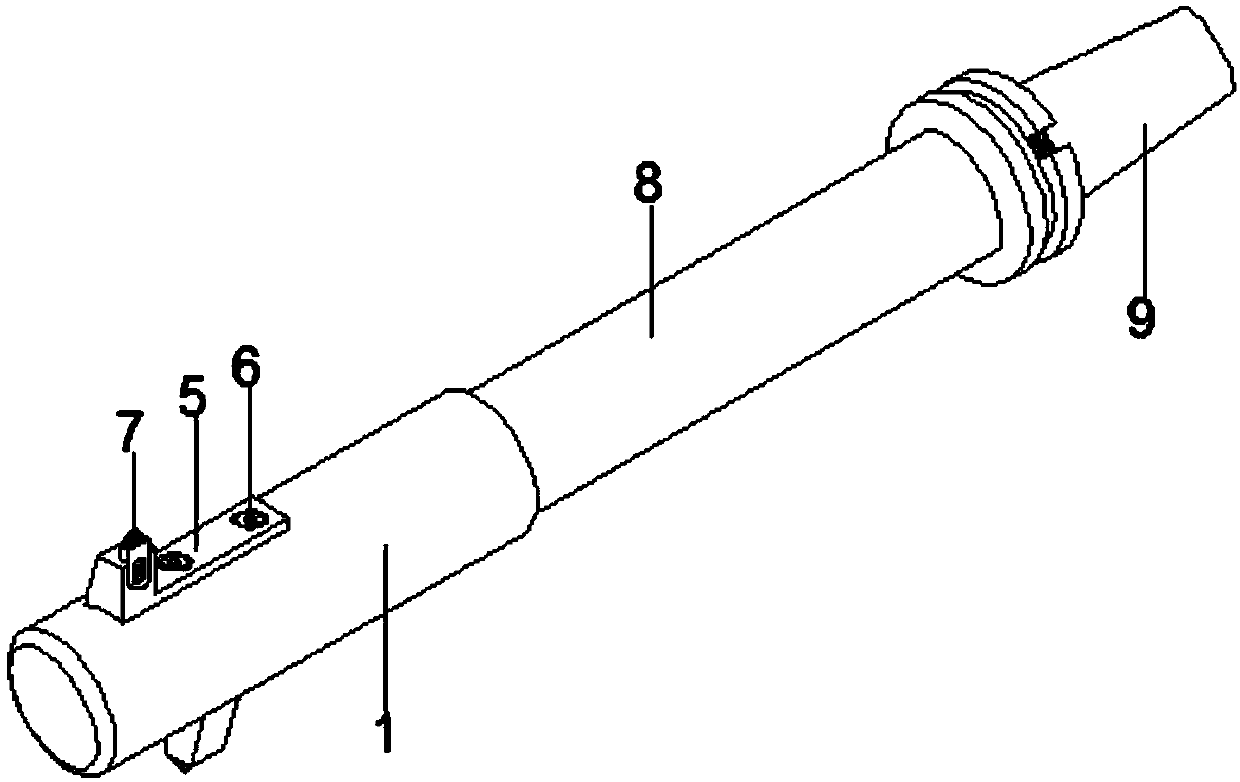

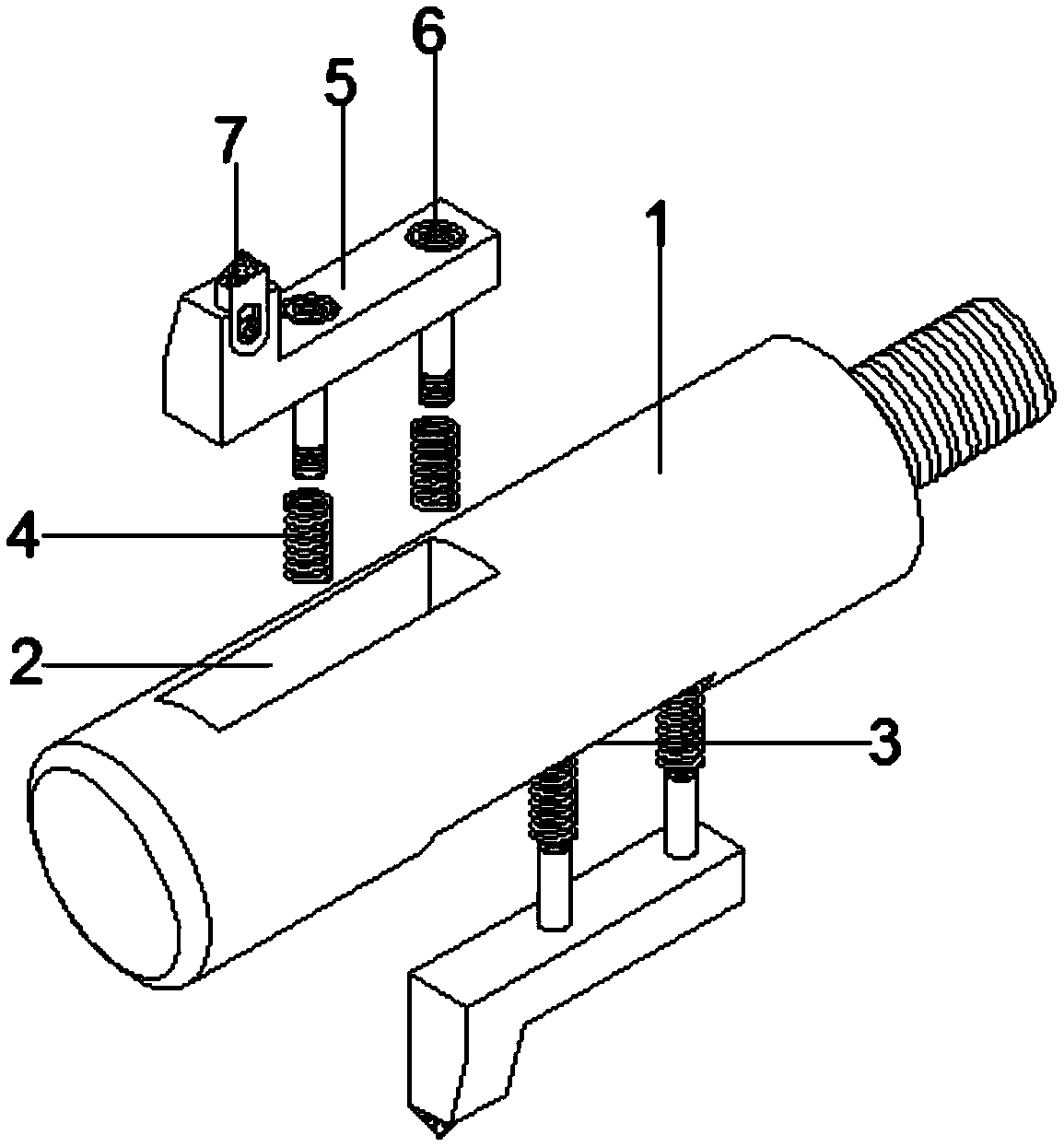

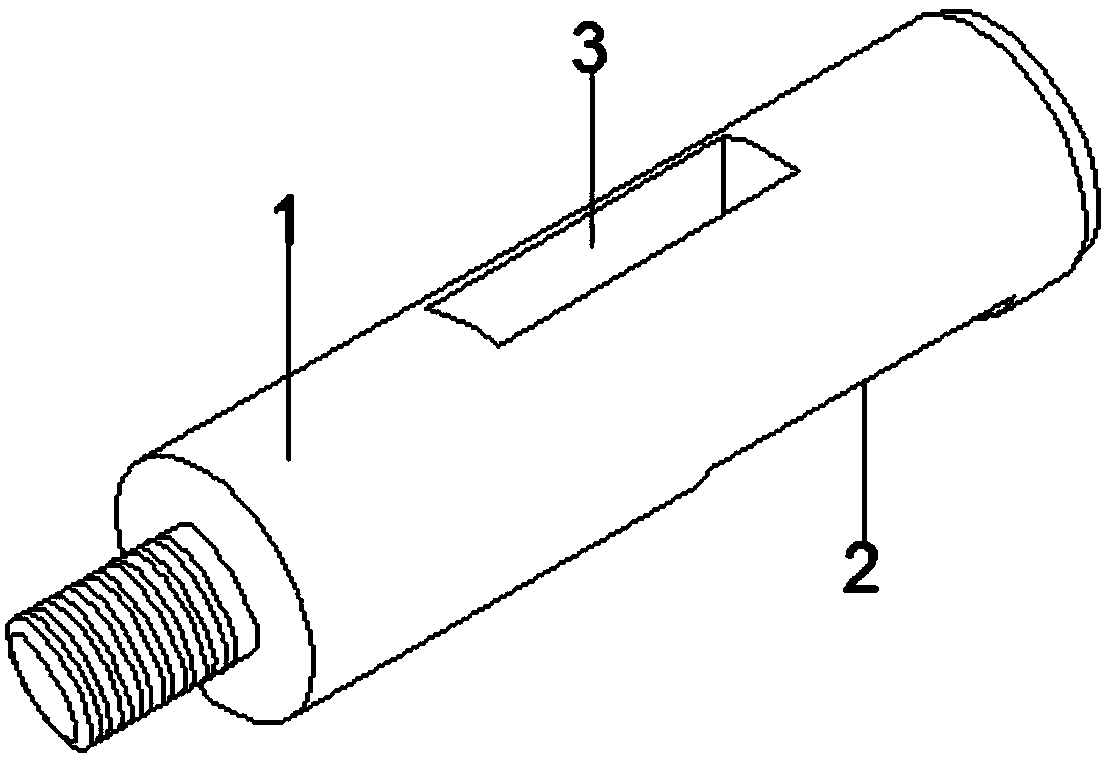

[0033] A steel pipe inner wall floating boring tool structure, including: tool bar 1, first tool slot 2, second tool slot 3, spring 4, tool seat 5, half shaft bolt 6, tool head 7, extension rod 8, taper handle 9 , cutter head groove 501; the first cutter groove 2 is located at the upper inner position of the cutter rod 1, and the first cutter groove 2 and the cutter rod 1 are integrated; the second cutter groove 3 is located at the lower inner position of the cutter rod 1 , and the second sipe 3 is integrated with the knife bar 1; the spring 4 is respectively installed inside the first sipe 2 and the second sipe 3, and the spring 4 is connected to the first sipe 2 and the second sipe 3 Through the half-axis bolt 6; the tool seat 5 is respectively installed inside the first sipe 2 and the second sipe 3, and the knife seat 5 and the first sipe 2 and the second sipe 3 are penetrated by the half-axis bolt 6. connected; half-shaft bolts 6 are respectively installed inside the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com