Micro-diameter both-edge tapered ball cutter

A taper and micro-diameter technology, applied in the direction of saw blades, can solve the problems of micro-diameter ball knives that are easy to break, poor processing effect, and low cutting efficiency, and achieve the effects of improving processing effect, high cutting efficiency, and improving chip removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

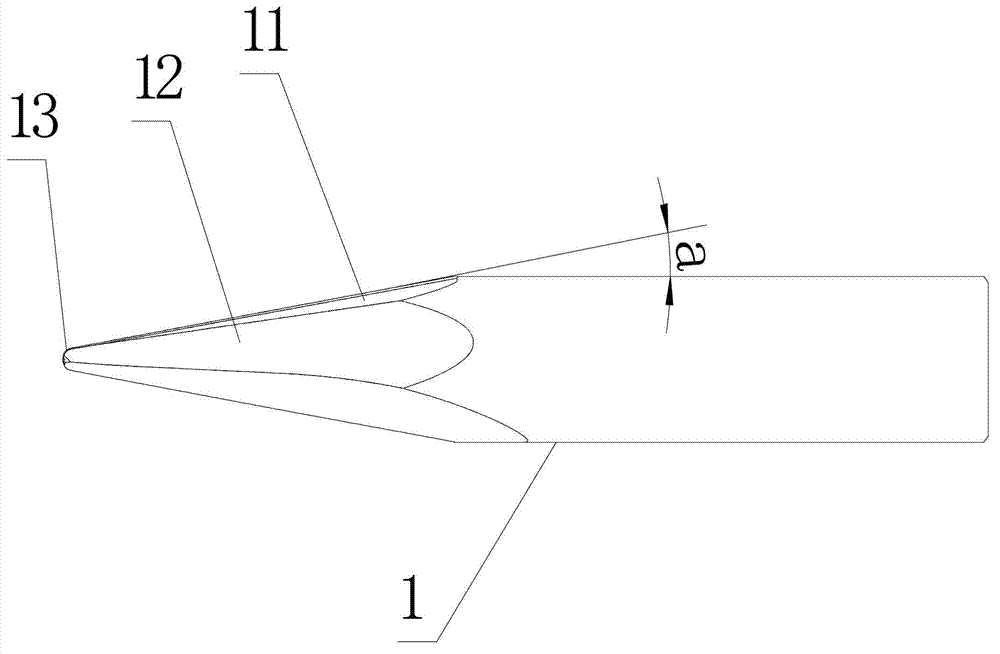

[0012] Such as figure 1 As shown, the micro-diameter double-edged taper ball knife includes a knife body 1. The knife body 1 is provided with two sets of cutting edges 11, and straight grooves 12 respectively arranged in the middle of the two sets of cutting edges 11, and the two sets of cutting edges 11 and the knife The angle of taper formed between the horizontal planes of the body 1 is 3-7°, the front end of the cutter body 1 is provided with a ball head 13, and the diameter of the ball head 13 is 0.3-0.5mm. The two sets of blades 11 and The angle of taper formed between the horizontal planes of the cutter body 1 is 5°, the diameter of the ball head 13 is 0.4mm, the use effect is good, and the processing is convenient. The positive rake angle of the cutter body 1 is 20°. The cross section of the relief angle of the body 1 is a circular arc, which improves the cutting strength of the cutter body 1, reduces the cutting resistance of the cutter body 1 during the cutting proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com