An ultra-high cutting verticality integral ultra-thin resin grinding wheel and its preparation method

A resin grinding wheel and verticality technology, which is applied in the field of abrasive tool manufacturing, can solve the problems of no relevant research on cutting verticality, thick fiber mesh thickness, inapplicability, etc. The effect of wheel rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

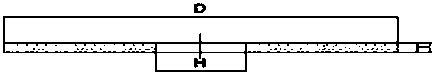

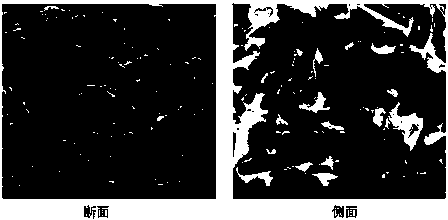

[0022] An ultra-high cutting verticality integral ultra-thin resin grinding wheel, which is composed of the following volume percentage raw materials: 2000# diamond 20%, phenolic resin 50%, carbon fiber 15% (diameter 10 microns, length 200 microns, aspect ratio 20 :1) and glass fiber 15% (diameter 10 microns, length 200 microns, aspect ratio 20:1).

[0023] The preparation method of the above-mentioned ultra-high cutting verticality integral ultra-thin resin grinding wheel, which comprises the following steps:

[0024] 1) Weigh the raw materials in proportion and mix them evenly;

[0025] 2) Forming: put the mixture obtained in step 1) into a mold for hot pressing to obtain a grinding wheel blank; the hot pressing temperature is 200°C, the hot pressing time is 15 minutes, and the hot pressing pressure is 10 MPa;

[0026] 3) The grinding wheel blank obtained in step 2) is hardened according to the designed hardening curve, and finally, after end face processing, inner and oute...

Embodiment 2

[0029] An ultra-high cutting verticality integral ultra-thin resin grinding wheel is composed of the following volume percentage raw materials: 200# diamond 25%, phenolic resin 40%, carbon fiber 10% (diameter 10 microns, length 400 microns, aspect ratio 40 :1) and glass fiber 15% (diameter 10 microns, length 400 microns, aspect ratio 40:1), graphite 10%.

[0030] Refer to Example 1 for the preparation method of the above-mentioned ultra-high cutting verticality integral ultra-thin resin grinding wheel.

Embodiment 3

[0032] An ultra-high cutting verticality integral ultra-thin resin grinding wheel, which is composed of the following volume percentage raw materials: 1000# cubic boron nitride 10%, polyimide resin 45%, carbon fiber 20% (diameter 5 microns, length 300 micron, aspect ratio 60:1) and glass fiber 20% (diameter 5 microns, length 300 microns, aspect ratio 60:1), graphite 5%.

[0033] Refer to Example 1 for the preparation method of the above-mentioned ultra-high cutting verticality integral ultra-thin resin grinding wheel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com