Backdrilling method, device and equipment of printed circuit board, and storage medium

A printed circuit board and back-drilling technology is applied in the fields of equipment and storage media, back-drilling methods for printed circuit boards, and devices, and can solve the problems of low back-drilling depth accuracy, low back-drilling program efficiency, etc., so as to reduce scrap risk, saving time in changing programs, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

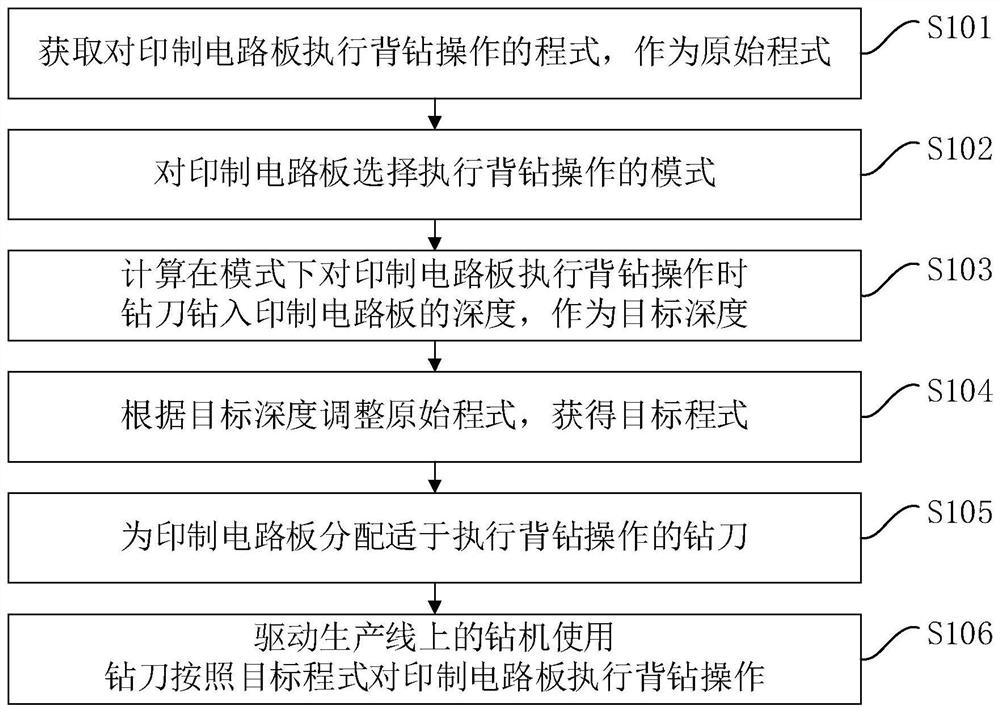

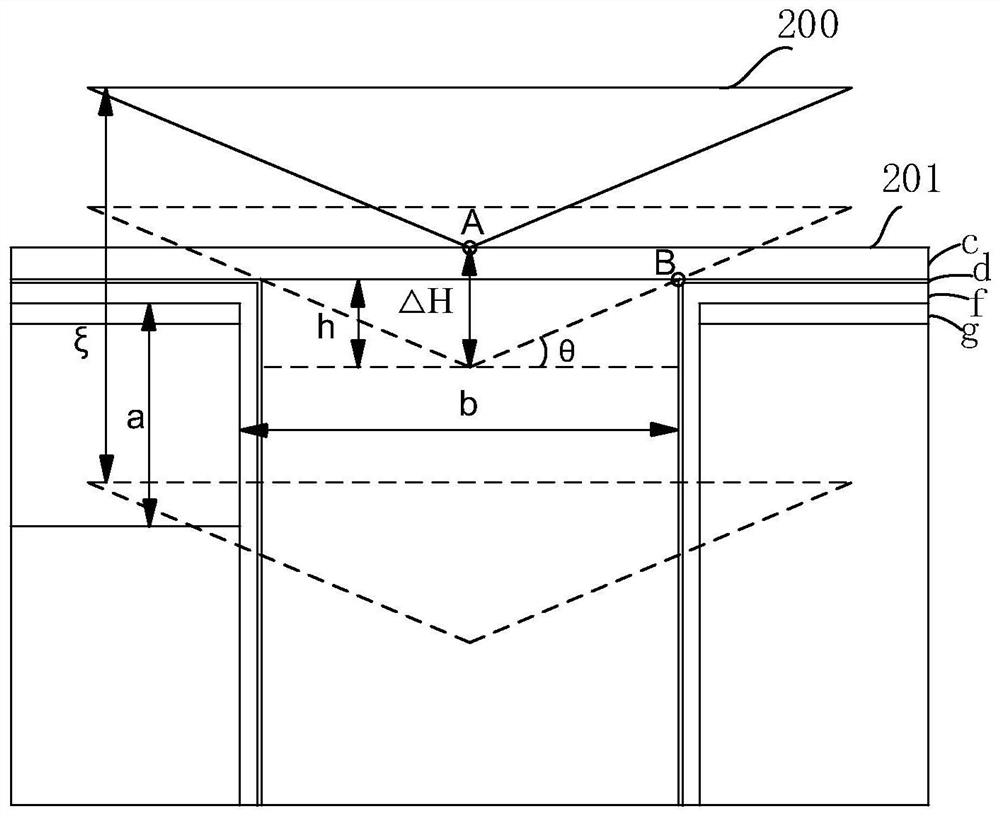

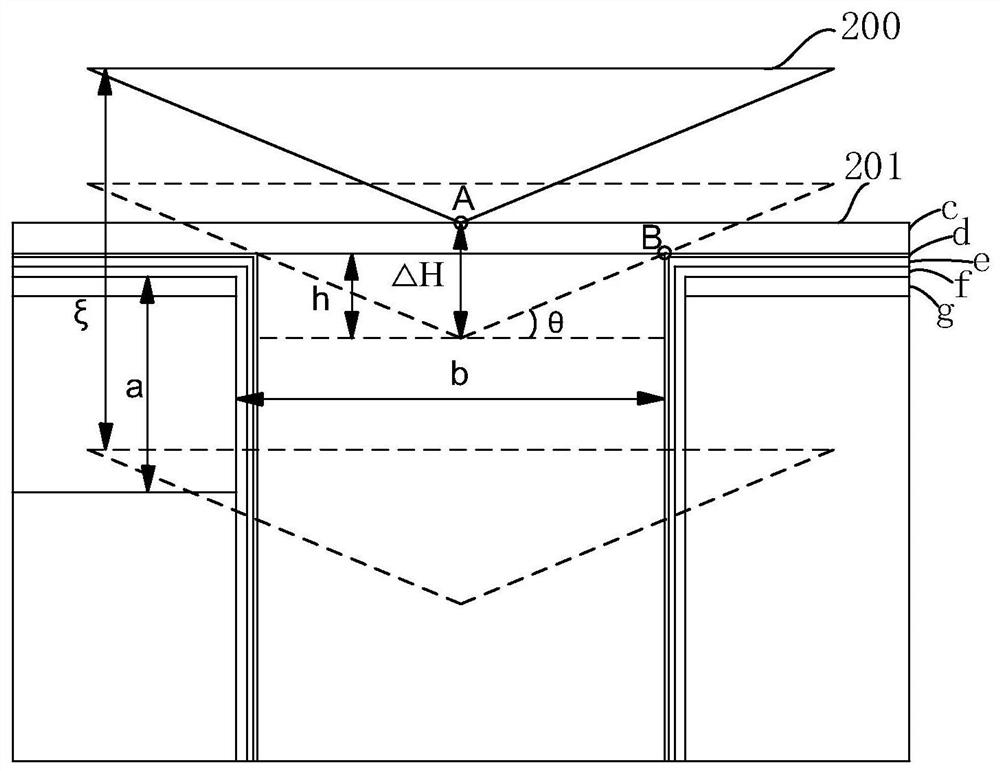

[0056] figure 1 This is a flow chart of a back-drilling method for a printed circuit board provided in Embodiment 1 of the present invention. This embodiment is applicable to the case of performing a back-drilling operation on a printed circuit board. The back-drilling device of the printed circuit board can be implemented by software and / or hardware, and can be configured in computer equipment, such as a server, a workbench, an industrial computer, a control system, etc. The method specifically includes Follow the steps below:

[0057] S101. Obtain a program for performing a back-drilling operation on the printed circuit board as an original program.

[0058] In the back-drilling process, positioning pins are usually set on the work surface of the drilling rig, holes are punched in the printed circuit board that needs to be back-drilled, and the holes on the printed circuit board are set on the positioning pins on the work surface. to secure the printed circuit board. Furt...

Embodiment 2

[0092] image 3 A schematic structural diagram of a back-drilling device for a printed circuit board provided in Embodiment 2 of the present invention, the back-drilling device may specifically include the following modules:

[0093] The printed circuit board information acquisition module 301 is used to acquire a program for performing a back-drilling operation on the printed circuit board as an original program;

[0094] a back-drilling mode determination module 302, configured to select a mode for performing a back-drilling operation on the printed circuit board;

[0095] a target depth calculation module 303, configured to calculate the depth that the drill drills into the printed circuit board when the back-drilling operation is performed on the printed circuit board in the mode, as the target depth;

[0096] a target program acquiring module 304, configured to adjust the original program according to the target depth to obtain a target program;

[0097] a drill distrib...

Embodiment 3

[0128] Figure 4 A schematic structural diagram of a computer device provided in Embodiment 3 of the present invention, such as Figure 4 As shown, the computer device includes a processor 400, a memory 401, a communication module 402, an input device 403 and an output device 404; the number of processors 400 in the computer device may be one or more, Figure 4 Take a processor 400 as an example; the processor 400, the memory 401, the communication module 402, the input device 403 and the output device 404 in the computer equipment can be connected through a bus or other means, Figure 4 Take the connection through the bus as an example.

[0129]The memory 401, as a computer-readable storage medium, can be used to store software programs, computer-executable programs and modules, such as the modules corresponding to the back-drilling method of the printed circuit board in the embodiment of the present invention (for example, such as image 3 The printed circuit board informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com