Structure of pressure-resistant oil tank and manufacturing method thereof

A manufacturing method and technology for fuel tanks, which are applied in the field of fuel tanks, can solve the problems of poor tensile force, quality, and scrapping of fuel tanks, and achieve the effects of improving connection tightness, high structural quality, and low scrapping risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

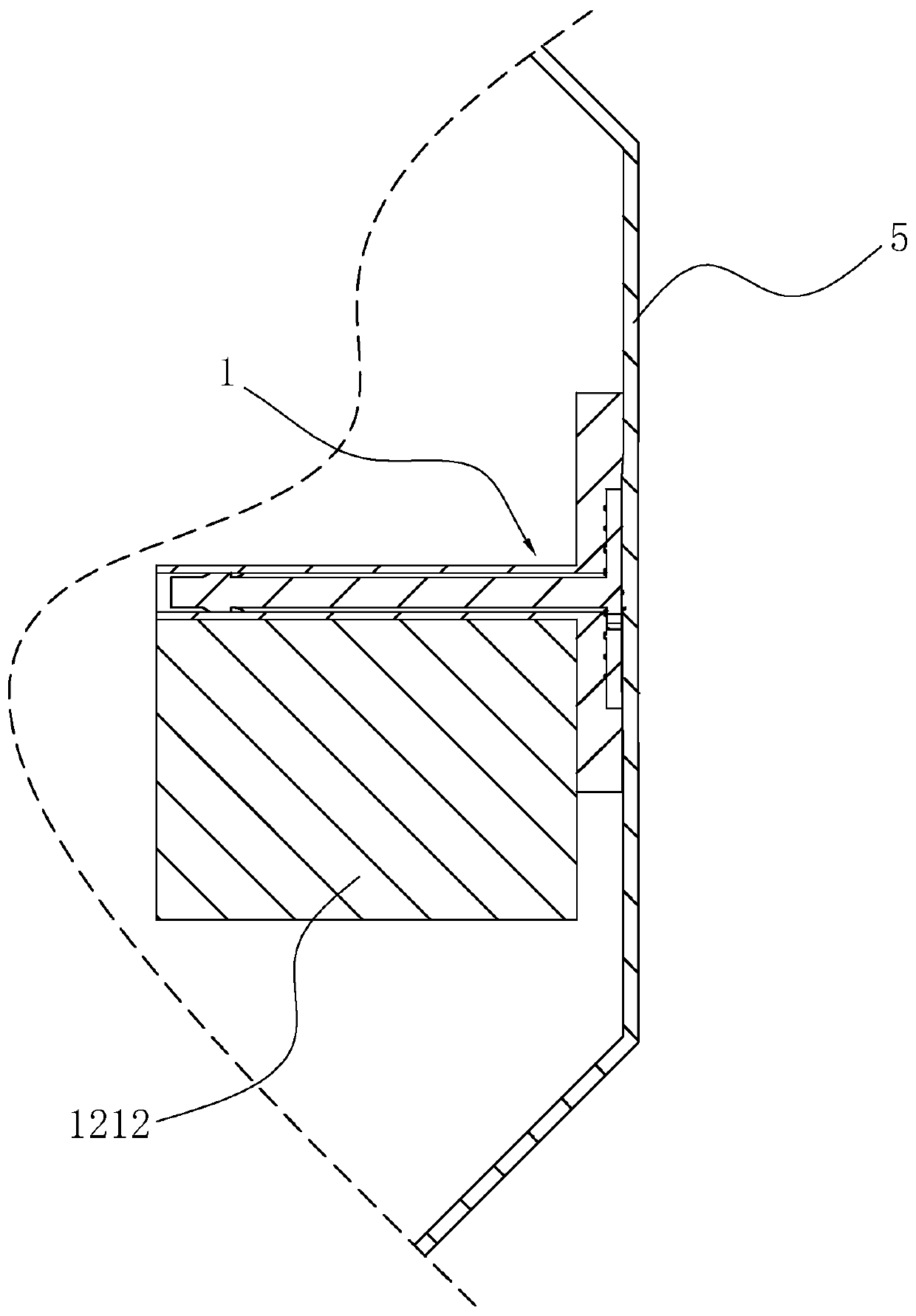

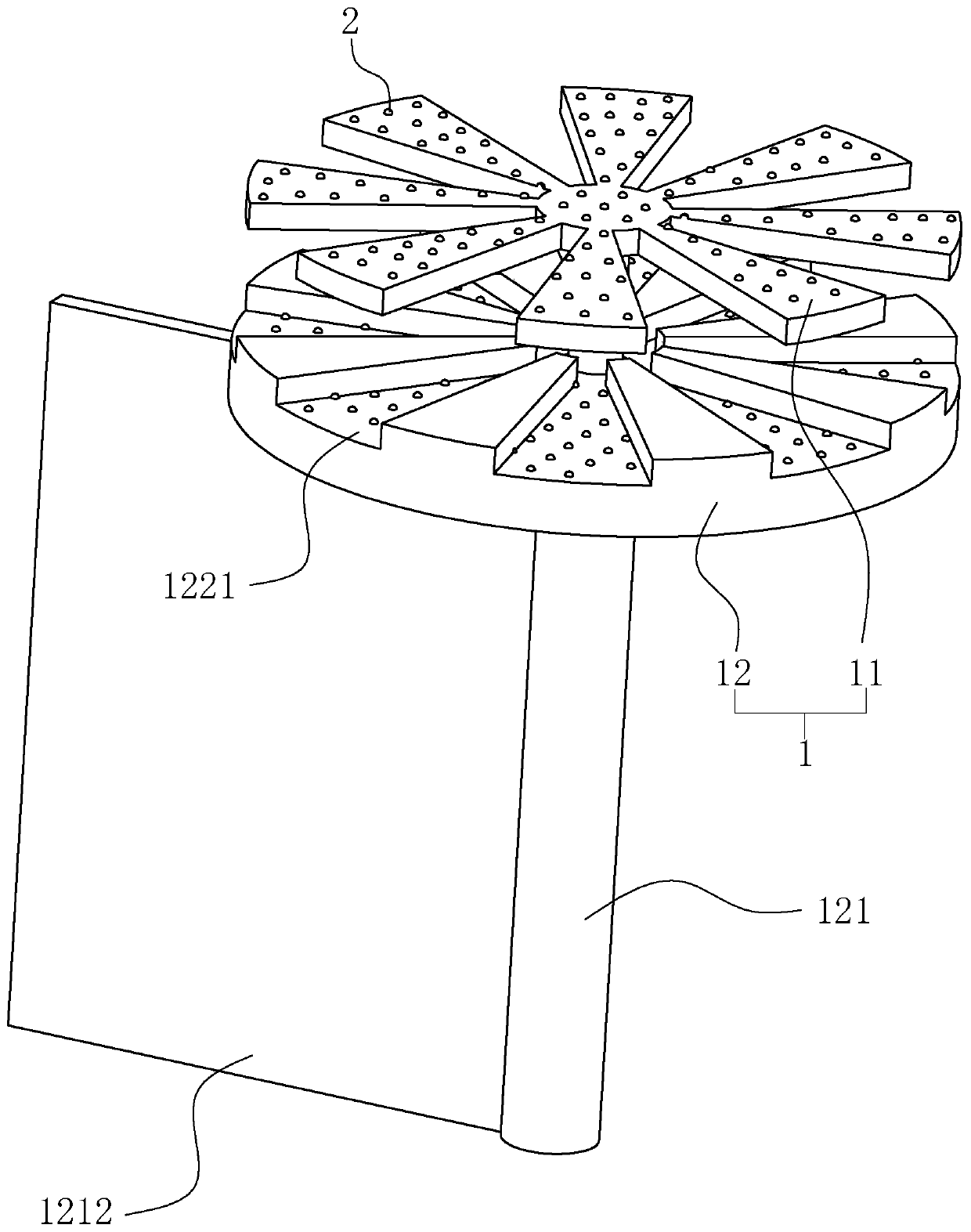

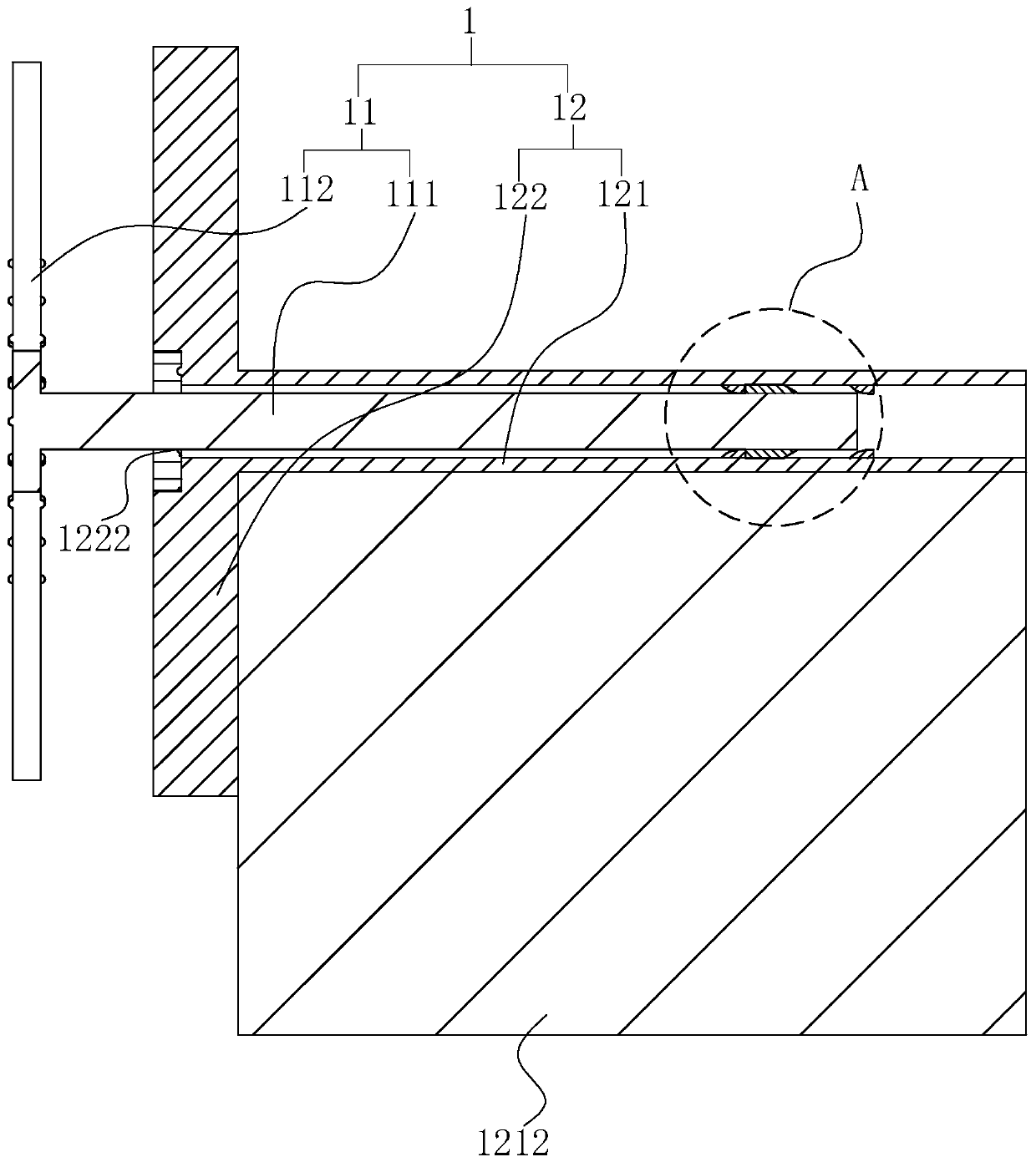

[0051] A structure of a pressure-resistant oil tank, such as figure 1 As shown, including the fuel tank body 5, the inner wall of the fuel tank body 5 is fixedly provided with at least one connecting piece 1, and the connecting piece 1 is scalded and fixed when the fuel tank body 5 is still in the state of the molten parison, so that the connecting piece 1 and the fuel tank body 5 can be integrally fixed, and the connecting piece 1 can withstand high tensile force, so that when the fuel tank body is used in a PHEV vehicle, it can be applied to a larger negative pressure to positive pressure range, thereby improving the strength and quality of the fuel tank body 1 , the anti-wave plate 1212 can also be fixedly connected on the connecting piece 1 to play the role of anti-wave, or other components can be fixed on the connecting piece 1 as required. Compared with the prior art, the connection method between the connector 1 and the fuel tank body 5 does not require a welding proces...

Embodiment 2

[0059] A method for manufacturing a pressure-resistant oil tank, comprising the following steps:

[0060] S1. Install the connector 1. When installing, install the installation rod 111 through the socket 1222 and insert it into the sleeve 121 until the snap ring 1111 passes over the shoulder 1211 once. At this time, the gap between the installation disk 112 and the mating disk 122 is the installation disk. Radius distance of 112;

[0061] S2. Send the connector 1 into the blow mold 3. The blow molding machine is equipped with a feeder 4 for sending the connector 1 into the blow mold 3. The feeder 4 is fixed with a temporary connector 1 and drives the connection. Part 1 translational feeding drive 41, the feeding drive 41 is preferably a cylinder; as Figure 7 shown;

[0062] S3, the extruder extrudes the molten parison, and then the parison is put into the blow mold 3, and the blow mold 3 starts the mold closing process; the blow mold 3 is provided with a shaft hole 31 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com