Method for repairing large-area damage of honeycomb sandwich structural part

A technology of honeycomb interlayer and structural parts, which is applied to household components, household appliances, weight reduction, etc., can solve the problem of small repair area, achieve the effect of avoiding secondary damage and reducing the risk of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

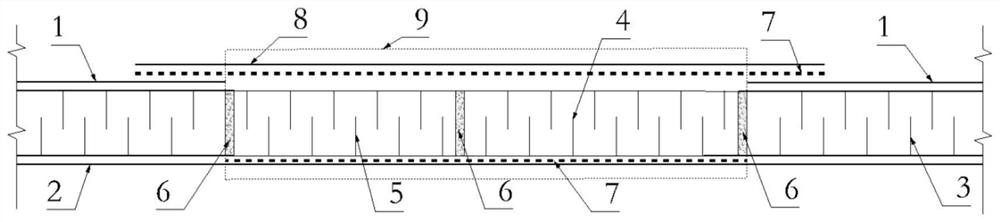

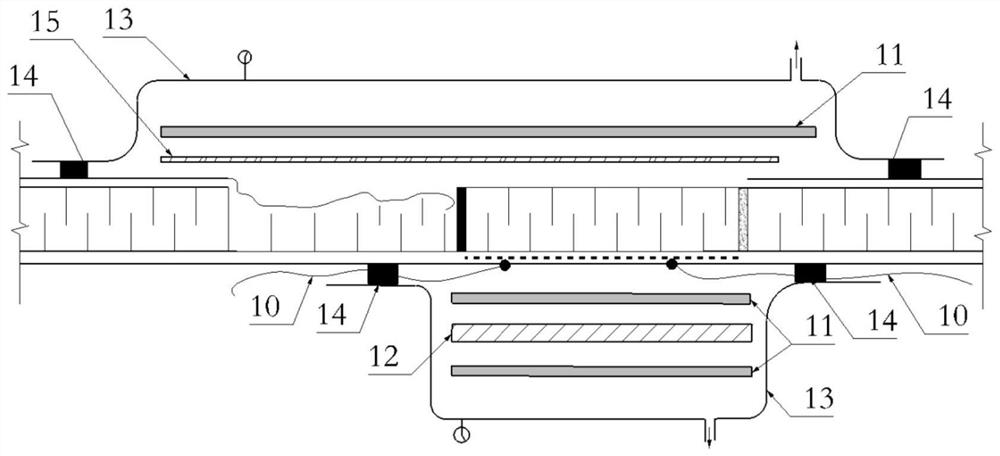

Embodiment 1

[0058] The tail beam of a certain type of helicopter has a honeycomb sandwich structure. The outer panel is made of aluminum alloy 2024T3 with a thickness of 0.4mm, the inner panel is made of aluminum alloy 5052H19 with a thickness of 0.1mm, and the sandwich is made of aramid paper honeycomb DHS251-142 with a thickness of 12mm. Due to a power failure, the plastic conduit inside the tail beam caught fire, and the tail beam suffered a large area of ablation damage, with a damage area of about 950×300mm. Heat up to 165°C with a hot-filler (hot-pressing blanket), evacuate (vacuum pump) and pressurize to 0.07Mpa, and then cure twice and splice two pieces of aramid paper honeycomb DHS251-142- with areas of 450×300mm and 500×300mm. 12. Aluminum alloy patch 5052H19 with a final curing area of 1050×400mm and a thickness of 0.4mm, such as Figure 5 shown.

[0059] Visible, this application:

[0060] 1) It breaks through the size limit of repairing damage by the conventional hone...

Embodiment 2

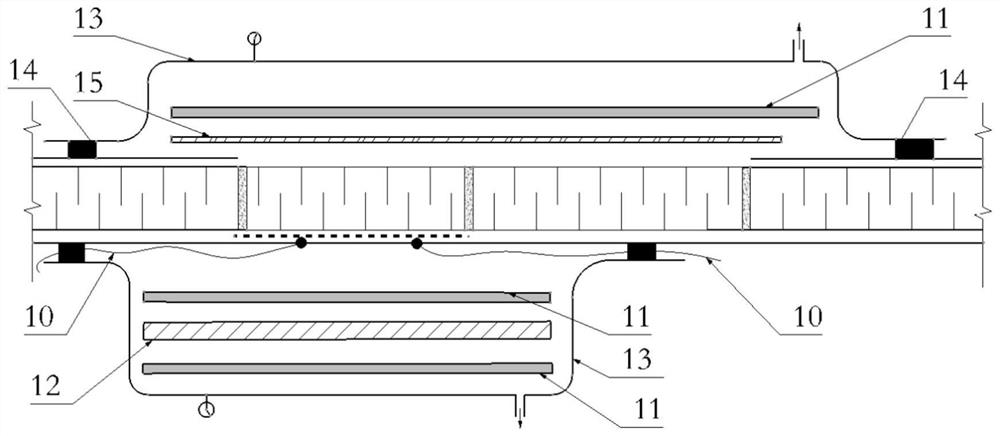

[0065] The floor of a certain type of UAV fuel tank is a honeycomb sandwich structure. The upper panel is made of aluminum alloy LY12 CZ with a thickness of 0.4mm, the lower panel is made of LY12 CZ with a thickness of 0.6mm, and the sandwich is made of aramid paper honeycomb NH-1-1.83 with a thickness of 12mm. Due to the excessive tightening torque of the bolts during equipment installation, the upper panel and the honeycomb collapsed in a large area, and the damage area was 750×350mm. Heat it to 110°C with a heat patching instrument (hot press blanket), and vacuumize it (vacuum pump) to pressurize it to 0.07Mpa , two pieces of aramid paper honeycomb NH-1-1.83-12 with an area of 350×350mm and 400×350mm were spliced twice, and finally an aluminum alloy patch LY12 CZ with an area of 850×450mm was cured and the thickness was 0.4mm.

[0066] To sum up, the present invention provides a method for heating with a heat repair instrument (hot press blanket), vacuuming (vacuum pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com