Flexible OLED display device assembling method

A technology for display devices and assembly methods, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve problems such as waste of cost, scrapped OLED body 100, poor bonding of chip-on-chip film 200, etc., to save production costs, The effect of improving assembly yield and reducing the risk of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

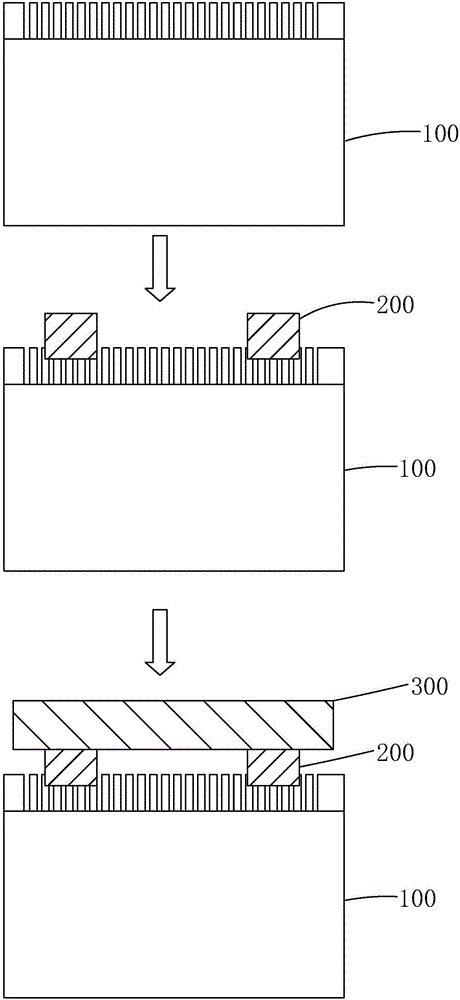

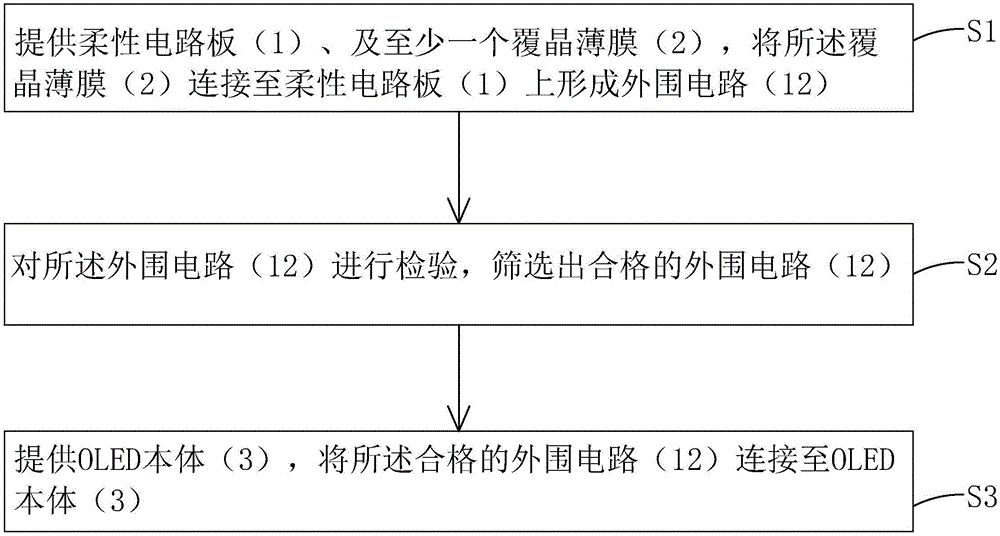

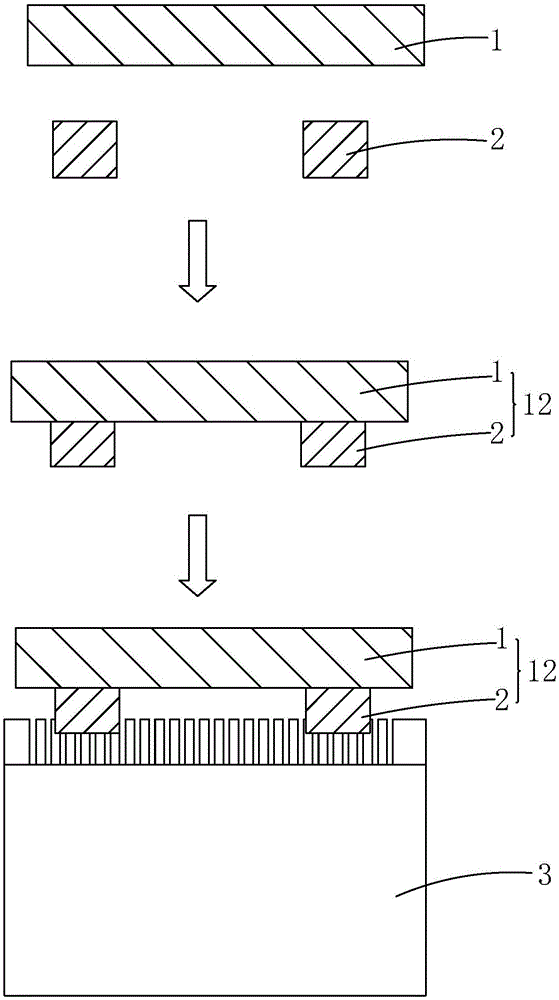

[0028] Please also see figure 2 and image 3 , the present invention provides a method for assembling a flexible OLED display device, comprising the following steps:

[0029] Step S1 , providing a flexible circuit board 1 and at least one chip-on-chip film 2 , and connecting the chip-on-chip film 2 to the flexible circuit board 1 to form a peripheral circuit 12 .

[0030] Specifically, in step S1, the chip-on film 2 is connected to the flexible circuit board 1 to form a peripheral circuit 12 by using a thermocompression welding process, that is, Bonding the chip-on film 2 and the flexible circuit board 1 .

[0031] Step S2 , inspecting the peripheral circuits 12 , and selecting qualified peripheral circuits 12 .

[0032] Specifically, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com