Water cooling roller

A technology of water-cooled rollers and rollers, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of large cross-sectional size differences of forgings, high production costs of water-cooled rollers, and increased motor power selection, etc., to achieve good strip shape , good airtight testability, and the effect of improving the yield of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

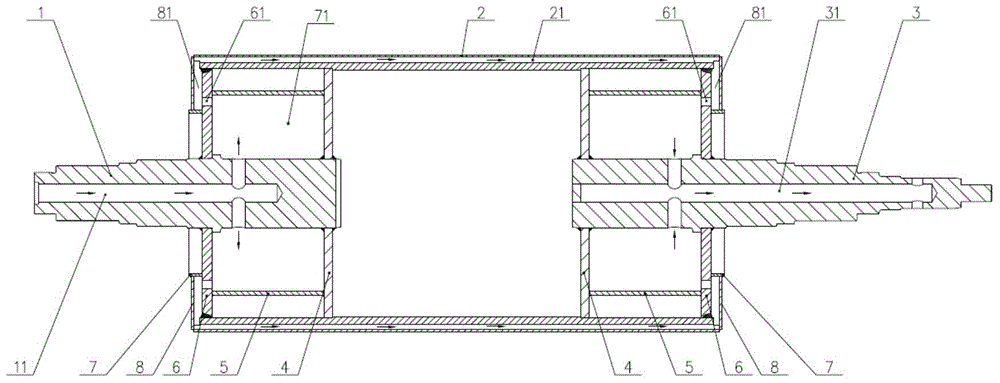

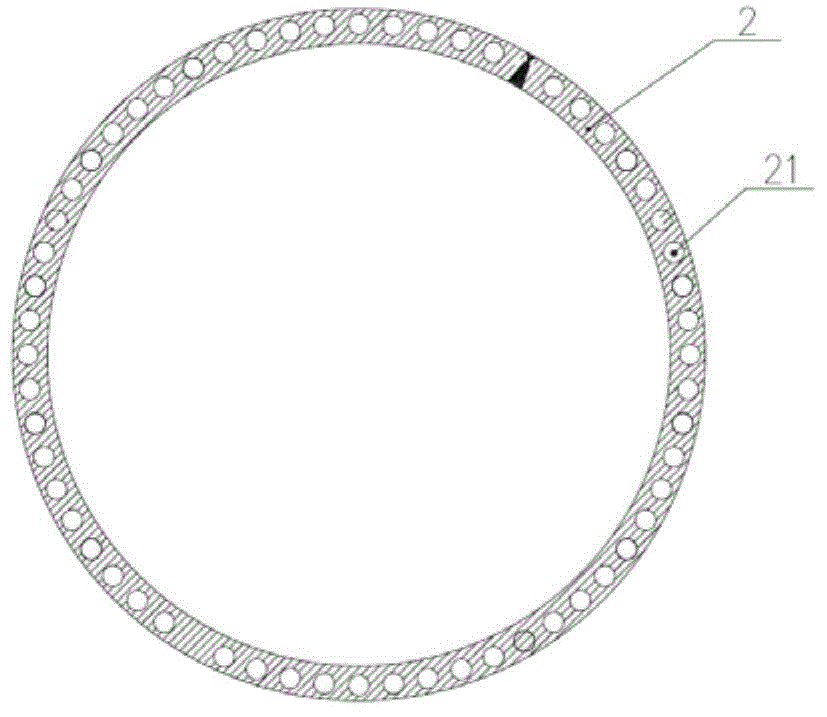

[0017] Such as figure 1 , figure 2 As shown, the water-cooled roller of the present invention includes an operating side shaft cylinder, a roller 2, and a transmission side shaft cylinder. The operation side shaft cylinder is composed of operation side shaft 1, inner end plate 4, outer end plate 6, cylinder 5, inner plate 7 and cover plate 8, and the transmission side shaft cylinder is composed of transmission side shaft 3, inner end plate 4, outer end Plate 6, cylinder 5, inner plate 7 and cover plate 8 are formed.

[0018] A first water channel 11 is provided inside the operation side shaft 1 , and the first water channel 11 communicates with the inner chamber 71 formed by the inner end plate 4 , the outer end plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com