Cold cathode X-ray tube and X-ray generating device

A technology of X-ray tubes and cold cathodes, which is applied in the direction of X-ray tubes, X-ray tube electrodes, X-ray tube components, etc., can solve the problems of short service life of cold-cathode X-ray tubes, reduce the risk of scrapping, The effect of improving the production pass rate and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

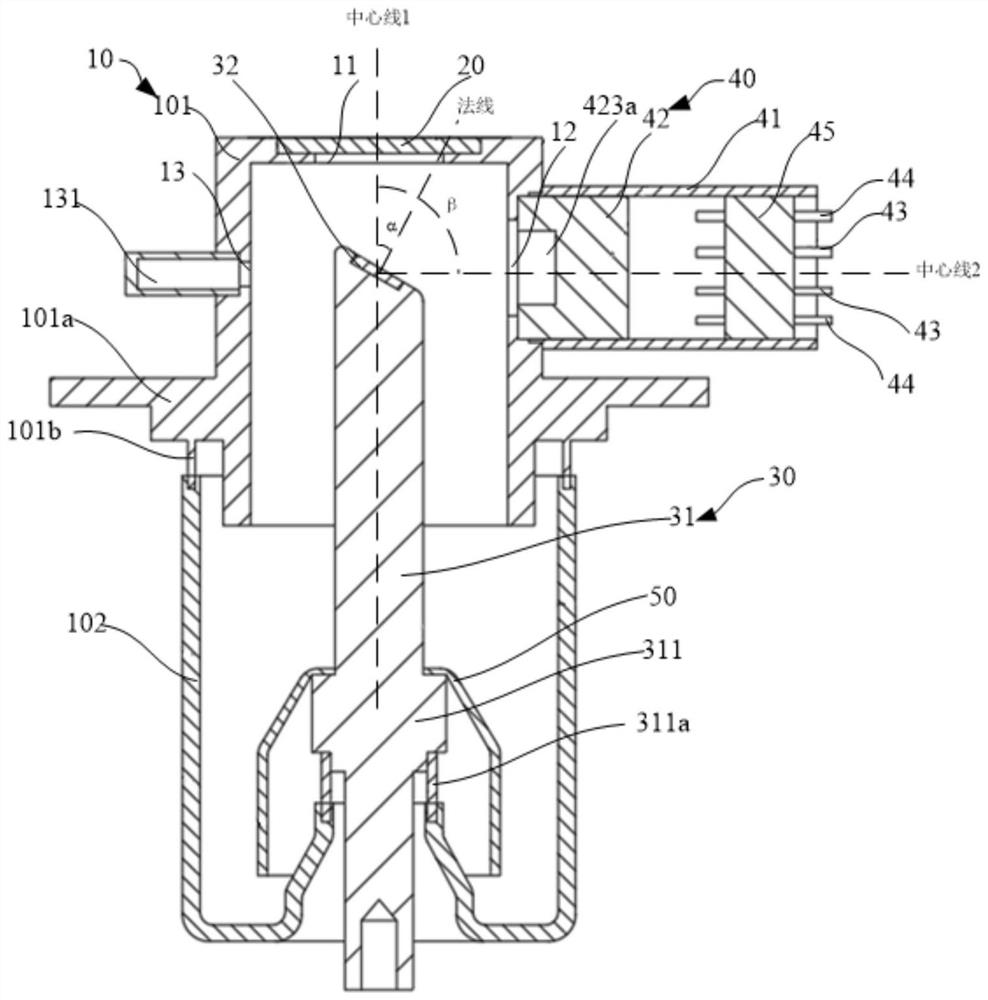

[0070] like figure 1 As shown, this embodiment provides a cold cathode X-ray tube, the cold cathode X-ray tube includes: a casing 10 , an exit window 20 , an anode assembly 30 and a cathode assembly 40 .

[0071] The housing 10 has a first installation opening 11 and a second installation opening 12 . The first installation opening 11 is provided on the top of the housing 10 , and the second installation opening 12 is provided at the top of the housing 10 . side wall.

[0072] In this embodiment, the housing 10 includes a first housing 101 and a second housing 102 , a first fixing portion 101 a is provided on the periphery of the first housing 101 , and a first fixing portion 101 a is provided below the fixing portion 101 a A connecting portion 101b, the first casing 101 is connected to the second casing 102 through the first connecting portion 101b. The material of the first casing 101 includes but is not limited to glass, ceramics, stainless steel, oxygen-free copper or mo...

Embodiment 2

[0092] like Image 6 As shown, this embodiment also provides a cold cathode X-ray tube, the cold cathode X-ray tube includes a casing 10 , an exit window 20 , an anode target 32 and a cathode assembly 40 .

[0093] The housing 10 has an installation opening 14 , the installation opening 14 is provided on the top of the housing 10 , and the exit window 20 is installed in the installation opening 14 .

[0094] In this embodiment, the casing 10 includes a first casing 101 and a second casing 102 . The first casing 101 is provided with a second fixing portion 101c at the periphery and a third connecting portion 101d at the bottom end of the first casing 101 . , the first casing 101 can be connected to an external device through the second fixing part 101c, and can be connected to the second casing 102 through the third connecting part 101d. The materials of the first casing 101 include but are not limited to glass, ceramics, stainless steel, oxygen-free copper and monel alloy; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com