High-sparking voltage boron series-free working electrolyte and preparation method thereof

A flash voltage and electrolyte technology, applied in the field of electrochemistry, can solve the problems of low flash voltage and short service life, and achieve high flash voltage, reliable quality and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

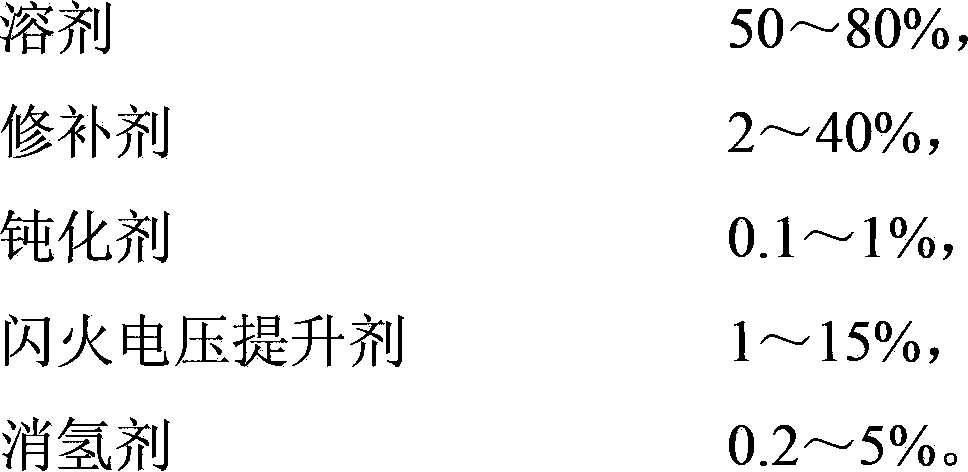

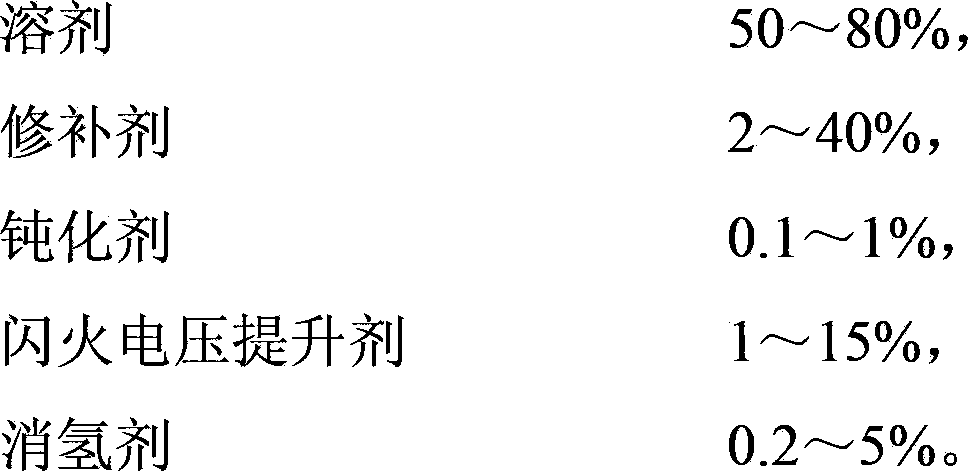

[0039] In the preparation method of the high flashover voltage boron-free working electrolyte of the present invention, comprise the following steps:

[0040] S1. Weighing: Weigh solvents, repairing agents, passivators, flash voltage boosters and hydrogen removers. The weighed weight components are consistent with the weight components in the electrolyte solution of the present invention.

[0041] Wherein, solvent is ethylene glycol;

[0042] The repair agent is organic ammonium carboxylate, and the organic ammonium carboxylate is ammonium adipate, ammonium suberate, ammonium hydrogen azelate, ammonium sebacate, ammonium dodecanoate, 1,7-ammonium sebacate, 1 , at least one of ammonium 6-dodecadedioate, ammonium 1,10-hexadecadioate, and ammonium 1,12-octadecadedioate;

[0043] The passivating agent is ammonium hypophosphite;

[0044] The flash voltage booster is at least one of diethylene glycol ether, polyethylene glycol ether, polyglyceryl ether, polymannitol ether, and poly...

Embodiment 1

[0050] Weigh in parts by weight: 50 parts of ethylene glycol, 40 parts of ammonium adipate, 0.6 parts of ammonium hypophosphite, 7.4 parts of diethylene glycol ether, and 2 parts of p-nitrobenzyl alcohol to prepare high flash voltage boron-free system working electrolyte.

[0051] Prepare high flash voltage boron-free working electrolyte with the above-mentioned weighed raw materials:

[0052] (1) Dissolving for the first time: Add ethylene glycol, ammonium adipate and diethylene glycol ether into the container, heat to 140°C, stir until completely dissolved; stop heating, continue stirring, and cool down to 110°C.

[0053] (2) Dissolving for the second time: add ammonium hypophosphite and p-nitrobenzyl alcohol in sequence to the solution cooled to 110°C in (1), and keep the temperature at 110°C for 50 minutes.

[0054] (3) Cooling: place and cool to room temperature, room temperature is 20°C, to obtain electrolyte.

Embodiment 2

[0056] Weigh by parts by weight: 80 parts of ethylene glycol, 10 parts of ammonium suberate, 0.1 part of ammonium hypophosphite, 9.7 parts of polyethylene glycol ether, 0.2 part of p-nitrobenzyl alcohol, to prepare high flash voltage boron-free Department of working electrolyte.

[0057] Prepare high flash voltage boron-free working electrolyte with the above-mentioned weighed raw materials:

[0058] (1) Dissolving for the first time: Add ethylene glycol, ammonium suberate and polyethylene glycol ether into the container, heat to 140°C, stir until completely dissolved; stop heating, continue stirring, and cool down to 110°C.

[0059] (2) Dissolving for the second time: add ammonium hypophosphite and p-nitrobenzyl alcohol in sequence to the solution in (1) cooled down to 110°C, and keep the temperature at 110°C for 70 minutes.

[0060] (3) Cooling: place and cool to room temperature, room temperature is 25°C, to obtain electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com