Method for preparing VOCs catalytic combustion catalyst

A catalytic combustion and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of low loading capacity, achieve large loading capacity, facilitate catalytic activity and stability, and evenly distribute Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

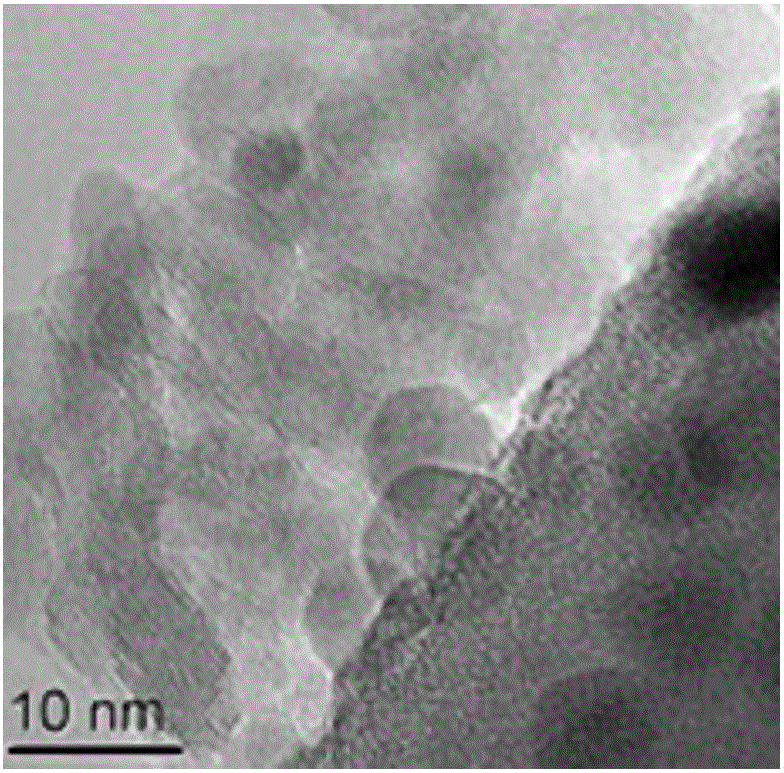

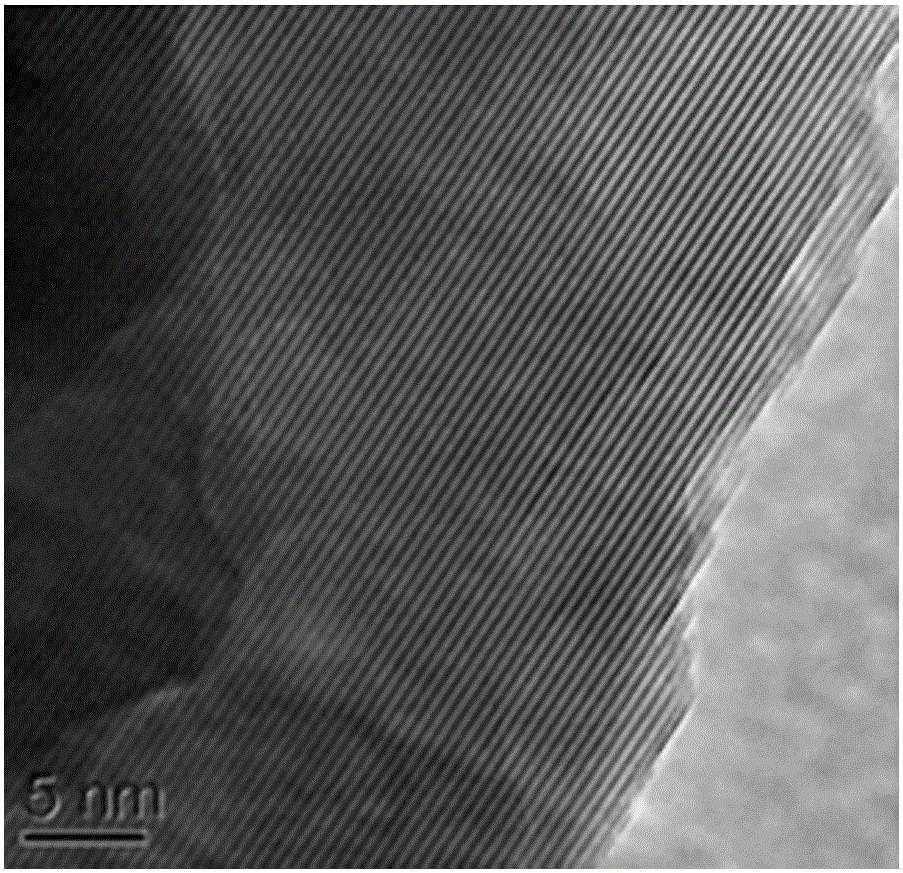

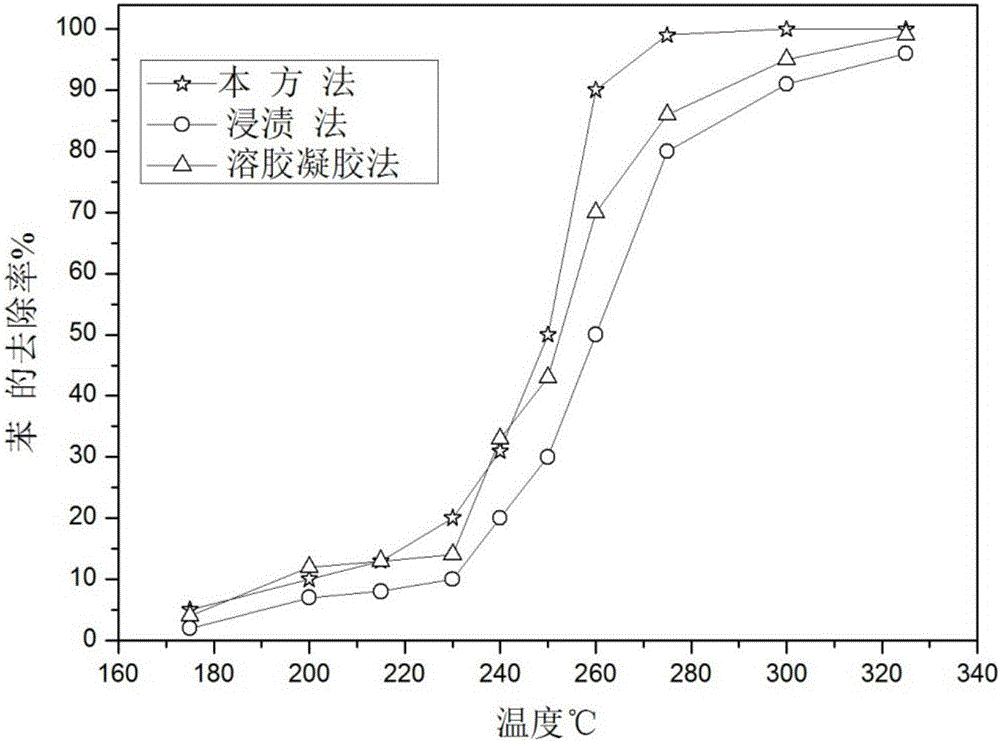

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing VOCs catalytic combustion catalyst, comprising the following steps:

[0022] ⑴ 2mmol Cu(CH 3 COO) 2 ·H 2 O was dissolved in 10 mL of distilled water, and solution A was obtained after stirring for 10 minutes. 1 mmol of terephthalic acid was dissolved in 10 mL of N,N-dimethylformamide, and solution B was obtained after stirring for 10 minutes. Add solution B to solution A with constant stirring.

[0023] (2) Put 2g of commercial cordierite carrier into the mixed solution, and heat in a water bath at 50°C for 4 hours. After standing for 10 hours, the material Cu-MOF / cordierite was formed.

[0024] (3) Add 5mmol Mn(NO 3 ) 2 Solution C was prepared by dissolving in 15 mL of distilled water. And (2) the prepared material was washed with N,N-dimethylformamide and distilled water, and then put into a drying oven to dry for 10 hours at 60°C. After drying, put into solution C for loading.

[0025] (4) aging the material prepared in step (3) for 1...

Embodiment 2

[0029] A method for preparing VOCs catalytic combustion catalyst, comprising the following steps:

[0030] ⑴ Add 1mmol Ni(NO 3 ) 2 ·6H 2 Solution A was obtained after O was dissolved in 10 mL of distilled water and stirred for 10 minutes. Dissolve 1 mmol of trimesic acid in 10 mL of N,N-dimethylformamide, and stir for 10 minutes to obtain solution B. Add solution B to solution A with constant stirring.

[0031] (2) Put 2g of commercial cordierite carrier into the mixed solution, and heat in a water bath at 50°C for 4 hours. After standing for 10 hours, the material Ni-MOF / cordierite was formed.

[0032] (3) Add 5mmol Mn(NO 3 ) 2 Sol C was prepared by dissolving in 15 mL of distilled water, adding 1 mmol of citric acid and heating in a water bath at 60°C for 3 hours. And (2) the prepared material was washed with ethanol and distilled water, and then put into a drying oven to dry for 10 hours at 60°C. After drying, put into sol C for loading.

[0033] (4) Aging the mat...

Embodiment 3

[0037] A method for preparing VOCs catalytic combustion catalyst, comprising the following steps:

[0038] ⑴ Add 1mmol Ni(NO 3 ) 2 ·6H 2 Solution A was obtained after O was dissolved in 10 mL of distilled water and stirred for 10 minutes. 1 mmol of 2-methylimidazole was dissolved in 10 mL of absolute ethanol, and solution B was obtained after stirring for 10 minutes. Add solution B to solution A with constant stirring.

[0039] (2) Take 2g commercial γ-Al 2 o 3 The carrier was put into the mixed solution, and heated in a water bath at 50° C. for 4 hours. After standing for 10 hours, the material Ni-MOF / cordierite was formed.

[0040] (3) Add 5mmol Ni(NO 3 ) 2 ·6H 2 Solution C was prepared by dissolving O in 15 mL of distilled water. And (2) the prepared material was washed with ethanol and distilled water, and then put into a drying oven to dry for 10 hours at 60°C. After drying, put into solution C for loading.

[0041] (4) Aging the material prepared in step (3) f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com