Energy storage battery detection method

A detection method and technology for energy storage batteries, which are applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problem of inability to detect the working performance of battery packs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

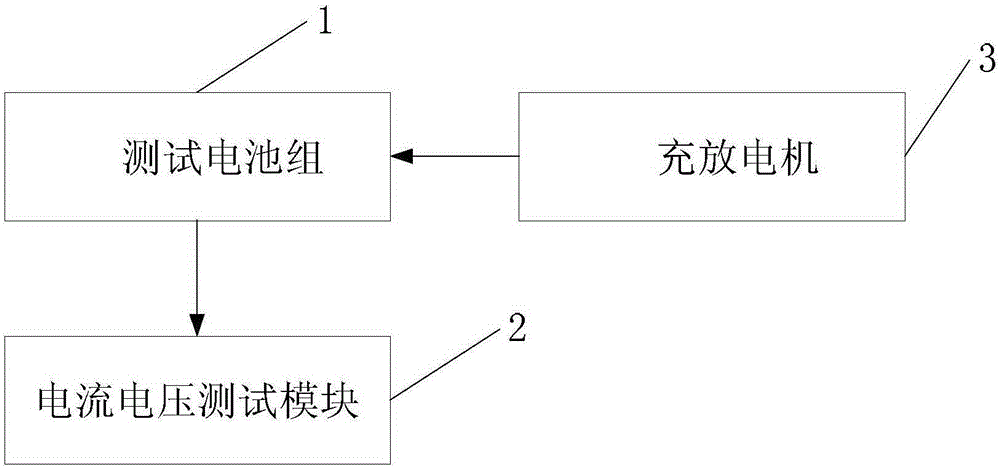

[0053] Specific implementation mode one: see Figure 1 to Figure 3 Describe this embodiment, an energy storage battery detection method described in this embodiment, the method is realized based on the test battery pack 1, the current and voltage test module 2 and the charging and discharging machine 3, and the test battery pack 1 is composed of a plurality of battery cells body composition; the method comprises the steps of:

[0054] Step 1, connect the test battery pack 1, the current and voltage test module 2 and the charging and discharging machine 3, so that the current and voltage testing module 2 is used to detect the voltage and current of the testing battery pack 1, and the charging and discharging machine 3 is used to test the battery pack 1 Perform current and voltage control. After the connection is completed, test battery pack 1 and rest for 5 minutes;

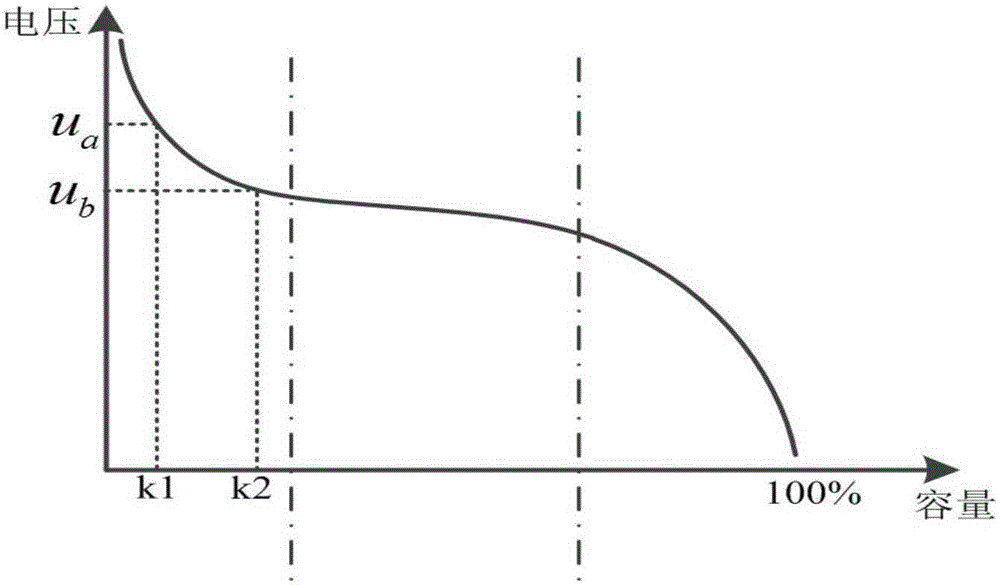

[0055] Step 2, the charging and discharging machine 3 discharges the test battery pack 1 with a constant curre...

specific Embodiment approach 2

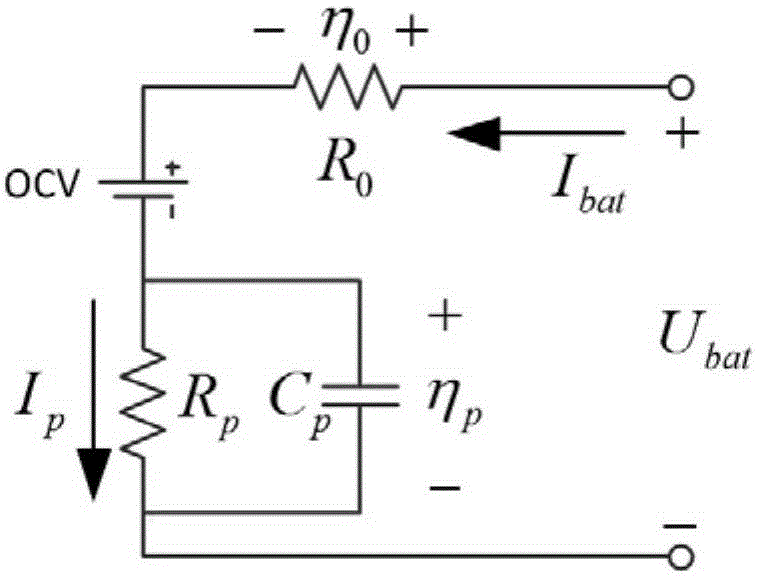

[0096] Specific implementation mode two: see Figure 1 to Figure 3 This embodiment is described. The difference between this embodiment and the energy storage battery detection method described in Embodiment 1 is that in step 12, the total power Power at each moment of testing the battery pack 1 is obtained. k The method is through the following formula:

[0097] power k =U bat,min (OCV k -U bat,min ) / R o,k (Formula 5),

[0098] Realized; among them, U bat,min Indicates the battery pack terminal voltage, and U bat,min =U' m,k , U' n,k , U′ p,k .

specific Embodiment approach 3

[0099] Specific implementation mode three: see Figure 1 to Figure 3 Describe this embodiment. The difference between this embodiment and the energy storage battery detection method described in the first embodiment is that in step 13, the power of each battery cell Power' at each time is obtained. k The method is through the following formula:

[0100] Power' k =U' bat,min (OCV' k -U' bat,min ) / R' i,k (Formula 6),

[0101] Realized; among them, U′ bat,min Indicates the battery cell terminal voltage, and U' bat,min =u' i,k 、u″ i,k , u″' i,k .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com