Application of carboxylation graphene oxide serving as adsorbent in metal ion adsorption

A graphene and adsorbent technology, applied in other chemical processes, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as unreported, and achieve easy availability of raw materials, simple preparation methods, and good performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

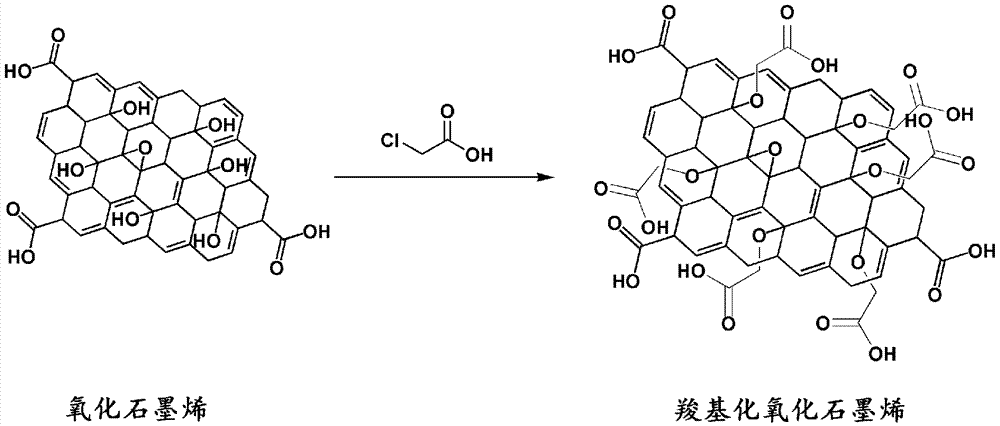

[0023] The specific steps of the preparation method of carboxylated graphene oxide material are as follows:

[0024] S1: Add graphene oxide to deionized water, and disperse to obtain an aqueous solution of graphene oxide; S2: Add sodium hydroxide and chloroacetic acid to the aqueous solution of graphene oxide, and stir at room temperature for 24 hours; S3: Wash with deionized water Several times, the carboxylated graphene oxide material was obtained after drying.

[0025] Step S1 specifically includes: ultrasonically dispersing in a 200W ultrasonic cleaner for 30 minutes to obtain an aqueous solution of graphene oxide; in addition, the concentration of graphene oxide is 1 mg / mL.

[0026] In step S2, the addition amount of each component is: graphene oxide: sodium hydroxide: chloroacetic acid: 50mg: 3g: 2g.

[0027] In step S3, the drying process is specifically to dry the product under vacuum at 60° C. for 12 hours.

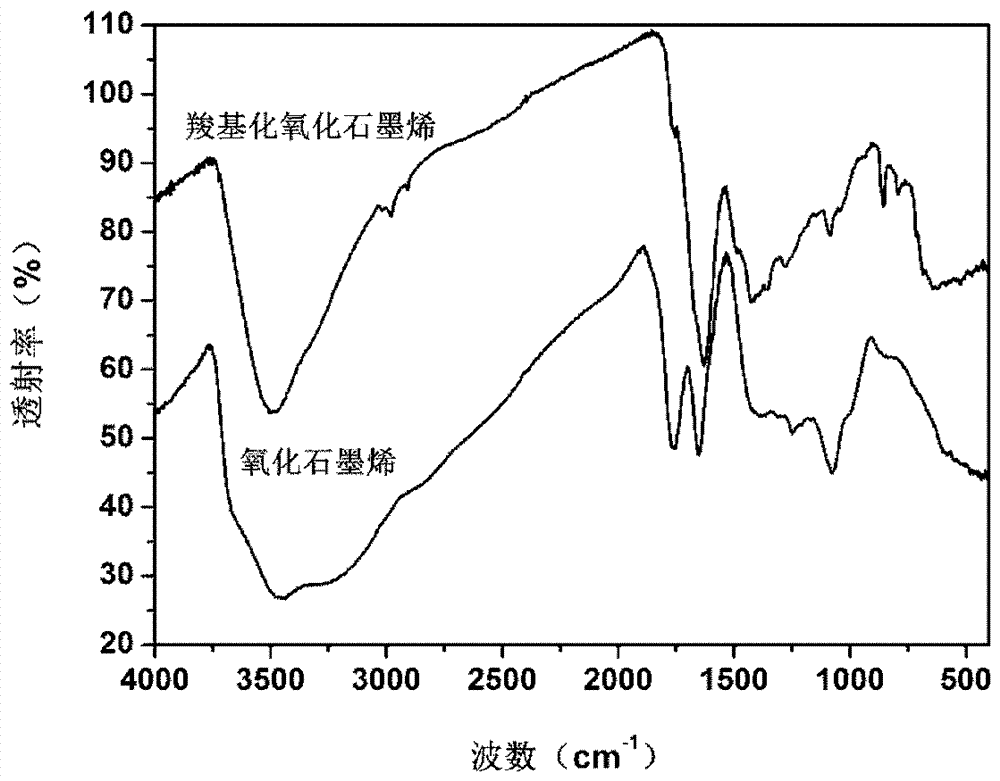

[0028] The structure of the carboxylated graphene oxide m...

Embodiment 2

[0033] Determination of Adsorption Ability of Carboxylated Graphene Oxide on Cu(Ⅱ) or Pb(Ⅱ) Metal Ions by Atomic Absorption Spectrophotometry

[0034] Accurately weigh 3 mg of carboxylated graphene oxide material and add it to 10 mL of pH=4.00, 1.5 mmol / L solution of Cu(II) or Pb(II) ions, stir at 25°C for 45 minutes, and use a 220 nm microporous filter to The membrane filter out the adsorbent to obtain a clarified solution, and then use an atomic absorption spectrophotometer to detect the metal ion content of the clarified solution, and calculate the content change of the metal ion content before and after treatment, so as to calculate the effect of carboxylated graphene oxide on divalent metal ions the amount of adsorption. At the same time, using unmodified graphene oxide as a comparative example, the same method was used to treat the same industrial wastewater.

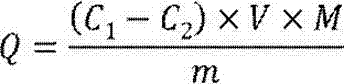

[0035] The adsorption amount of carboxylated graphene oxide to metal ions is calculated according to the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com