Mineral processing tailing wastewater treatment method

A treatment method and wastewater technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor removal capacity of heavy metal ions, poor compressibility of polymers, and water quality problems To achieve the effect of shortening the coagulation time, reducing the content of heavy metal ions, and accelerating the sedimentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

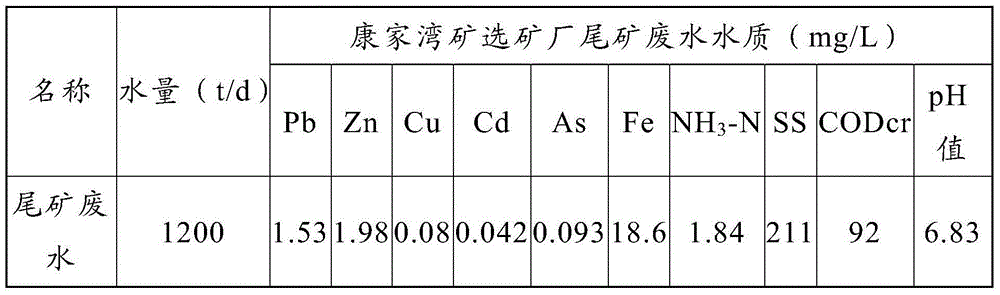

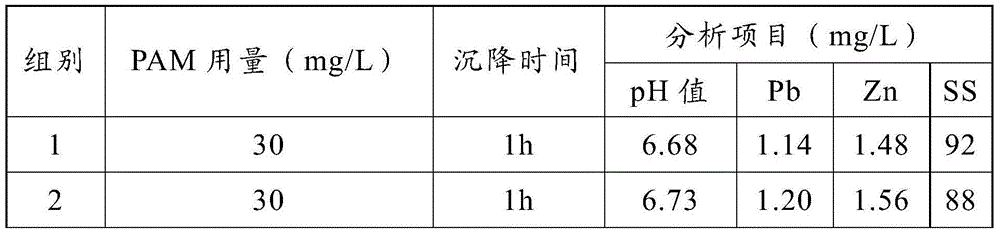

[0035] Add 800g of milk of lime to 1000ml of Kangjiawan mine dressing plant tailings wastewater to make the pH value of the tailings wastewater 8.2 to obtain destabilized wastewater. The composition of the tailings wastewater is shown in Table 1; 0.2wt% polyacrylamide aqueous solution, the amount of polyacrylamide added is 10mg / L, after 30 minutes of sedimentation, 400ml of tailings wastewater supernatant and flocs are obtained, and 10wt% polymeric sulfuric acid is added to the tailings wastewater supernatant For the aqueous iron solution, the amount of polyferric sulfate added is 10 mg / L, and purified water and flocs are obtained after settling for 30 minutes. The composition of the purified water was tested, and the test results were: pH value 8.26, Pb 0.28mg / L, Zn 0.18mg / L, SS 62mg / L, in line with the national wastewater comprehensive discharge standard GB25466-2010 first-level standard.

Embodiment 2

[0037] Add 1400g of milk of lime to 2000ml of Kangjiawan mine dressing plant tailings wastewater to make the pH value of the tailings wastewater 8.2 to obtain destabilized wastewater. The composition of the tailings wastewater is shown in Table 1; 0.5wt% polyacrylamide, the amount of polyacrylamide added is 10mg / L, after 30 minutes of sedimentation, 800ml of tailings wastewater supernatant and flocs are obtained, and a concentration of 15wt% polyacrylamide is added to the tailings wastewater supernatant Ferric sulfate aqueous solution, the addition amount of polyferric sulfate is 10mg / L, after settling for 30min, purified water and flocs are obtained. The composition of the purified water was tested, and the test results were: pH value 8.22, Pb 0.24mg / L, Zn 0.12mg / L, SS 58mg / L, in line with the national wastewater comprehensive discharge standard GB25466-2010 first-level standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com