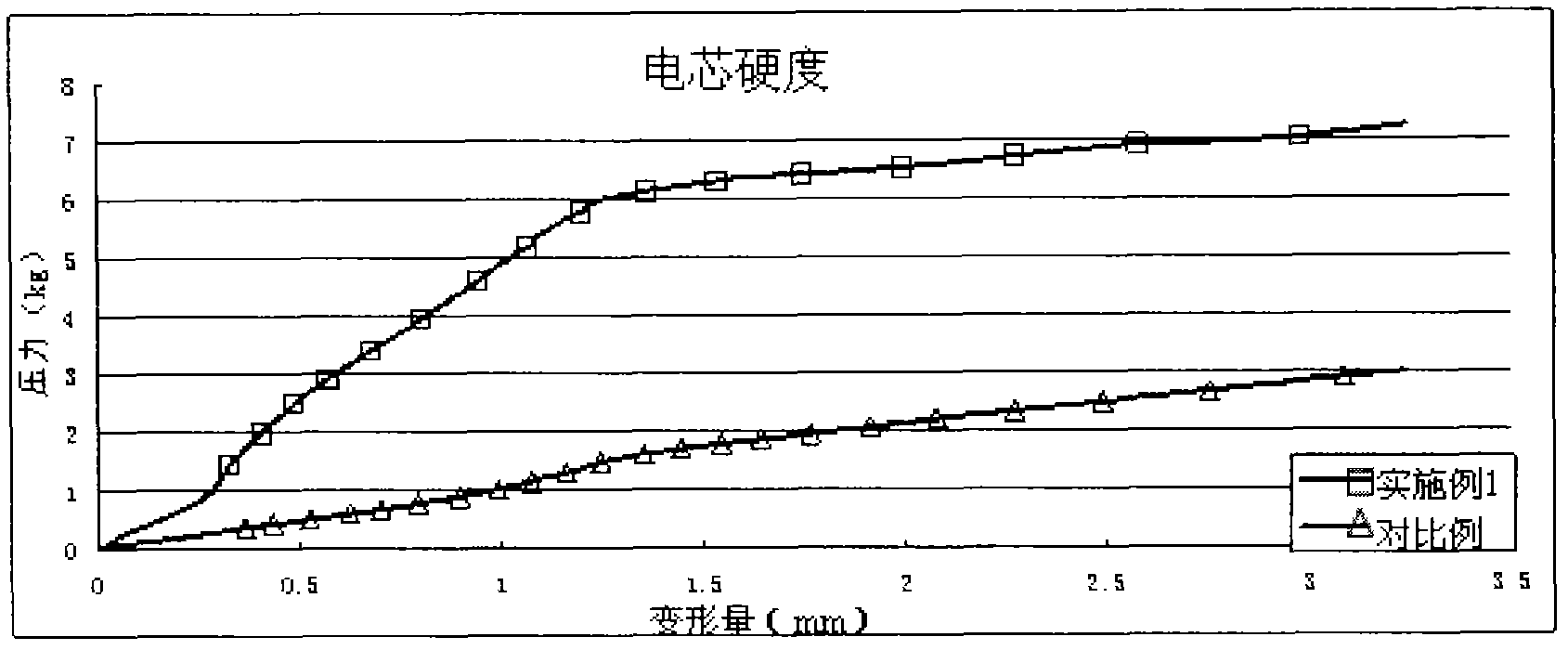

Method for improving hardness of lithium ion cell

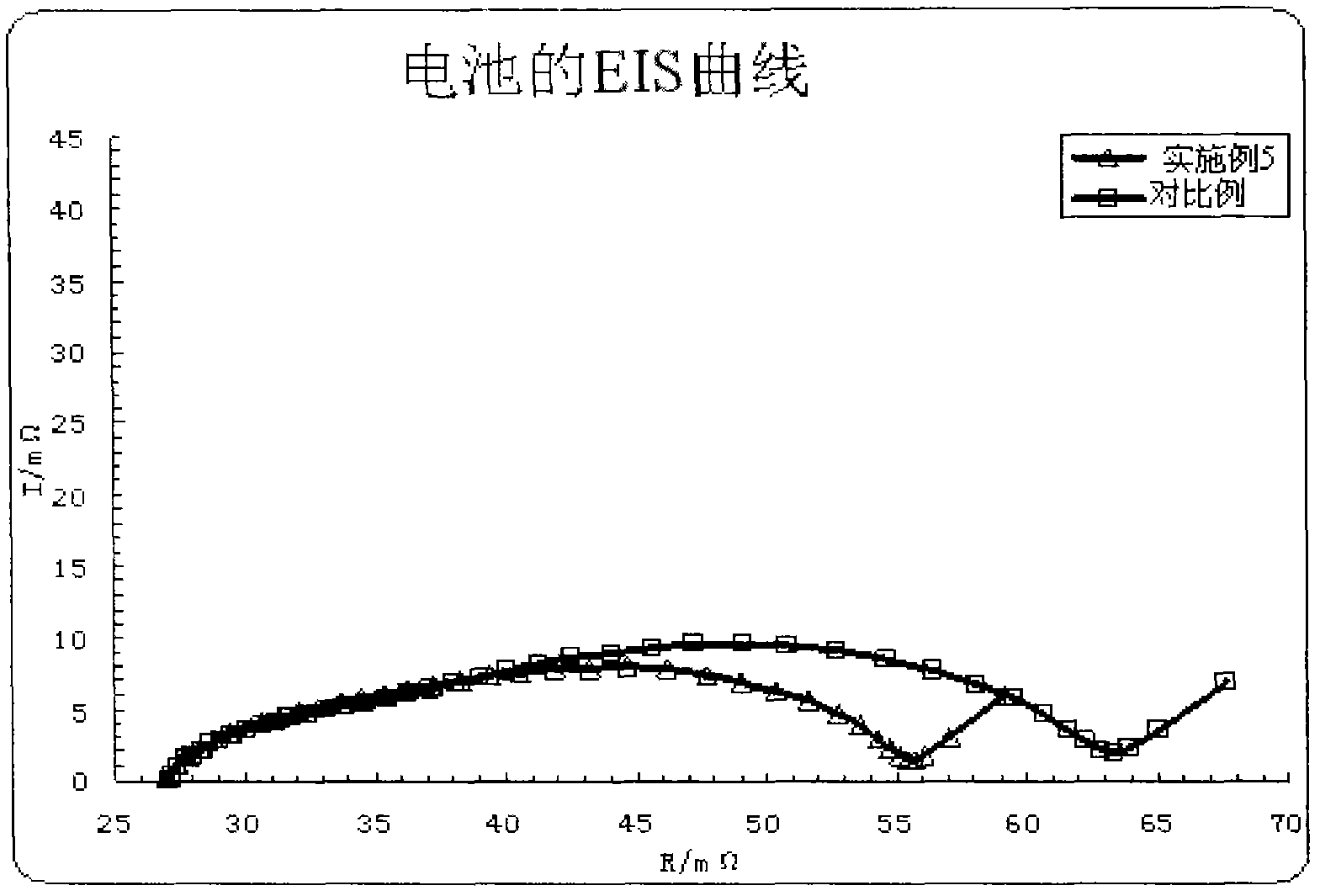

A lithium-ion battery, hardness technology, applied in the field of lithium-ion batteries, can solve the problems of lithium-ion battery electrochemical performance deterioration, battery capacity loss, increase the hardness of the battery core, etc., to achieve increased hardness, improved charge and discharge efficiency, and improved formation speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of the cathode sheet: spinel lithium manganese oxide (LiMnO 2 ), the conductive agent acetylene black and the binder polyvinylidene fluoride (PVDF) are added to the solvent nitrogen-methylpyrrolidone (NMP) according to the mass ratio of 94:3:3, and stirred and dispersed using a high-speed mixer to form a uniform positive electrode slurry. This slurry is coated on the aluminum foil current collector, and the solvent is dried. After drying, the positive electrode coating weight per unit area is 20.13mg / cm 2 , and then compact the pole piece, the density of the coating after compaction is about 3.0g / cm 3 .

[0037] Preparation of the anode sheet: the negative electrode active material artificial graphite, conductive agent acetylene black, binder styrene-butadiene rubber (SBR, emulsion, about 50% solid content, 2.5 is the weight ratio of dry matter) and thickener carboxymethyl fiber Add plain sodium (CMC) into the solvent water at a mass ratio of 94.5:1.5:2:2...

Embodiment 2

[0045] Different from Example 1 is the preparation of lithium ion battery:

[0046]Step 1: Assemble the cathode sheet, anode sheet, and diaphragm into a battery cell through the lamination process, then put the battery cell into a packaging bag, inject the electrolyte solution after baking, and let it stand still. Batteries;

[0047] Step 2, place the fully soaked cells to be formed in the formation fixture, apply pressure to the surface of the cells through the fixture, the pressure is 0.1 MPa, and then pre-bake the cells at a temperature of 120°C for 1 min;

[0048] Step 3: Place the pre-baked formation jig that is to be formed into a battery cell first in the formation machine for formation, the formation temperature is 25°C, the formation current is 0.02C ("C" is the theoretical capacity of the battery cell), and the formation time is After 10 minutes, the formation cut-off potential was 3.0V. Then put it in the charge-discharge test machine to perform charge / discharge a...

Embodiment 3

[0052] Different from Example 1 is the preparation of lithium ion battery:

[0053] Step 1: Assemble the cathode sheet, anode sheet, and diaphragm into a battery cell through the lamination process, then put the battery cell into a packaging bag, inject the electrolyte solution after baking, and let it stand still. Batteries;

[0054] Step 2, place the fully soaked cells to be formed in the formation fixture, apply pressure to the surface of the cells through the fixture, the pressure is 2.0 MPa, and then pre-bake the cells at a temperature of 30°C for 100 minutes;

[0055] Step 3: Place the pre-baked formation jig to be formed in the formation machine first, the formation temperature is 100°C, the formation current is 0.02C ("C" is the theoretical capacity of the battery), and the formation time is After 10 minutes, the formation cut-off potential was 3.0V. Then put it in the charge-discharge test machine to perform charge / discharge and discharge / charge operations in sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com