Scratch-proof float glass conveying device

A float glass and transportation device technology, applied in glass transportation equipment, glass production, glass manufacturing equipment and other directions, can solve the problems of scratching and deformation of glass ribbon, slow gas rising speed, and late formation, etc., and achieves simple structure and improved utilization. rate, the effect of preventing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

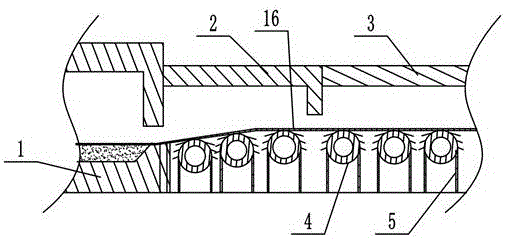

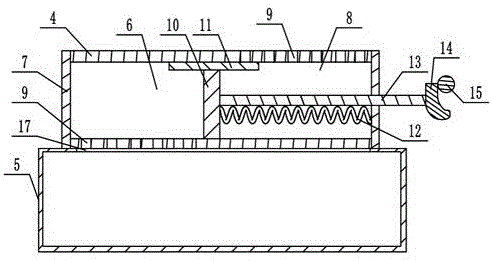

[0029] The reference signs in the accompanying drawings of the description include: tin bath part 1, transition roller table 2, annealing kiln 3, conveying roller 4, gas supply box 5, first compression chamber 6, sealing plate 7, second compression chamber 8, air hole 9. Piston plate 10, inner boss 11, spring 12, connecting rod 13, cam 14, ejector rod 15, float glass 16, supply port 17.

[0030] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0031]The scratch-resistant float glass 16 transportation device is mainly composed of transition roller table 2 and annealing kiln 3, which are installed in turn on the right side of tin bath part 1, transition roller table 2 and annealing kiln Several transmission rollers 4 are all installed in the 3, and the transmission rollers 4 are rotatably connected on the frame. The conveying roller 4 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com