High-specific-capacity metal organic negative electrode material of secondary ion battery and preparation method thereof

A secondary ion, metal-organic technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of low mass specific capacity, poor Coulomb efficiency and electrochemical cycle performance, and achieve a simple synthesis method and stable electrochemical performance. The effect of cycle performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

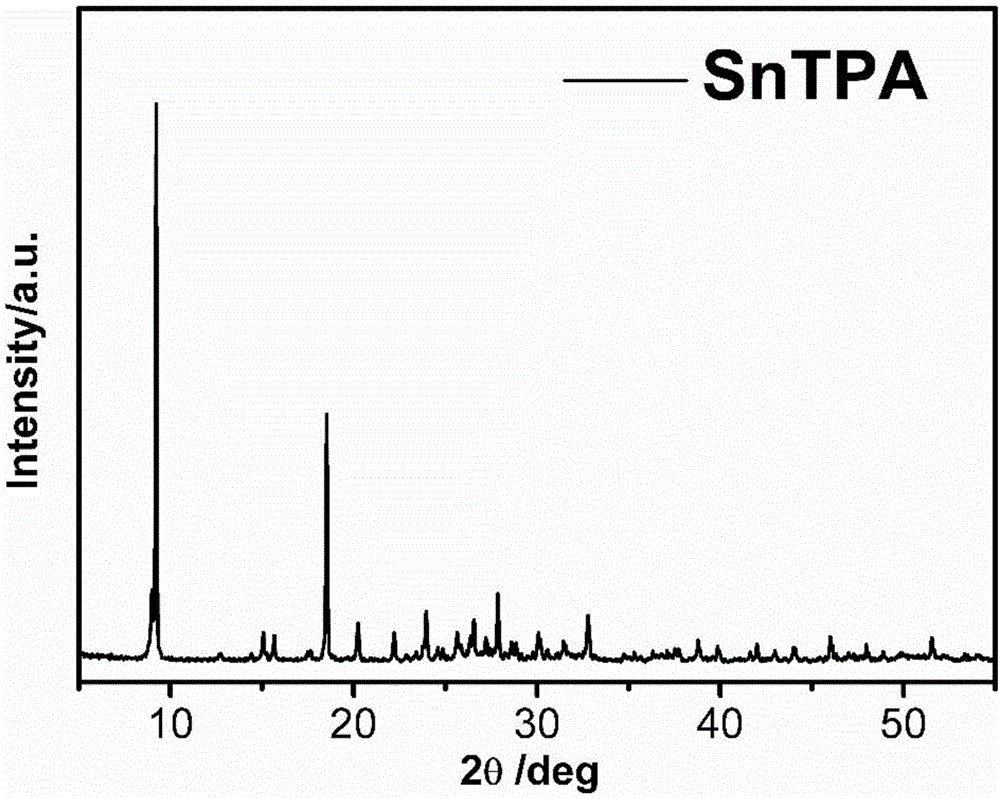

[0030] A metal-organic negative electrode material for a high specific capacity secondary ion battery, the preparation method comprising the following steps:

[0031] (1) Weigh 1.66 g of terephthalic acid with a purity of 99%, 0.85 g of analytically pure LiOH·H 2 O and 2.14gSnSO 4 , mixed, and then added to a beaker containing 40 mL of absolute ethanol, and ultrasonically stirred for 1 h;

[0032] (2) transferring the reaction solution obtained in step (1) into a polytetrafluoroethylene liner, and sealing it in a reaction kettle, and placing it at 110° C. to react for 12 hours to obtain a mixed solution containing light green stannous terephthalate precipitation;

[0033] (3) The mixed solution obtained in step (2) was washed 3-4 times with deionized water and absolute ethanol respectively, and then centrifuged, and the solid obtained by centrifugation was placed in a constant temperature drying oven at 80 ° C to dry for 6 hours, and ground to obtain light green Tin terephth...

Embodiment 2

[0038] A metal-organic negative electrode material for a high specific capacity secondary ion battery, the preparation method comprising the following steps:

[0039] (1) Weigh 0.83g of 99% pure phthalic acid, 0.43g of analytically pure LiOH·H 2 O and 1.07gSnSO 4 , mixed, and then added to a beaker containing 40 mL of absolute ethanol, and ultrasonically stirred for 1 h;

[0040] (2) transferring the reaction solution obtained in step (1) into a polytetrafluoroethylene liner, and sealing it in a reaction kettle, and placing it at 110° C. to react for 12h to obtain a mixed solution containing light yellow stannous phthalate precipitation;

[0041] (3) The mixed solution obtained in step (2) was washed 3-4 times with deionized water and absolute ethanol, respectively, and then centrifuged, and the solid obtained by centrifugation was placed in a constant temperature drying oven at 80 ° C to dry for 6 hours, and ground to obtain light yellow Stannous phthalate (Sn(1,2-bdc)).

[...

Embodiment 3

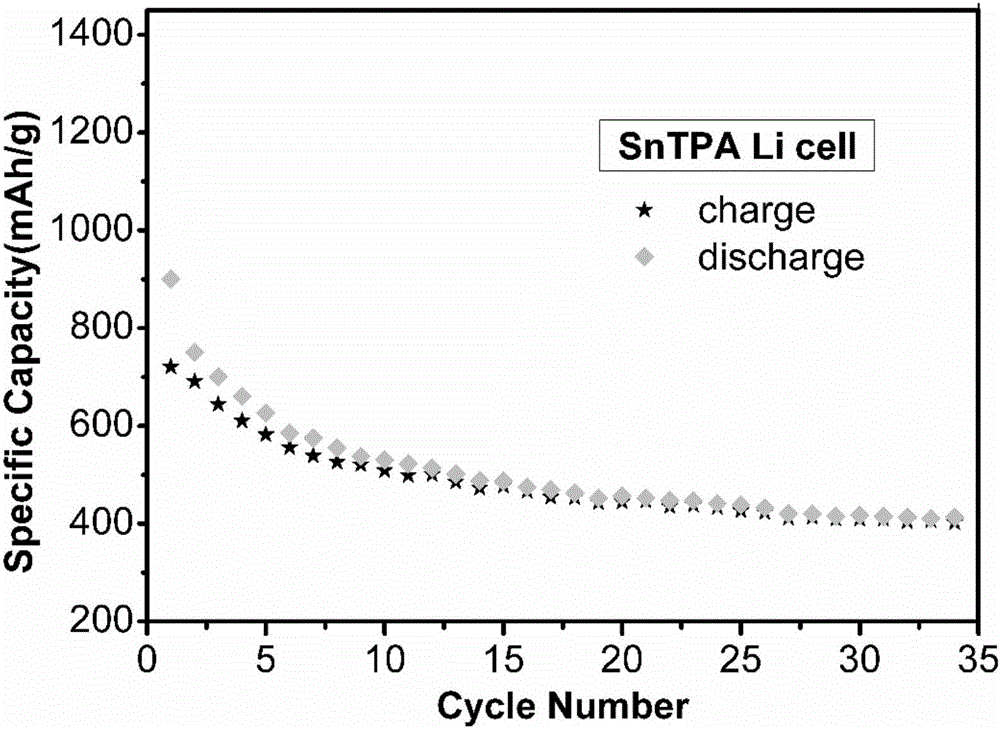

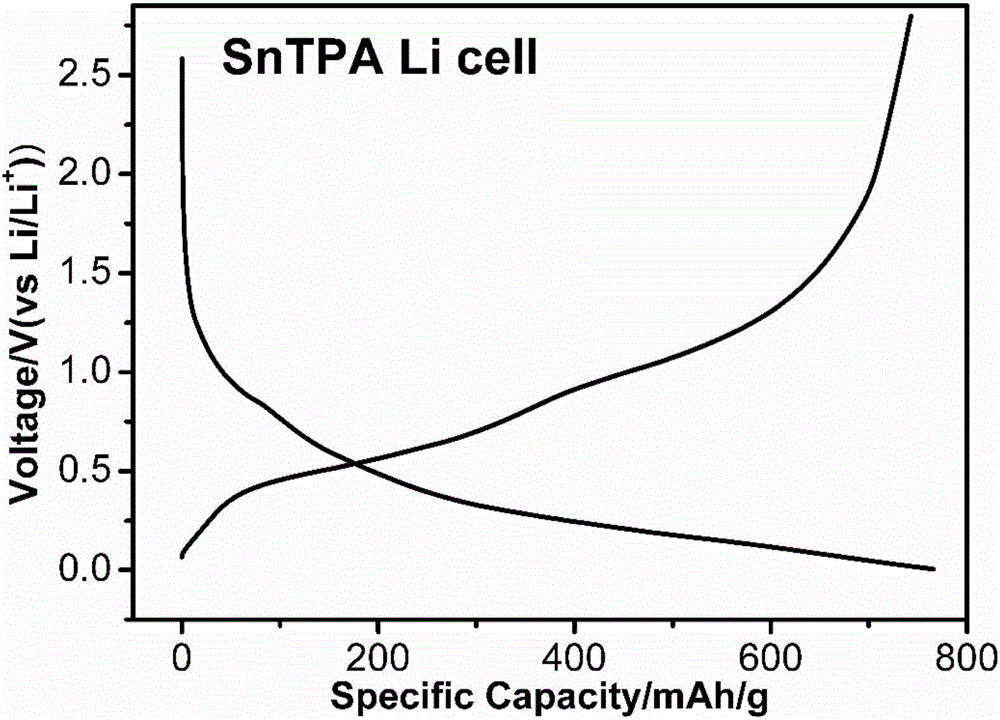

[0046] Using the stannous terephthalate prepared in Example 1 as a negative electrode material to assemble a sodium ion battery, the steps are as follows: an electrode sheet is made of stannous terephthalate, which is used as a negative electrode material for the sodium ion battery, and half-cell assembly is performed, The mass ratio of active material, acetylene black and PVDF (solvent is N-methylpyrrolidone) is 6:3:1, metal lithium is the counter electrode, glass fiber membrane is the diaphragm, and the electrolyte is 1mol / L NaPF 6 Dissolved in a mixed solution of EC (ethylene carbonate), DMC (dimethyl carbonate) and FEC (fluoroethylene carbonate) in a volume ratio of 1:1:1, the assembled battery was tested for cycle performance, and the current The density is 60mA / g, see the test results Figure 7 .

[0047] Depend on Figure 7 It can be seen that the discharge specific capacity in the first week is 548.9mAh / g, the charging mass specific capacity is 397.9mAh / g, the chargi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com