Trimethoxysilane-terminated polymer adhesive as well as preparation method and application thereof

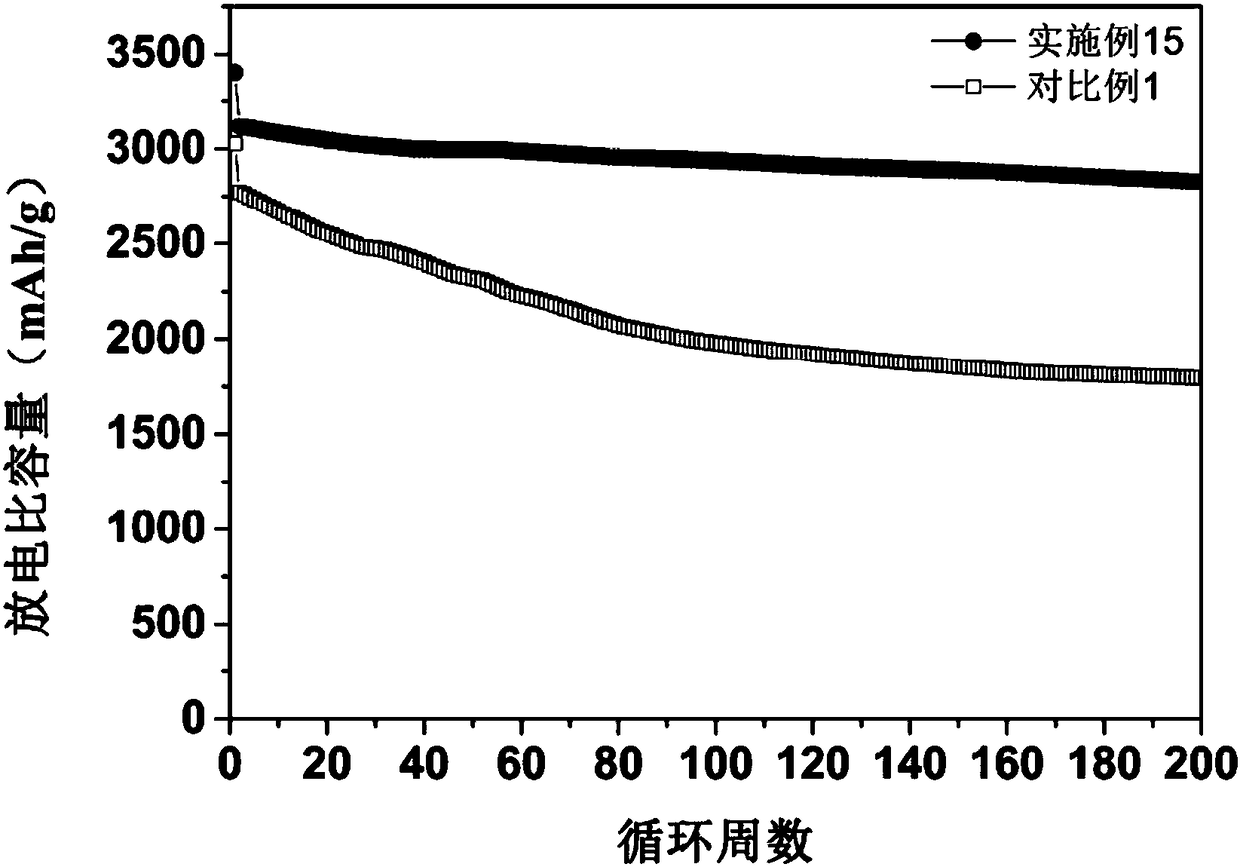

A technology of terminal siloxane group and polymer, which is applied in the field of siloxane group-terminated polymer adhesive and its preparation, and can solve the problems of limited adhesive force and mechanical strength, reduced capacity, low adhesive viscosity, etc. , to achieve the effect of improving cycle stability, alleviating capacity decay, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of the silicone-terminated polymer adhesive of the present embodiment comprises the following steps:

[0047] First mix 0.01 mol of polyethylene glycol (PEG, Mw=2000), 0.02 mol of 2,4-toluene diisocyanate (TDI) and dibutyltin dilaurate (DBTL), and dissolve in dimethylformamide . Then keep the temperature at 70° C. for 6 hours, and pass nitrogen protection. Then, 0.01 mol of 1,4-butanediol (BDO) was added for chain extension, and the temperature was kept at 70° C. for 6 hours to obtain a polyurethane solution. Among them, the mass of dibutyltin dilaurate is 0.3% of the total mass of polyethylene glycol, 2,4-toluene diisocyanate and 1,4-butanediol; polyethylene glycol, 2,4-toluene diisocyanate and 1, The mass ratio of the total mass of 4-butanediol to dimethylformamide is 1:1. Wherein, the mass of dibutyltin dilaurate (DBTL) is 0.3% of the whole reaction system. The mass ratio of the total mass of diol, diisocyanate and small molecule chain exte...

Embodiment 2

[0051] The specific preparation method of the siloxane-terminated polymer adhesive of this embodiment is the same as the preparation of A1, the difference is that the quality of silane coupling agent 3-aminopropyltriethoxysilane (KH550) and polyurethane The ratio was 0.2:1, and the resulting adhesive was designated as A2.

[0052] Adhesive A2 was used to assemble a lithium-ion battery according to the method described above.

Embodiment 3

[0054] The specific preparation method of the siloxane-terminated polymer adhesive of this embodiment is the same as the preparation of A1, the difference is that the quality of silane coupling agent 3-aminopropyltriethoxysilane (KH550) and polyurethane The ratio was 0.5:1 and the resulting adhesive was designated as A3.

[0055] Adhesive A3 was used to assemble a lithium-ion battery according to the method described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com