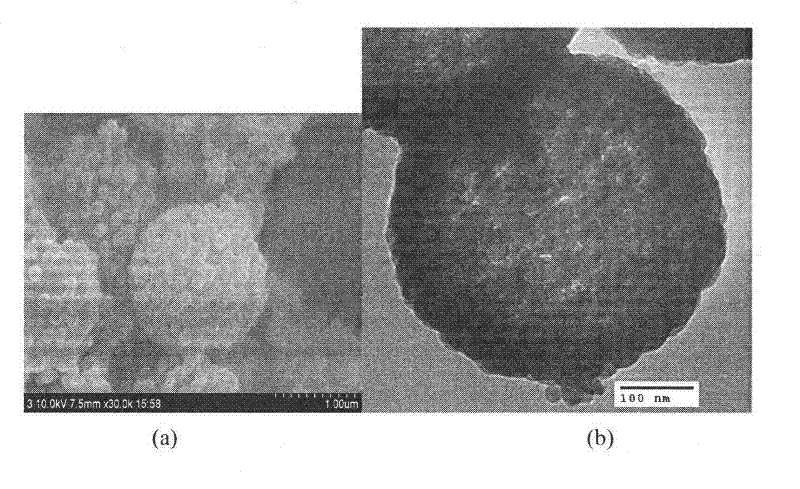

Macroporous/mesoporous hollow silica microballoon and its preparation method

A technology of silica and microspheres, applied in the direction of silica, silica, etc., can solve the problem of small mesopores, achieve the effects of controllable pore size, wide application range, and uniform distribution of small pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of Poly(EGDMA-co-VPy) core microspheres

[0033] Disperse 1.0mL of 4-vinylpyridine (VPy), 1.0mL of ethylene glycol dimethacrylate (EGDMA), and 0.04g of azobisisobutyronitrile (AIBN) in 80mL of acetonitrile, and put them into a clean 100mL two-necked bottle In the middle, install the fractionating column, the condenser and the receiving bottle, and add the zeolite. Use a 100mL electric heating mantle to heat at a voltage of 75V, control it to rise from room temperature to boiling within 30 minutes, and start to distill off the solvent acetonitrile; control it to evaporate 40mL of acetonitrile within 1.5 hours and stop the reaction. The obtained polymer microspheres were suction-filtered with a G-5 sandglass, washed with ethanol three times, soaked for half an hour each time, and dried in a vacuum oven at 40°C to constant weight. The particle size of the obtained Poly(EGDMA-co-VPy) microspheres was 1.513 μm.

[0034] 2. Preparation of PolyAA crown microsp...

Embodiment 2

[0041] 1. Preparation of Poly(EGDMA-co-VPy) core microspheres

[0042] Disperse 1.2mL of 4-vinylpyridine (VPy), 0.8mL of ethylene glycol dimethacrylate (EGDMA), and 0.04g of azobisisobutyronitrile (AIBN) in 80mL of acetonitrile, and put them into a clean 100mL two-necked bottle In the middle, install the fractionating column, the condenser and the receiving bottle, and add the zeolite. Use a 100mL electric heating mantle to heat at a voltage of 75V, control it to rise from room temperature to boiling within 30 minutes, and start to distill off the solvent acetonitrile; control it to evaporate 40mL of acetonitrile within 1.5 hours and stop the reaction. The obtained polymer microspheres were suction-filtered with a G-5 sandglass, washed with ethanol three times, soaked for half an hour each time, and dried in a vacuum oven at 40°C to constant weight. The particle size of the obtained Poly(EGDMA-co-VPy) microspheres was 3.08 μm.

[0043] 2. Preparation of PolyAA crown microsph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com