Preparation method of anodized aluminum film of through hole

An anodized aluminum and anodic oxidation technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of large emissions, high cost, complex equipment, etc., and achieve safe operation, uniform cycle, and simplified equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Make high-purity aluminum flakes into specific shapes, anneal in argon atmosphere, and then wash them in strong alkali solution, organic solvent and deionized water to obtain clean aluminum flakes;

[0035] (2) With the clean aluminum sheet obtained in step (1) as the anode and the ordinary aluminum sheet as the cathode, the HClO at 0°C 4 : CH 3 CH 2 In the polishing solution of OH=1:4, 15V DC constant voltage electrochemical polishing for 3min, the anode gets polished aluminum sheet;

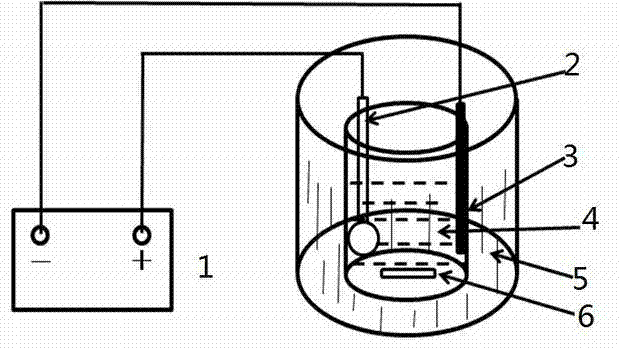

[0036] (3) Use the polished aluminum sheet obtained in step (2) as the anode, the graphite electrode as the cathode, and 0.3mol / L oxalic acid as the electrolyte, and conduct an anodic oxidation at 0°C for 6 hours at a DC constant voltage;

[0037] (4) Place the anodized aluminum sheet obtained in step (3) in 1.8%CrO at 60°C 3 and 6%H 3 PO 4 Soak in the mixed aqueous solution for 6 hours, then wash with deionized water;

[0038] (5) Use the aluminum sheet cleaned with deionized ...

Embodiment 2

[0044] (1) Make high-purity aluminum flakes into specific shapes, anneal in argon atmosphere, and then wash them in strong alkali solution, organic solvent and deionized water to obtain clean aluminum flakes;

[0045] (2) With the clean aluminum sheet obtained in step (1) as the anode and the ordinary aluminum sheet as the cathode, the HClO at 0°C 4 : CH 3 CH 2 In the polishing solution of OH=1:5, 10V DC constant voltage electrochemical polishing for 5min, the anode gets polished aluminum sheet;

[0046] (3) Use the polished aluminum sheet obtained in step (2) as the anode, the graphite electrode as the cathode, and 0.5mol / L oxalic acid as the electrolyte, and conduct an anodic oxidation once at a DC constant voltage of 10°C for 6 hours;

[0047] (4) Place the anodized aluminum sheet obtained in step (3) at 80°C in 3%CrO 3 and 10%H 3 PO 4 Soak in the mixed aqueous solution for 6 hours, then wash with deionized water;

[0048] (5) Use the aluminum sheet cleaned with deioniz...

Embodiment 3

[0052] (1) Make high-purity aluminum flakes into specific shapes, anneal in argon atmosphere, and then wash them in strong alkali solution, organic solvent and deionized water to obtain clean aluminum flakes;

[0053] (2) With the clean aluminum sheet obtained in step (1) as the anode and the ordinary aluminum sheet as the cathode, the HClO at 0°C 4 : CH 3 CH 2 In the polishing solution of OH=1:10, 21V DC constant voltage electrochemical polishing for 3min, the anode was polished aluminum sheet;

[0054] (3) With the polished aluminum sheet obtained in step (2) as the anode and the graphite electrode as the cathode, 0.6mol / L H 3 PO 4 As the electrolyte, an anodic oxidation is performed once at 20°C for 8 hours at a DC constant voltage;

[0055] (4) Place the anodized aluminum sheet obtained in step (3) at 90°C in 5%CrO 3 and 15%H 3 PO 4 Soak in the mixed aqueous solution for 6 hours, then wash with deionized water;

[0056] (5) Use the aluminum sheet washed with deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com