Preparation and use of pore diameter controllable mesoporous silicon dioxide microsphere

A technology of mesoporous silica and silica gel microspheres, which is applied in the direction of silica, silica, etc., can solve problems such as application limitations, and achieve the effect of uniform particle size and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Step (1) Add 10g of polyether amine with an average molecular weight of 4000, 1.1g of epichlorohydrin, and 25g of absolute ethanol in a 50ml round bottom flask, stir at room temperature for 12 to 24 hours, evaporate the solvent and excess Reactant.

[0044] Step (2) Dissolve the product obtained in step 1 in 25g of absolute ethanol, add 0.70g of trimethylamine alcohol solution, react at 80-85°C for 12-24 hours, evaporate the solvent under reduced pressure, and obtain a colorless or light yellow viscous The thick product is the new four-headed quaternary ammonium salt cationic surfactant 1.

Embodiment 2

[0046] In embodiment 1 step (1), the polyetheramine that 10g average molecular weight is 4000 is replaced by the polyetheramine that average molecular weight is 2000, and 1.1g epichlorohydrin is replaced by 0.55g epichlorohydrin, in embodiment 1 In step (2), the 0.70g trimethylammonium alcohol solution is replaced by 0.35g trimethylammonium alcohol solution, and other steps are all operated according to Example 1, and the obtained colorless or light yellow sticky substance is the surface of the new four-headed quaternary ammonium salt cation. active agent 2.

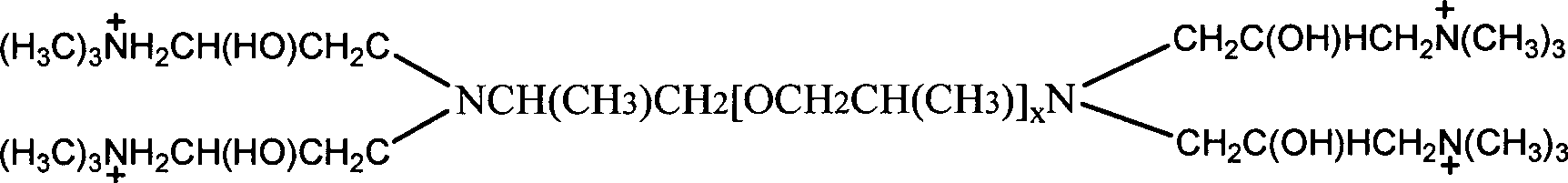

[0047] figure 1 It is a schematic diagram of the chemical structure of novel four-headed quaternary ammonium salt cationic surfactants 1 and 2.

[0048] (2) Preparation of mesoporous silica microspheres

Embodiment 3

[0050] Step (1) Add 0.50g of surfactant 1, 32g of anhydrous methanol, and 40g of deionized water into a 100ml round bottom flask and stir at 35°C for 20 minutes. After the solution is transparent, add 0.05ml of ammonia and 2.5g of normal Methyl silicate, stop stirring after the solution is turbid, let it stand for 3 hours, filter, wash with anhydrous methanol for 2 to 4 times, and dry at room temperature.

[0051] Step (2) Add 1 g of the obtained solid to 50 ml of deionized water, place it in an autoclave lined with polytetrafluoroethylene, let it stand at 55 ° C for 24 hours, filter it after cooling, and wash it with deionized water for 2 to 3 times , dried at room temperature, and then placed in a muffle furnace at 30-500°C for 2 hours, and then calcined at 500°C for 4 hours to obtain a white powder.

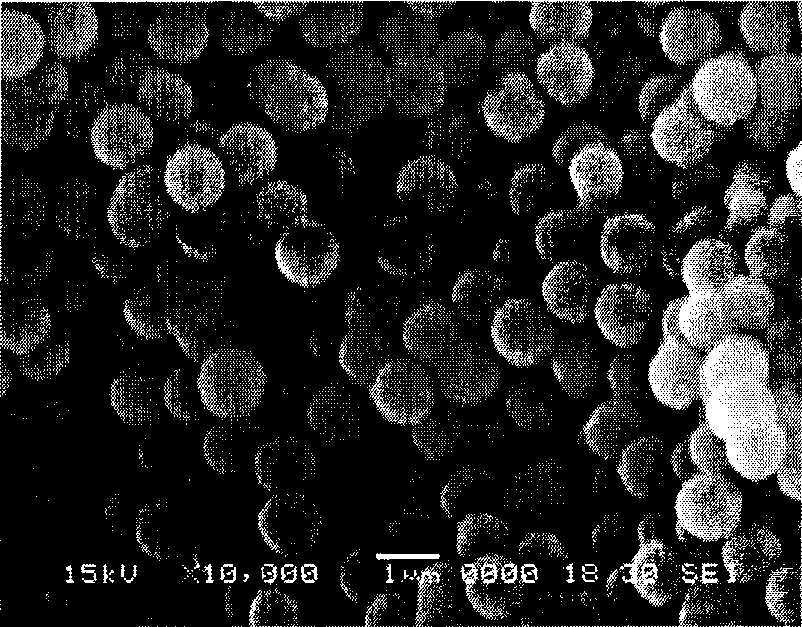

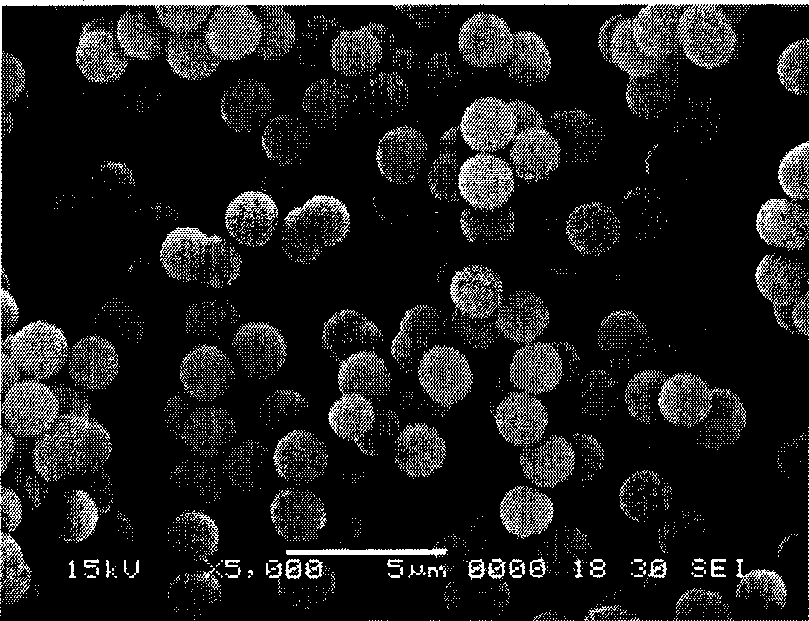

[0052] After scanning electron microscope analysis, the measured particle size is 1 μm. Use N 2 The adsorption and desorption instrument was used for analysis, and the avera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com