Resistivity-controllable conductive silicon carbide foam ceramic material and its preparing process

A technology of foamed ceramics and silicon carbide, which is applied in the field of conductive silicon carbide foamed ceramic materials and its preparation, can solve the problems of difficult control of pore volume and size, non-dense foamed silicon carbide ceramics, and low initial density, and it is easy to achieve porosity Control, low preparation cost, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

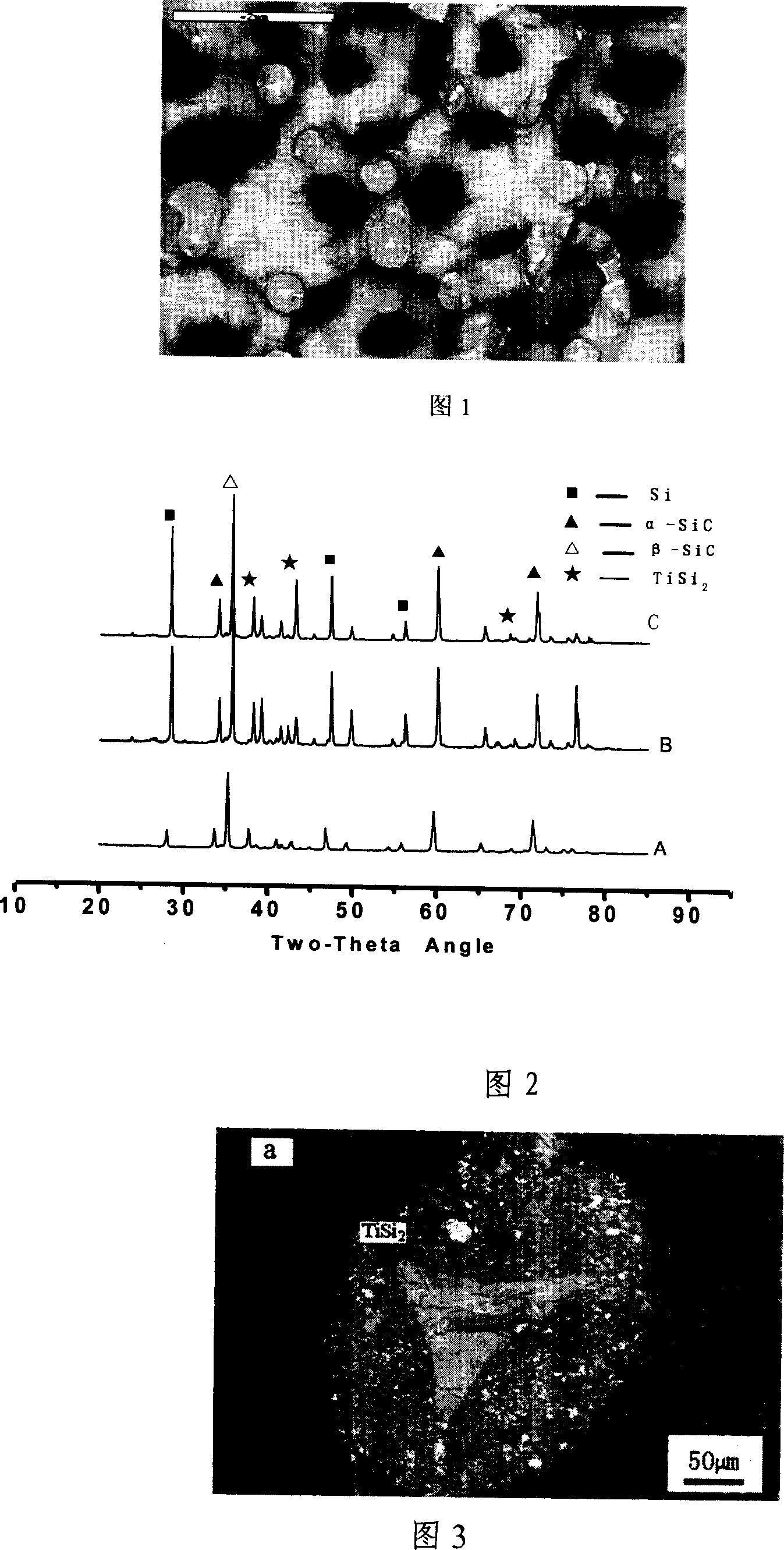

Embodiment 1

[0044] Co-dissolve silicon carbide powder with an average particle size of 2 μm, aminophenol-formaldehyde resin, titanium powder with an average particle size of 5 μm, and p-toluenesulfonic acid with a weight ratio of 55%: 35%: 5%: 5% in absolute ethanol to make a slurry (the solute content is 30%), the polyurethane foam of pore diameter 1mm is cut into required size and is immersed in the described slurry evenly, soaks 1 minute, after taking out, squeeze out excess slurry, after air-drying, 50 ℃ of semi-cured 10 Minutes, put it into a high-pressure container, fill it with nitrogen to make the air pressure reach 12MPa, raise the temperature to 250°C, and keep it warm for 1 hour to solidify. Under the protection of argon, it is pyrolyzed to form a carbon skeleton; the heating rate is 2°C per minute, the temperature is raised to 800°C, and the temperature is kept for 0.5 hours. Vacuum siliconize the titanium-containing carbon skeleton (add silicon powder 3 times the weight of th...

Embodiment 2

[0046] Co-dissolve silicon carbide powder with an average particle size of 2 μm, epoxy resin (brand name EP0141-310), titanium powder with an average particle size of 3.5 μm, and p-toluenesulfonic acid with a weight ratio of 37%: 55%: 5%: 3% In water ethanol, make a slurry (solute content is 40%), cut the polyurethane foam with a pore diameter of 2mm into the required size and immerse it evenly in the slurry, soak for 1 minute, squeeze out the excess slurry after taking it out , after air-drying and semi-curing at 50°C for 10 minutes, put it into a high-pressure container, fill it with nitrogen to make the air pressure reach 10MPa, raise the temperature to 200°C, and keep it for 1 hour to cure. Under the protection of argon, it is pyrolyzed to form a carbon skeleton; the heating rate is 2°C per minute, the temperature is raised to 900°C, and the temperature is kept for 0.5 hours. Vacuum siliconize the carbon skeleton (add silicon powder twice the weight of the carbon skeleton ...

Embodiment 3

[0048] The thermosetting phenolic resin and furfural resin with a weight ratio of 50% were co-dissolved in absolute ethanol to make a slurry solution, and then the weight ratio was respectively 94%: 6% silicon carbide powder with an average particle size of 5 μm and an average Titanium powder with a particle size of 3.5 μm is uniformly added to the above solution to form a slurry with a resin / silicon carbide powder volume ratio of 1 / 9 (solute content is 20%). Cut the polyurethane foam with a pore diameter of 2mm into the required size and immerse it evenly in the slurry, take it out and squeeze out the excess slurry, soak for 1 minute, air-dry and semi-cure at 50°C for 10 minutes, put it in a high-pressure container, Infuse nitrogen gas to make the air pressure reach 11MPa, raise the temperature to 230°C, and keep the temperature for 1 hour to cure. Under the protection of argon, it is pyrolyzed to form a carbon skeleton; the heating rate is 2°C per minute, the temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Room temperature resistivity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com