Graphene-coated conductive fiber and preparation method thereof

A conductive fiber and graphene technology, applied in fiber types, fiber processing, textiles and papermaking, etc., can solve the problems of low interaction force between fiber and graphene, and weak adhesion of graphene, so as to achieve low raw material cost and not easy to fall off , the effect of controllable resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

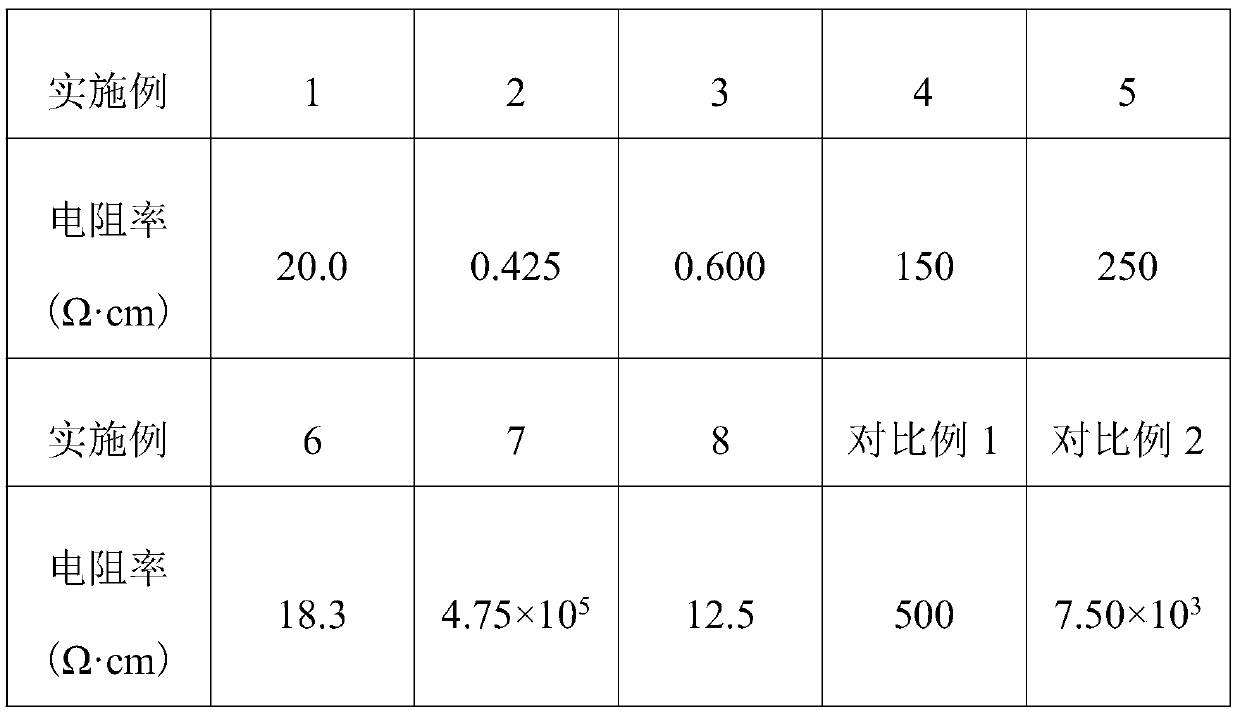

Embodiment 1

[0027] Embodiment 1 graphene-coated conductive fiber

[0028] (1) Immerse the nylon fiber in 1g / L casein solution for 10 minutes, wherein the pH of the casein solution is 11, the concentration of the pH regulator NaOH is 0.1mol / L, and then dry the fiber at 65°C;

[0029] (2) Place the fiber prepared in step (1) into distilled water and gently wash it for 5 seconds to wash away excess casein on the surface of the fiber, and then dry it at 65°C;

[0030] (3) The fiber prepared by step (2) was immersed in the 400nm graphene oxide solution with a sheet diameter of 2g / L for 2 minutes, the pH of the graphene oxide solution was 2, and the concentration of pH regulator formic acid was 0.4mol / L, and then Dry at 65°C;

[0031] (4) The fibers prepared in step (3) were reduced in 6 g / L formamidine sulfinic acid at 95° C. for 12 hours, and the composite fibers were washed with distilled water to obtain graphene-coated conductive fibers.

Embodiment 2

[0032] Example 2: Graphene-coated conductive fibers

[0033] (1) Vibrating and dipping the nylon fiber in 1g / L casein solution for 30 minutes, wherein the pH of the casein solution is 12, the concentration of the pH regulator KOH is 0.1mol / L, and then the fiber is naturally air-dried;

[0034] (2) Place the fibers prepared in step (1) into distilled water and gently wash them for 5 seconds to wash off excess casein on the surface of the fibers, and then air-dry them naturally;

[0035] (3) Oscillating and immersing the fiber prepared in step (2) in a 400nm graphene oxide solution with a sheet diameter of 2g / L for 30 minutes, the pH of the graphene oxide solution was 3, and the formic acid concentration of the pH regulator was 0.4mol / L. Dry at 65°C; repeat this step 5 times;

[0036] (4) Place the fiber prepared in step (3) in a 50 g / L vitamin C solution at 70° C. for 15 hours, and wash the composite fiber with distilled water to obtain a graphene-coated conductive fiber.

[...

Embodiment 3

[0038] Embodiment 3: graphene-coated conductive fiber

[0039] (1) Ultrasonic immersion of nylon fiber in 1g / L casein solution for 10 minutes, wherein the pH of the casein solution is 14, the concentration of pH regulator NaOH is 0.1mol / L, and then dried at 65°C;

[0040] (2) Place the fiber prepared in step (1) into distilled water and gently wash it for 5 seconds to wash away excess casein on the surface of the fiber, and then dry it at 65°C;

[0041] (3) Oscillating and immersing the fiber prepared in step (2) in a 10 μm graphene oxide solution with a sheet diameter of 2 g / L for 30 minutes, the pH of the graphene oxide solution was 1, and the formic acid concentration of the pH regulator was 0.4 mol / L. Dry at 65°C; repeat this step 5 times;

[0042] (4) The fibers prepared in step (3) were placed in a 10 g / L vitamin C solution for hydrothermal reduction at 120° C. for 10 h, and the composite fibers were washed with distilled water to obtain graphene-coated conductive fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com