In situ polymerization one-dimensional electric high purity carbon/polyacrylonitrile composite polymer

A composite polymer and polyacrylonitrile technology, applied in the field of composite polymers, to achieve the effects of easy control of process conditions, good dispersion performance, and good process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

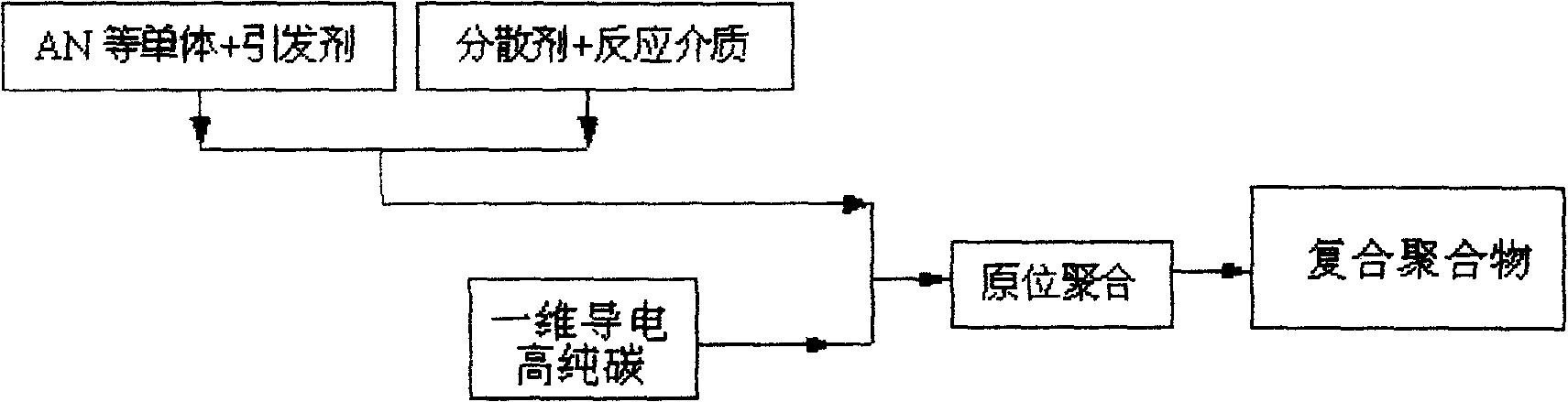

Method used

Image

Examples

Embodiment 1

[0019] Example 1: 5 parts of carbon nanotubes (average diameter 0.015 μm, average length 10 μm) were used in a mixed solution of 95 parts of acrylonitrile, 4 parts of methyl acrylate, 1 part of itaconic acid and 300 parts of dimethyl sulfoxide Ultrasonic dispersion 4h, so that the carbon nanotubes dispersed evenly. Transfer these mixtures to a reaction kettle, stir with an electric mechanical stirrer (rotating speed 560r / min) for 20min under the protection of nitrogen, add 2 parts of azobisisobutyronitrile as an initiator, and heat the reaction kettle to 65°C after the dissolution is complete , and react at constant temperature for 24h to obtain a black composite polymer solution. The reaction product was transferred to a vacuum distillation device, and the unreacted acrylonitrile and methyl acrylate monomers were evaporated under reduced pressure at a vacuum degree of 150 mmHg and a temperature of 50°C. Then the temperature is raised to 60°C and after defoaming and filtering...

Embodiment 2~9

[0020] Examples 2-9: The preparation method is similar to that of Example 1, but the reaction conditions are as shown in Table 1.

[0021] Table 1 Embodiment 2~9 solution polymerization reaction conditions and the spinning performance of composite polymer

[0022]

composition

monomer ratio

carbon nanotubes

reaction medium

Initiator

molecular weight

degree(℃)

when reacting

room (h)

Product spinning

silk properties

implement

Example 2

AN 100

SWNT 5

DMF 150

AIBN 3

0

60

48

Difference

implement

Example 3

AN 100, MA

15

MWNT 1

DMAc 900

BPO 1

IPA 3

72

36

it is good

implement

Example 4

AN 100,

MAA 3

VGCF 5 ...

Embodiment 10

[0025] Example 10: 1 part of sodium dodecylsulfonate, 2 parts of hydrogen peroxide and 1 part of ascorbic acid were dissolved in 300 parts of water in a reactor with electric stirring (rotating speed 600 r / min). Add 5 parts of vapor-grown carbon fibers (average diameter 0.150 μm, average length 10 μm) to a mixed solution of 95 parts of acrylonitrile, 4 parts of methyl methacrylate, and 1 part of acrylic acid, and disperse them with ultrasonic waves for 4 hours. And continue to stir for 10min. Raise the temperature of the reactor to 50° C. and keep it constant, and react monomers such as acrylonitrile for 8 hours to obtain a black precipitate. Filter the precipitate, wash it twice with 1000 parts of cold water, hot water (about 70°C), and ethanol successively, each time for 20 minutes, put it into a 60°C vacuum oven and dry it for 24 hours after suction filtration, and obtain the vapor phase grown carbon fiber / polyacrylonitrile composite polymer. Dissolve 18 parts of dry vapo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com