A kind of polyimide fiber paper-based insulating material and preparation method thereof

A polyimide fiber, insulating material technology, applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems of poor thermal stability and low strength, and achieve good thermal stability, high mechanical properties, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

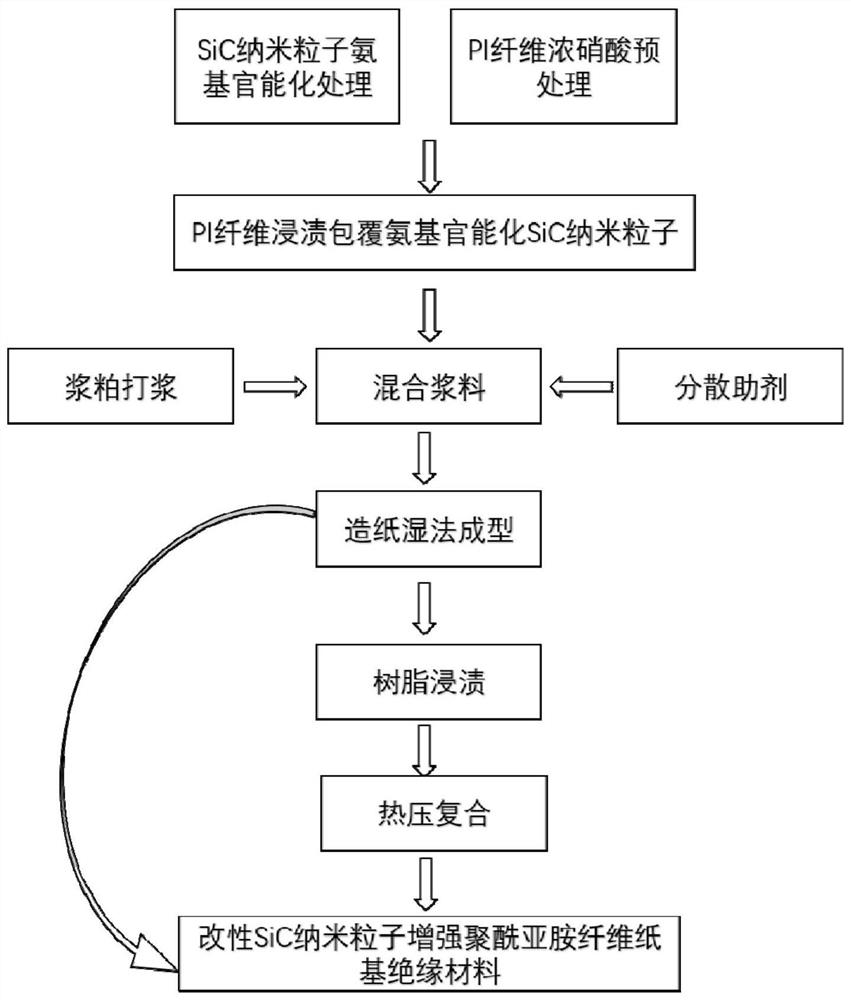

Method used

Image

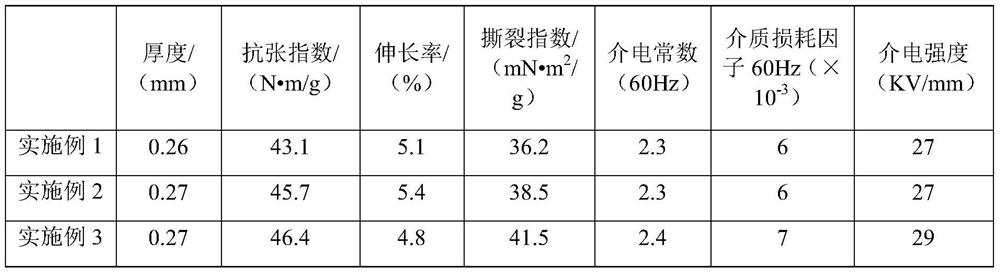

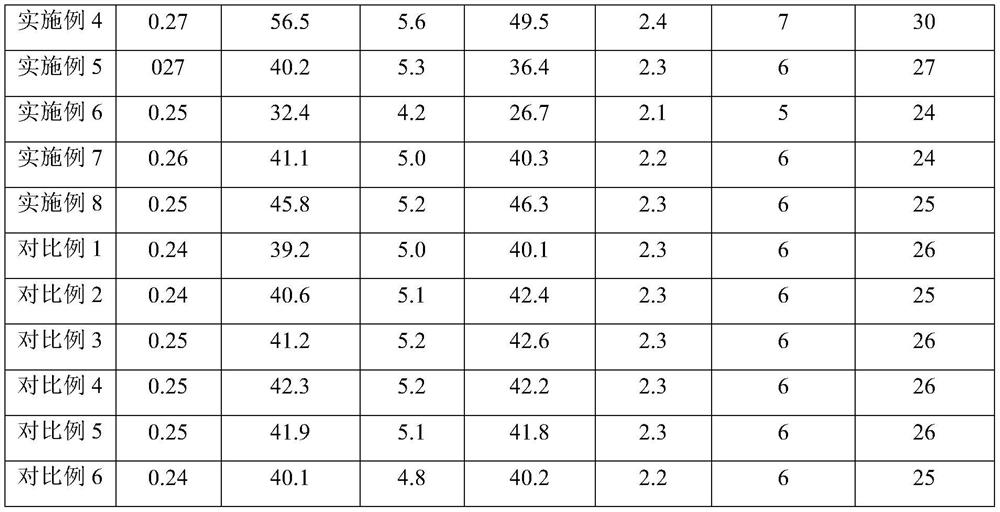

Examples

Embodiment 1

[0046] An unmodified SiC nano particle reinforced polyimide fiber paper-based insulating material and a preparation method thereof, comprising the following steps:

[0047] (1) soak 65wt% concentrated nitric acid solution for 3 hours to the PI fiber with a concentration of 6 mm in length, and take it out;

[0048] (2) Preparation of 2.0wt% unmodified original SiC nanoparticles impregnation mixed solution: 2g of unmodified original SiC nanoparticles and 100mL acetone were mixed and stirred for 3h, ultrasonically dispersed for 30min to obtain a pre-impregnated nanoparticle mixed solution, and then the step ( 1) After soaking the obtained PI fiber in the above dispersion liquid for 10s, take it out and dry it at 105°C for 4h;

[0049] (3) For the beating of aramid pulp, the beating degree is 55°SR, according to the quantitative 100g / m 2 The base paper prepared mixed slurry, adding mixed fiber is 90%, PI fiber: the mass ratio of aramid pulp is 1:1; Auxiliary CPAM, PEO, carboxylat...

Embodiment 2

[0053] A modified SiC nanoparticle reinforced polyimide fiber paper-based insulating material and a preparation method thereof, comprising the following steps:

[0054] (1) Amino functionalization of SiC nanoparticles: Dissolve 2g of SiC nanoparticles in 30mL of absolute ethanol, add 2g of 3-aminopropyltrimethylsilane and 4mL of deionized water, mix and stir at 80°C for 2h, Centrifuge, dry, and complete the amino modification treatment;

[0055] (2) soak 65wt% concentrated nitric acid solution for 3 hours to the PI fiber whose length is 6mm, and take it out;

[0056] (3) Preparation of 0.5wt% amino-modified SiC nanoparticles impregnating mixed solution: 0.5g of amino-functionalized modified SiC nanoparticles and 100mL of acetone were mixed and stirred for 3 hours, and ultrasonically dispersed for 30 minutes to obtain a pre-impregnated modified nanoparticles mixed solution; (2) Immerse the treated PI fiber in the modified nanoparticle mixture prepared above for 10 seconds, and...

Embodiment 3

[0061] A modified SiC nanoparticle reinforced polyimide fiber paper-based insulating material and a preparation method thereof, comprising the following steps:

[0062] (1) Amino functionalization of SiC nanoparticles: Dissolve 2g of SiC nanoparticles in 30mL of absolute ethanol, add 2g of 3-aminopropyltrimethylsilane and 4mL of deionized water, mix and stir at 80°C for 2h, Centrifuge, dry, and complete the amino modification treatment;

[0063] (2) soak 65wt% concentrated nitric acid solution for 3 hours to the PI fiber whose length is 6mm, and take it out;

[0064] (3) Preparation of 1.0wt% amino-modified SiC nanoparticles impregnation mixed solution: 1 g of amino-functionalized modified SiC nanoparticles and 100 mL of acetone were mixed and stirred for 3 h, and ultrasonically dispersed for 30 min to obtain a pre-impregnated modified nano-particle mixed solution; ( 2) The treated PI fiber was immersed in the modified nanoparticle mixture prepared above for 10 seconds, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com