Aperture-controllable porous electrode and preparation method thereof

A porous electrode, pore size technology, applied in the preparation/purification of carbon, nanotechnology for materials and surface science, nanotechnology, etc. Electrode film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

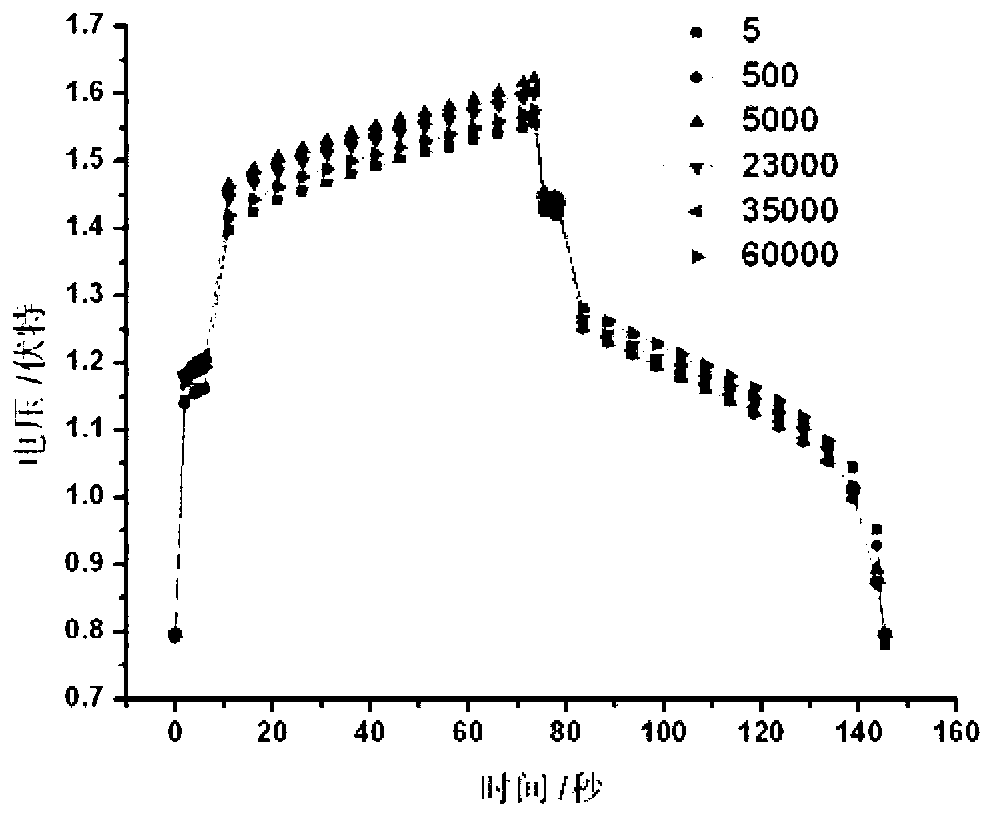

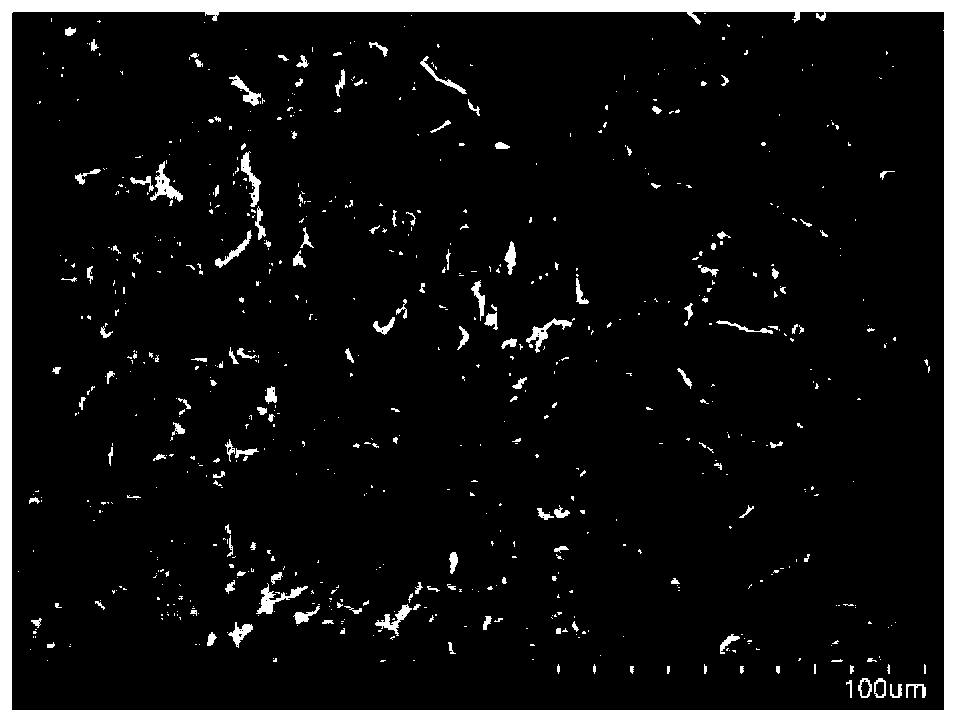

[0023] With carbon nanotubes as the carbon material, PTFE emulsion as the binder, polyethylene glycol 400 as the pore-forming agent, the mass ratio of carbon nanotubes to PTFE is 95:5, and the mass of polyethylene glycol is the sum of the mass of the former two 30% of the above three materials, blend the above three materials, add isopropanol to disperse and stir evenly, prepare wet powder carbon particle materials, and then carry out rolling operation to form electrode sheets with a thickness of 1mm, the surface is dense and uniform, and cut according to the size of battery electrodes Cut and bake in an oven at 180°C for 3 hours. figure 1 is the scanning electron microscope image of the prepared carbon nanotube porous electrode, the average pore diameter of the porous electrode is 0.1-2 μm, and the pore diameter distribution is uniform. The prepared porous electrode has good liquid absorption performance, and the porosity reaches 80%. Take out the porous electrode sheet, ass...

Embodiment 2

[0025] Graphene is used as carbon material, PTFE emulsion is used as binder, polyethylene glycol 400 is used as pore forming agent, the mass ratio of graphene and PTFE is 90:10, and the quality of polyethylene glycol is 40% of the total mass of the former two. %, blend the above three materials, add isopropanol to disperse and stir evenly, prepare wet powder carbon particle material, and then carry out rolling operation to form an electrode sheet with a thickness of 1mm. The surface is dense and uniform, and it is cut according to the size of the battery electrode. Place in an oven and bake at 150°C for 5h. image 3 Scanning electron microscope image of the prepared graphene porous electrode, from image 3 It can be seen that the average pore size of the porous electrode is 10-50 μm, and the pore size distribution is uniform. The prepared porous electrode has good liquid absorption performance, and the porosity reaches 85%.

Embodiment 3

[0027]The mixture of carbon nanotubes and graphene is used as carbon material, the mass ratio of carbon nanotubes and graphene is 3:1, PTFE emulsion is used as binder, polyethylene glycol 400 is used as pore-forming agent, and the mass ratio of carbon materials to PTFE is 95:5, the mass of polyethylene glycol is 40% of the total mass of the first two, blend the above three materials, add isopropanol to disperse and stir evenly, prepare wet powder carbon particle material, and then carry out rolling operation to form a thickness It is a 1mm electrode sheet with a dense and uniform surface, cut according to the size of the battery electrode, and placed in an oven for 3 hours at 180°C. The prepared porous electrode has good liquid absorption performance, and the porosity reaches 83%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com