Preparation method and applications of multi-level pore structure metal organic framework material

A metal-organic framework and metal-organic framework technology, which is applied in the field of preparation of metal-organic framework materials with a hierarchical porous structure, can solve the problems of unstable performance of metal-organic framework materials, and the preparation method is not universal, and achieves mild conditions, Simple preparation process and controllable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

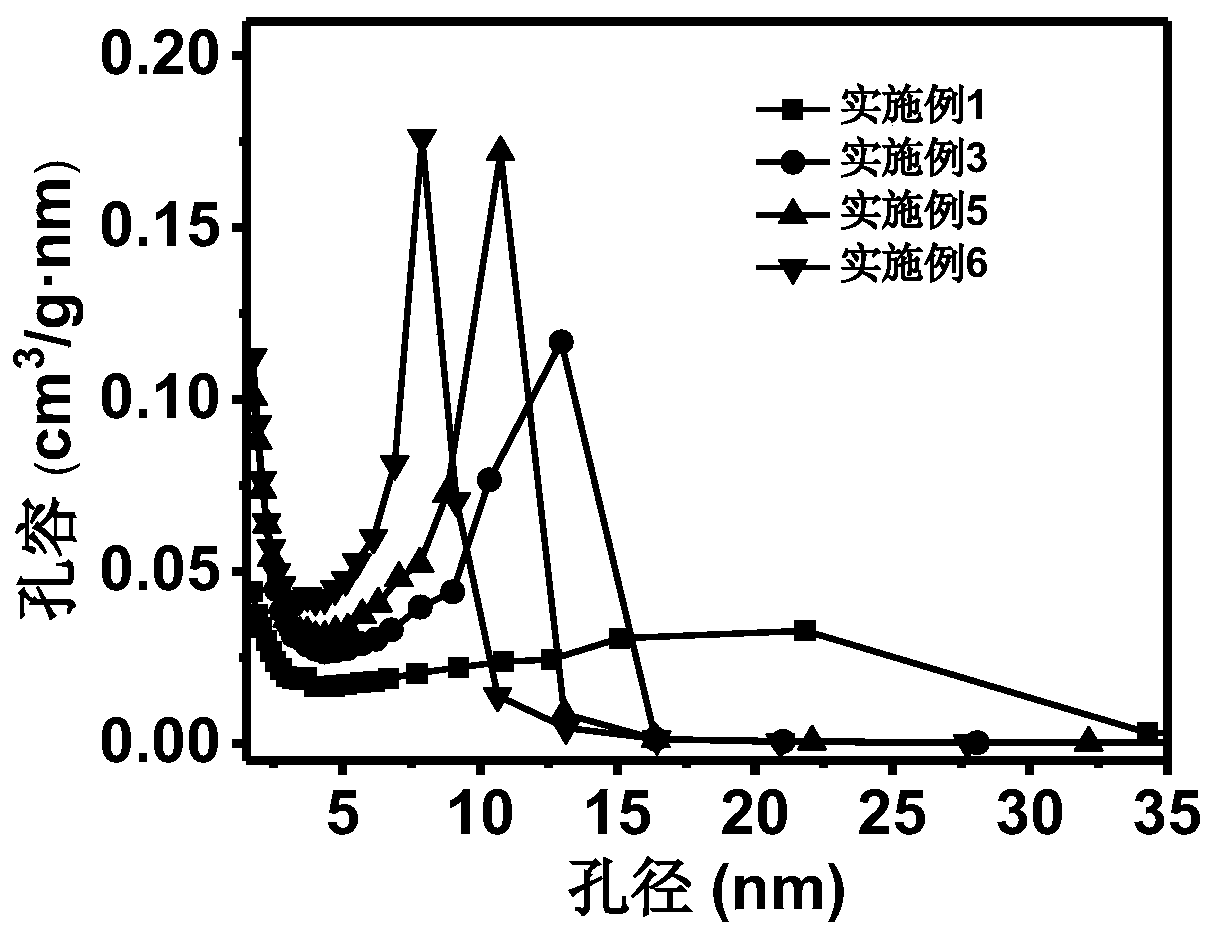

Embodiment 1

[0033] A method for preparing a metal-organic framework material with a hierarchical porous structure, specifically comprising the following steps:

[0034] 160mg hafnium chloride (0.5mmol), 83mg terephthalic acid (0.5mmol), 18ml N,N-dimethylformamide (0.234mol), 1ml formic acid (0.026mol) and 3ml deionized water (0.167mol) Add it into the reaction kettle, stir it evenly with ultrasonic, then conduct a hydrothermal reaction at a reaction temperature of 123°C for 48 hours. After the hydrothermal reaction is completed, cool it to room temperature at a cooling rate of 2°C / min, and then centrifuge to obtain multi-stage pores For the crude metal organic framework material, at this cooling rate, the unreacted ligand can be crystallized in the form of a uniform octahedron, which is convenient for the subsequent purification of the product;

[0035] Soak the crude metal-organic framework material with a hierarchical porous structure in methanol and dichloromethane for three days, cent...

Embodiment 2

[0037] A method for preparing a metal-organic framework material with a hierarchical porous structure, specifically comprising the following steps:

[0038] 160mg hafnium chloride (0.5mmol), 83mg terephthalic acid (0.5mmol), 18ml N,N-dimethylformamide (0.234mol), 1m acetic acid (0.017mol) and 1ml deionized water (0.055mol) Add it into the reaction kettle, stir it evenly with ultrasonic, then conduct a hydrothermal reaction at a reaction temperature of 123°C for 48 hours. After the hydrothermal reaction is completed, cool it to room temperature at a cooling rate of 2°C / min, and then centrifuge to obtain multi-stage pores For the crude metal organic framework material, at this cooling rate, the unreacted ligand can be crystallized in the form of a uniform octahedron, which is convenient for the subsequent purification of the product;

[0039] Soak the crude metal-organic framework material with a hierarchical porous structure in methanol and dichloromethane for three days, centr...

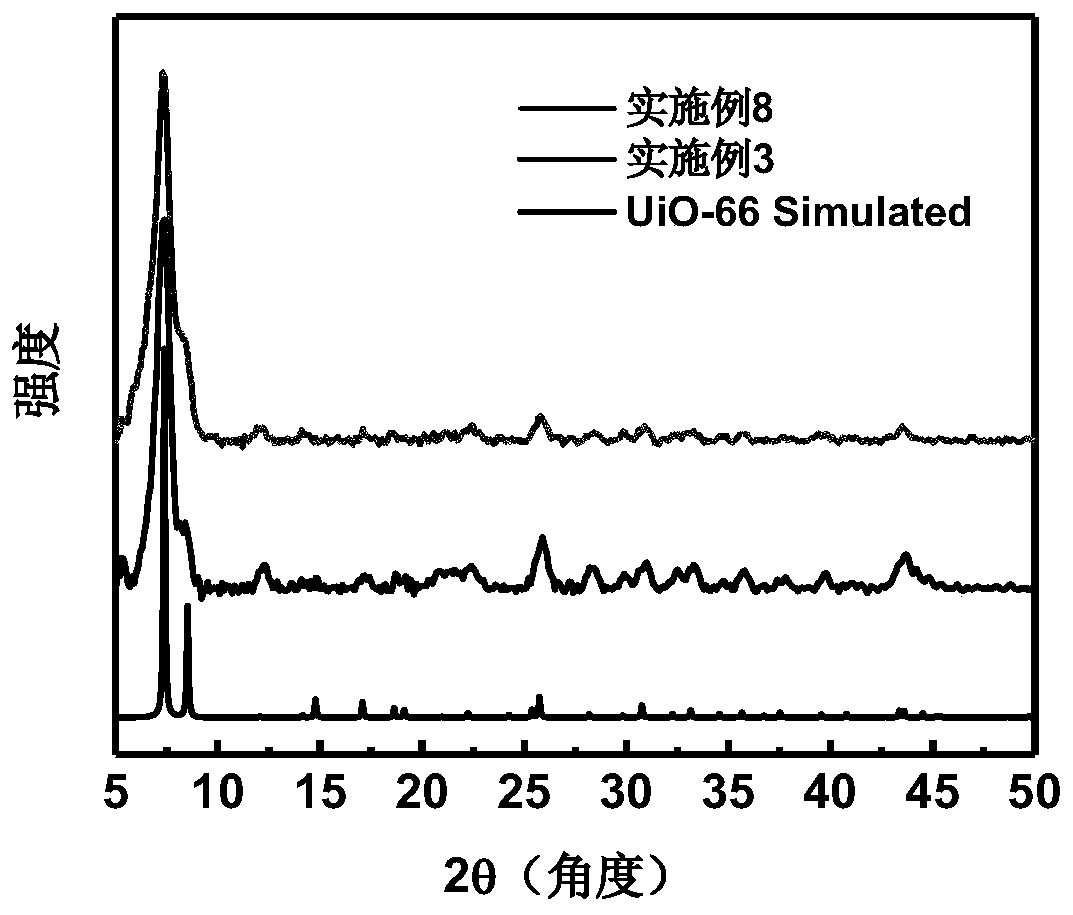

Embodiment 3

[0041] A method for preparing a metal-organic framework material with a hierarchical porous structure, specifically comprising the following steps:

[0042]160mg hafnium chloride (0.5mmol), 83mg terephthalic acid (0.5mmol), 18ml N,N-dimethylformamide (0.234mol), 1m acetic acid (0.017mol) and 3ml deionized water (0.167mol) Add it into the reaction kettle, stir it evenly with ultrasonic, then conduct a hydrothermal reaction at a reaction temperature of 123°C for 48 hours. After the hydrothermal reaction is completed, cool it to room temperature at a cooling rate of 2°C / min, and then centrifuge to obtain multi-stage pores For the crude metal organic framework material, at this cooling rate, the unreacted ligand can be crystallized in the form of a uniform octahedron, which is convenient for the subsequent purification of the product;

[0043] Soak the crude metal-organic framework material with a hierarchical porous structure in methanol and dichloromethane for three days, centri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com