Process of preparing polymer porous leg by separation and combination of paraffin microballons porous making agent and thermotropic phase

A thermally induced phase separation method and thermally induced phase separation technology, which are applied in medical science, prosthesis, surgery, etc., can solve the problems of difficult to obtain large-sized pores, difficult to precisely control the pore size, lengthy preparation process, etc., and achieve porosity High, easy to operate, good hole connectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of poly-L-lactic acid (PLLA) porous scaffold

[0029] Wax ball particles were prepared by suspension method. In an Erlenmeyer flask, add 40g of solid paraffin and 200mL of 20mg / mL aqueous gelatin solution, heat to 80°C, and the paraffin becomes liquid. Stir with an electromagnetic stirrer at a stirring speed of 200 rpm to disperse the liquid paraffin into small droplets. After the state of the paraffin suspension is stable, it is quickly poured into ice water at 0° C. for quenching to obtain solid paraffin microspheres. The paraffin microspheres were classified by domestic standard sieves, and the paraffin microspheres with a particle size of 150-450 μm were obtained.

[0030] In a stainless steel mold, the paraffin microspheres were uniformly mixed with the PLLA / dioxane solution with a concentration of 0.06 g / mL, and the amount of the paraffin microspheres was 1.3 g per milliliter of the PLLA solution. The above mixture was frozen at -2...

Embodiment 2

[0031] Embodiment 2: the control of poly-L-lactic acid (PLLA) porous scaffold aperture

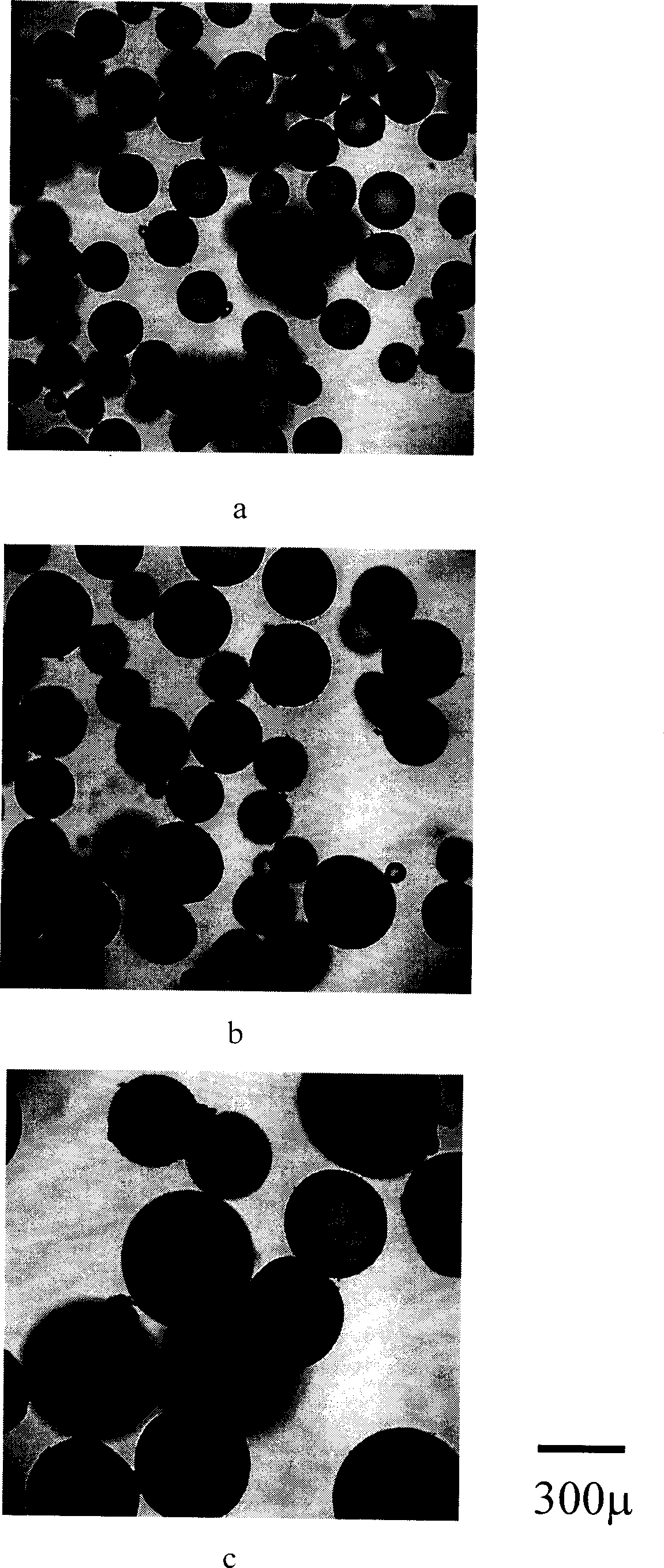

[0032] Prepare paraffin microspheres according to the method in Application Example 1, and use domestic standard sieves to divide paraffin microspheres into different fractions below 150 μm, 150-280 μm and 280-450 μm according to the particle size, such as figure 2 a. figure 2 b and figure 2 as shown in c.

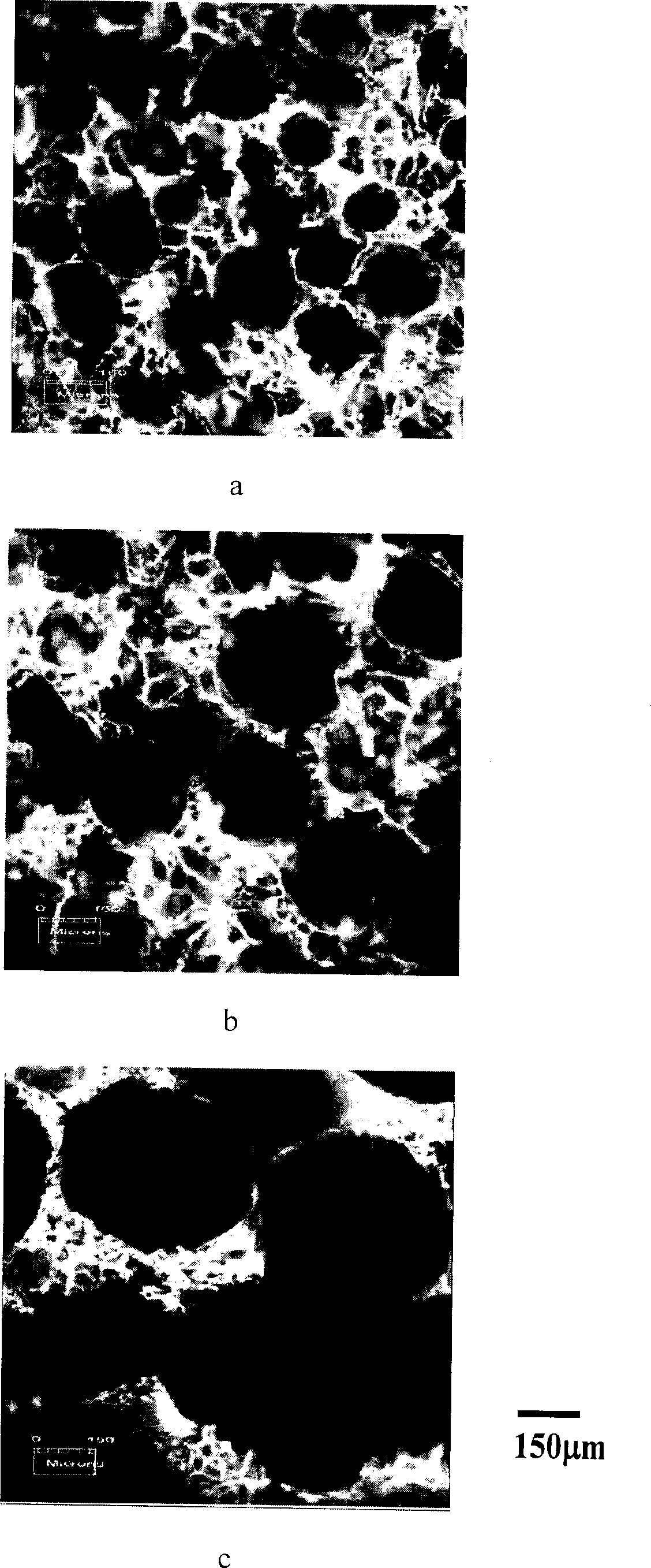

[0033] The above-mentioned paraffin microspheres with different particle sizes were used to prepare PLLA porous scaffolds according to the method in Example 1, wherein the concentration of PLLA solution was 0.05 g / mL, and the amount of paraffin microspheres was 1.6 g per milliliter of PLLA solution. The laser confocal micrographs of the obtained PLLA porous scaffold are as follows: image 3 a. image 3 b and image 3 as shown in c. Depend on image 3 It can be seen that the pore size of the porous scaffold can be conveniently controlled by controlling the particle size of the p...

Embodiment 3

[0034] Embodiment 3: the control of the porosity and apparent density of poly-L-lactic acid (PLLA) porous scaffold

[0035] Paraffin microspheres with different particle sizes, different concentrations of PLLA solutions, and different dosages of paraffin microspheres were used, and the PLLA porous scaffold was prepared according to the method in Example 1. Table 1 summarizes the porosity and apparent density of the PLLA porous scaffolds prepared under various conditions. It can be seen from Table 1 that the porosity and apparent density of porous scaffolds have nothing to do with the particle size of paraffin microspheres, but are greatly affected by the concentration of PLLA solution and the amount of wax balls. At a higher concentration of PLLA solution, the obtained porous scaffold has higher apparent density and lower porosity; the greater the amount of paraffin microspheres, the lower apparent density and higher porosity of the obtained scaffold. Figure 4 a. Figure 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com