Use of crosslinking type polybenzimidazole porous separating membrane in liquid flow battery

A polybenzimidazole and porous separation membrane technology, which is applied to fuel cell components, fuel cells, collectors/separators, etc., can solve the problems of poor ion selectivity, limited application, and high price, and achieve controllable pore size , Solve the effect of capacity attenuation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

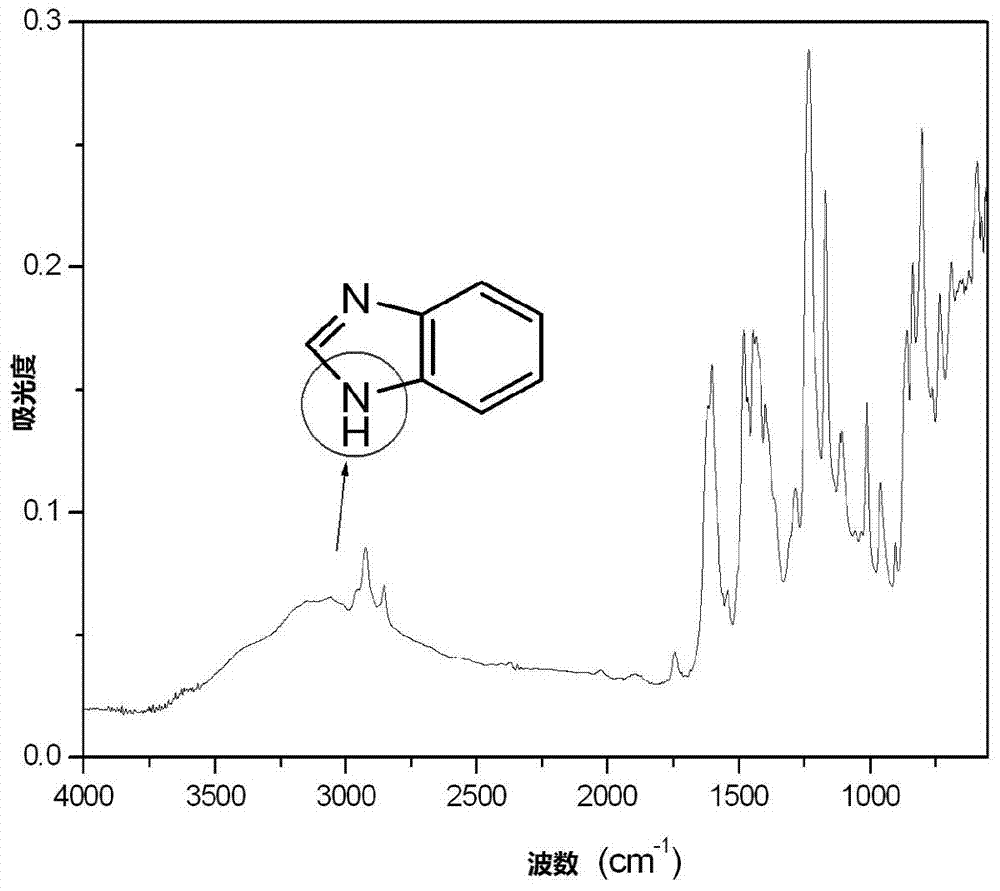

[0043] Dissolve 10 g of polybenzimidazole (weight average molecular weight about 50,000) with the following structure in 50 ml of N,N-dimethylacetamide to make a 20% polymer solution. The solution was cast onto a glass plate and flattened with a casting knife. Then quickly immersed in 5L water, solidified for 5 minutes to form a porous separation membrane ( figure 1 ), to obtain a porous membrane of polybenzimidazole. The porous separation membrane of polybenzimidazole was cross-linked in 5% methanol solution of p-dichlorobenzylbenzene for 24 hours to obtain a cross-linked polybenzimidazole membrane.

[0044]

[0045] n represents the number of structural units of the polymer, 10≤n≤200.

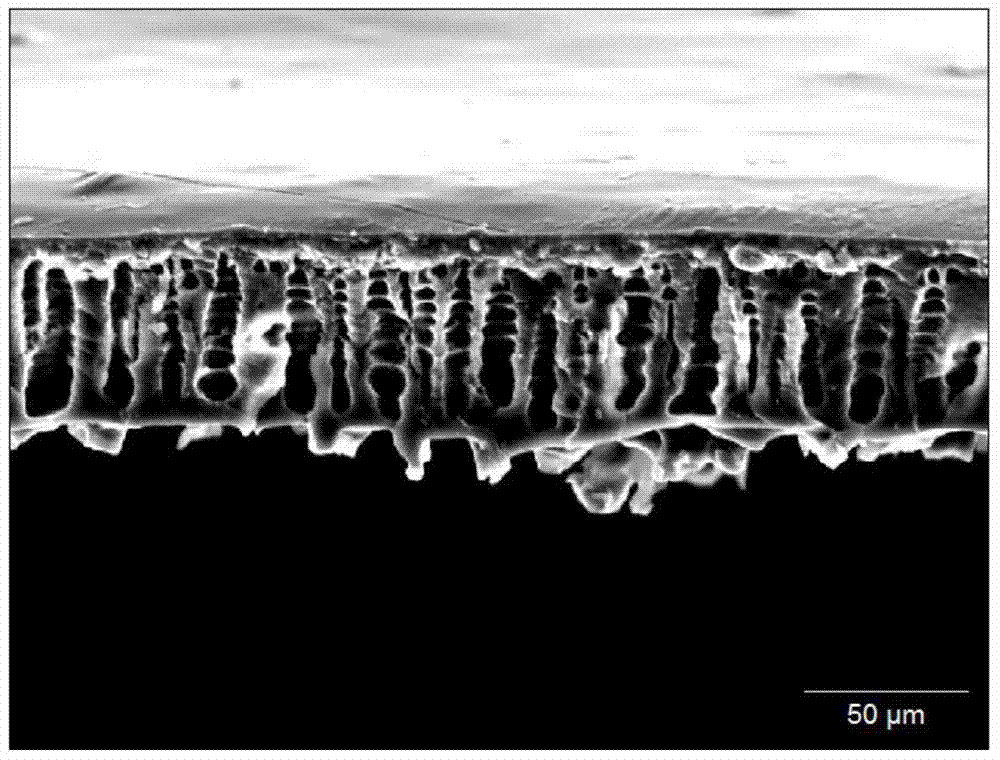

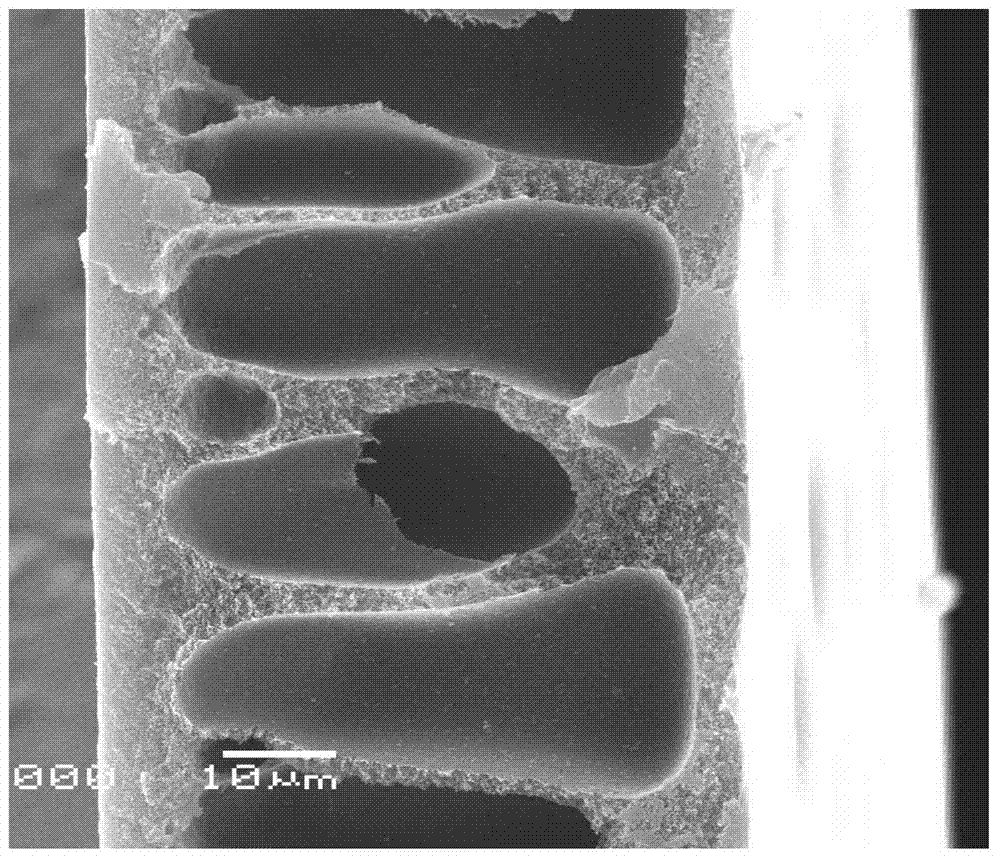

[0046] in figure 2 The cross-sectional electron microscope picture of the solvent-resistant nanofiltration membrane prepared in Example 1 is given. The membrane material exhibits a traditional finger-like pore structure. The cross-linked polybenzimidazole porous separation membrane pre...

Embodiment 2

[0050] Dissolve 3.4 grams of phosphorus pentoxide in 34 grams of polyphosphoric acid, add it to a 500ml three-necked flask, heat up and stir to form a clear solution, then add 6mmol of biphenyltetramine, 6mmol of 4,4'-dicarboxydiphenyl ether, Stir and heat up to 200°C, react for 20 hours, cool down, and pour into a 5% sodium hydroxide solution. After standing for 24 hours, wash well with water until the solution is neutral. Filter and dry. The prepared polymer was dissolved in DMAC to prepare a 15wt% solution, and the solution was cast onto a glass plate and flattened with a casting knife. Then quickly immersed in 5L of water, solidified for 5 minutes to form a porous separation membrane to obtain a porous membrane of polybenzimidazole. The porous separation membrane of polybenzimidazole was cross-linked in 5% methanol solution of p-dichlorobenzylbenzene for 24 hours to obtain a porous separation membrane with the following chemical structure.

[0051]

[0052] In the em...

Embodiment 3

[0055] Same as Example 1, the polybenzimidazole structure is replaced with the following structure, and the weight average molecular weight is about 50,000.

[0056]

[0057] In the embodiment, n represents the number of structural units of the polymer, and 10≤n≤200.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com