Method for preparing carbon nanofiber based non-noble-metal catalyst through oxidation improved electrostatic spinning

A carbon nanofiber and electrospinning technology, which is applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of less parameter description, lower specific surface, poor stability and repeatability of electrospinning, and achieve operational Simple and controllable, good catalytic activity, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

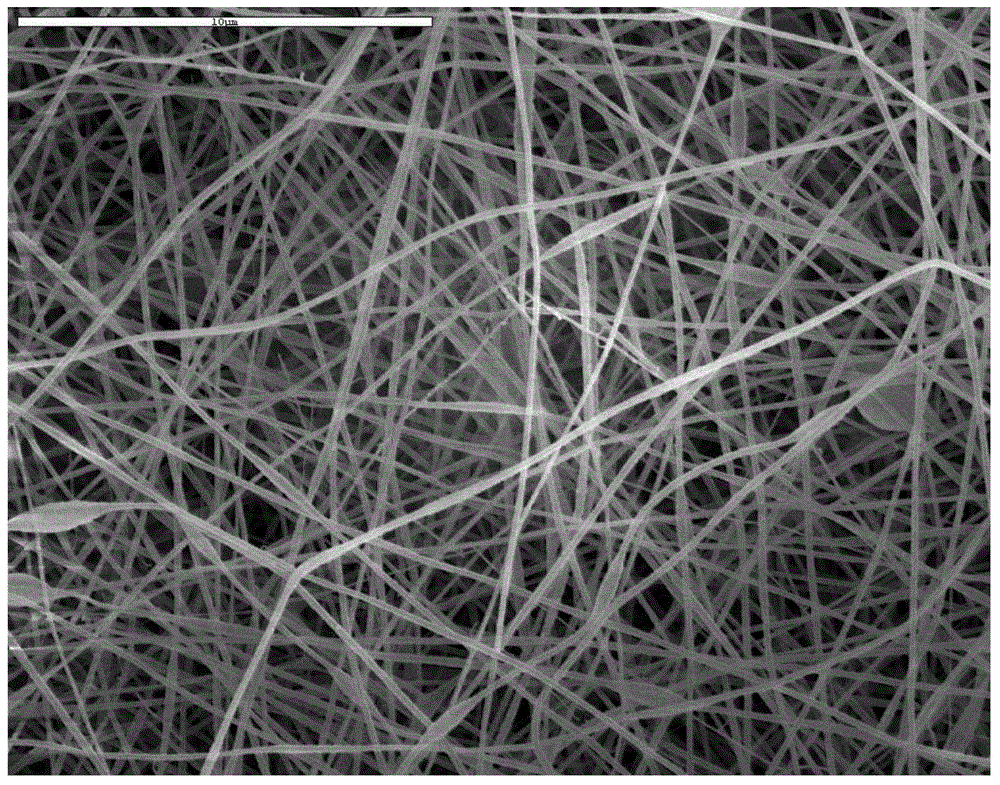

[0046] Example 1: Preparation of iron-containing polyacrylonitrile nanowires by electrospinning

[0047] Configuration solution: Dissolve 5g of polyacrylonitrile in 10g of N,N-dimethylformamide at 50°C, add 3mg of Fe(NO 3 ) 3 9H 2 O Stir well to form a homogeneous clear solution.

[0048] Electrospinning: Fill the prepared solution into the syringe, connect the syringe to the stainless steel needle through the catheter, and control the flow rate of 4mL / h through the micro flow controller to spray the solution through the needle. Aluminum foil was used as the nanofiber collector, and the vertical distance from the needle was 5 cm, and it was grounded at the same time. Connect the needle tube and the aluminum foil to the two poles of the high-voltage generator respectively, and the voltage is 10kV, and the organic nanofibers are started to be obtained on the aluminum foil.

[0049] Observation of the obtained iron-containing polyacrylonitrile nanofibers by scanning electron ...

Embodiment 2

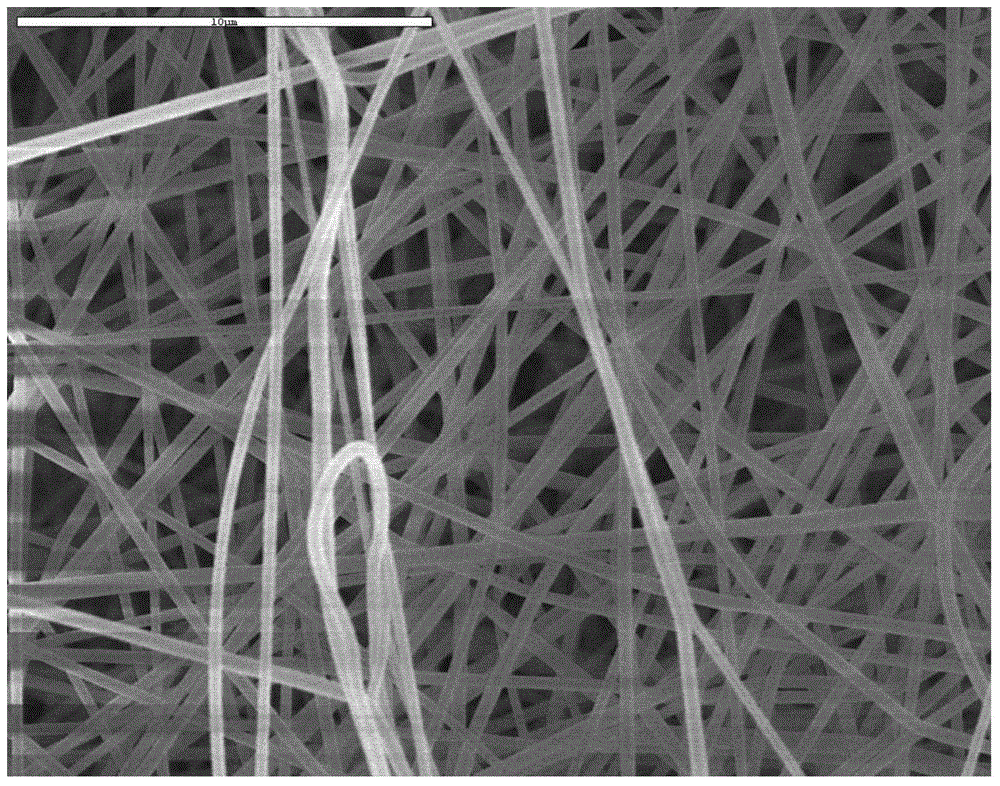

[0050] Example 2: Preparation of iron-containing polyacrylonitrile nanowires by electrospinning

[0051] Configuration solution: Dissolve 2g of polyacrylonitrile in 10g of N,N-dimethylformamide at 50°C, add 0.6mg of Fe(NO 3 ) 3 9H 2 O Stir well to form a homogeneous clear solution.

[0052] Electrospinning: Put the prepared solution into the syringe, connect the syringe to the stainless steel needle through the catheter, and control the flow rate of 1mL / h through the micro flow controller to spray the solution through the needle. Aluminum foil was used as the nanofiber collector, and the vertical distance from the needle was 5 cm, and it was grounded at the same time. Connect the needle tube and the aluminum foil to the two poles of the high-voltage generator respectively, and the voltage is 40kV, and the organic nanofibers are started to be obtained on the aluminum foil.

[0053] Observation of the obtained iron-containing polyacrylonitrile nanofibers by scanning electron...

Embodiment 3

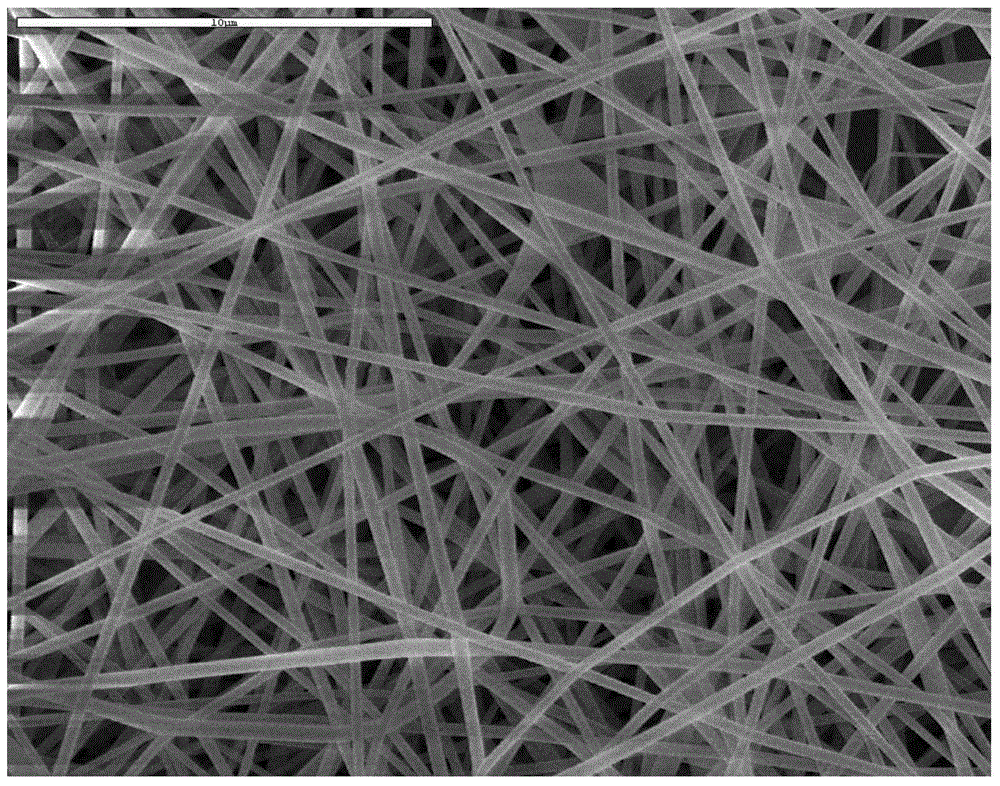

[0054] Example 3: Preparation of iron-containing polyacrylonitrile nanowires by electrospinning

[0055] Configuration solution: Dissolve 0.5g of polyacrylonitrile in 10g of N,N-dimethylformamide at 50°C, add 0.5mg of Fe(NO 3 ) 3 9H 2 O Stir well to form a homogeneous clear solution.

[0056] Electrospinning: Put the prepared solution into the syringe, connect the syringe to the stainless steel needle through the catheter, and control the flow rate of 10mL / h through the micro flow controller to spray the solution through the needle. Aluminum foil was used as the nanofiber collector, and the vertical distance from the needle was 5 cm, and it was grounded at the same time. Connect the needle tube and the aluminum foil to the two poles of the high-voltage generator respectively, and the voltage is 10kV, and the organic nanofibers are started to be obtained on the aluminum foil.

[0057] Observation of the obtained iron-containing polyacrylonitrile nanofibers by scanning elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com