Nitrogen and phosphorus co-doped porous carbon catalyst and preparation method thereof

A technology of co-doping and porous carbon, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve great application potential, simple preparation method, and good electrocatalytic performance for oxygen reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

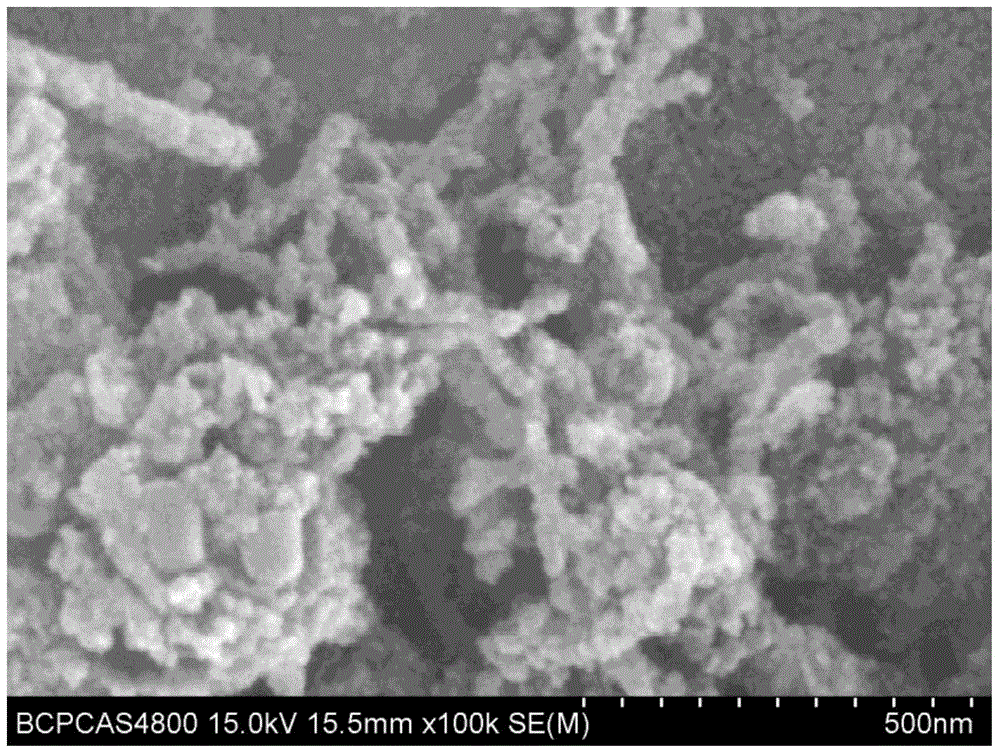

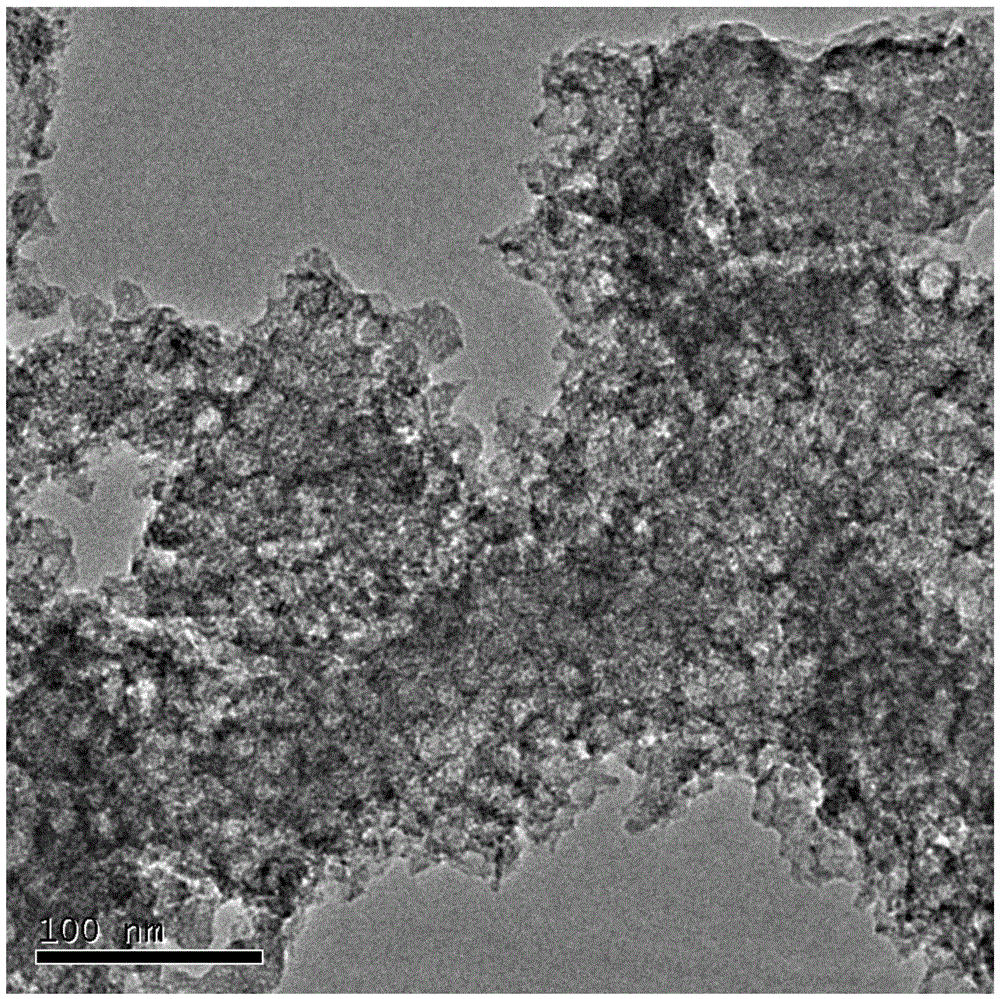

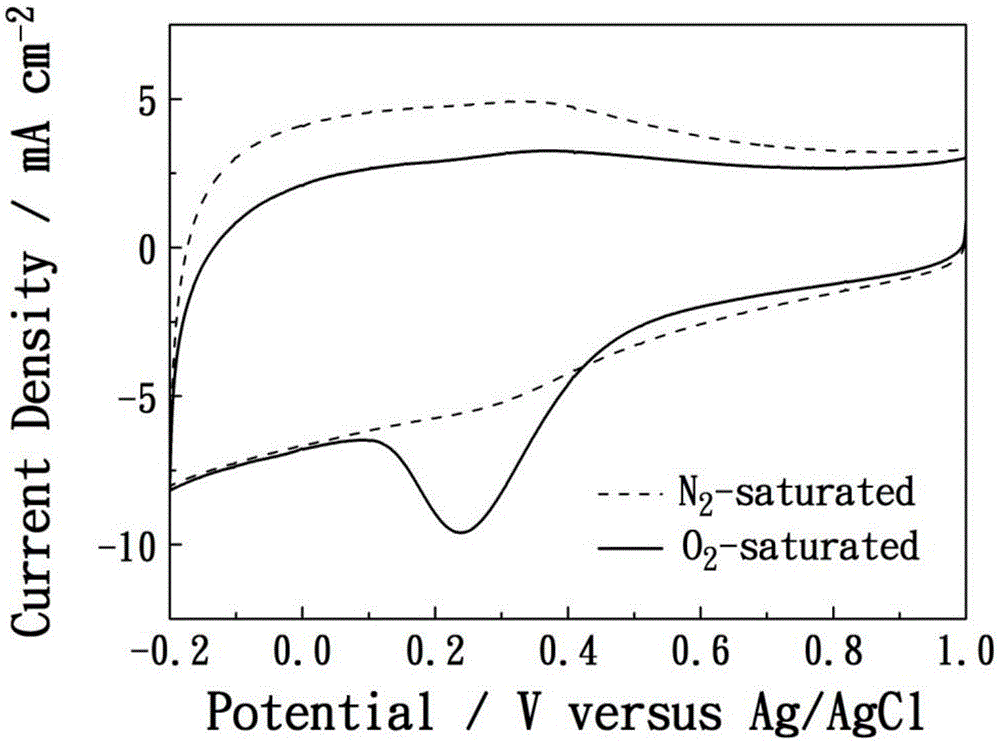

Image

Examples

Embodiment 1

[0027] (1) Add 2g of aniline monomer, 0.34g of tetra-n-butylphosphine bromide, 0.4g of iron phthalocyanine, and 5g of silicon dioxide nanospheres into 10mL of 2mol / L hydrochloric acid solvent, mix well by ultrasonication for 40min, and stir Add 10mL, 1mol / L ammonium persulfate aqueous solution at low temperature, and use an ice-water bath to keep the temperature at 0°C, stir and polymerize for 24h, then transfer to a round-bottomed sesame cake, and place in an oil bath at 100°C for 12h.

[0028] (2) Dry the reactant in a water bath at 80°C to obtain a solid product. Under a nitrogen atmosphere, the solid product is calcined at a high temperature. Specifically, the temperature is raised to 800°C at a rate of 10°C / min, and kept at this temperature for 30 minutes. , naturally cooled to room temperature and taken out to obtain a mixture of nitrogen and phosphorus co-doped porous carbon material and silicon dioxide.

[0029] (3) Grind the taken out solid into powder and weigh it, a...

Embodiment 2

[0031] (1) Add 2g of aniline monomer, 0.1g of iron phosphate, and 4g of silica nanospheres into 10mL of 0.5mol / L sulfuric acid solvent, mix well by ultrasonication for 30min, and add 20ml of 0.925mol / L hydrogen peroxide under stirring solution, and use an ice-water bath to maintain the temperature at 0 ° C for 24 h, then transfer to a round-bottomed pancake, and use an oil bath at 120 ° C for 15 h.

[0032] (2) Dry the reactant in a water bath at 80°C to obtain a solid product. Under a nitrogen atmosphere, the solid product is calcined at a high temperature, specifically, the temperature is raised to 700°C at a rate of 5°C / min, and kept at this temperature for 1h , naturally cooled to room temperature and taken out to obtain a mixture of nitrogen and phosphorus co-doped porous carbon material and silicon dioxide.

[0033] (3) Grind the taken out solid into powder and weigh it, and weigh 1 g of the solid and add it to 40 mL of 4 mol / L ammonium bifluoride aqueous solution to etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com