Preparation and application of nitrogen doped graphene fuel cell catalyst

A nitrogen-doped graphene and catalyst technology, applied in physical/chemical process catalysts, battery electrodes, chemical instruments and methods, etc., can solve the problems of difficult industrialized production, harsh reaction conditions, complex synthesis processes, etc., and achieve low cost of raw materials. , The preparation process is simple and the yield is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

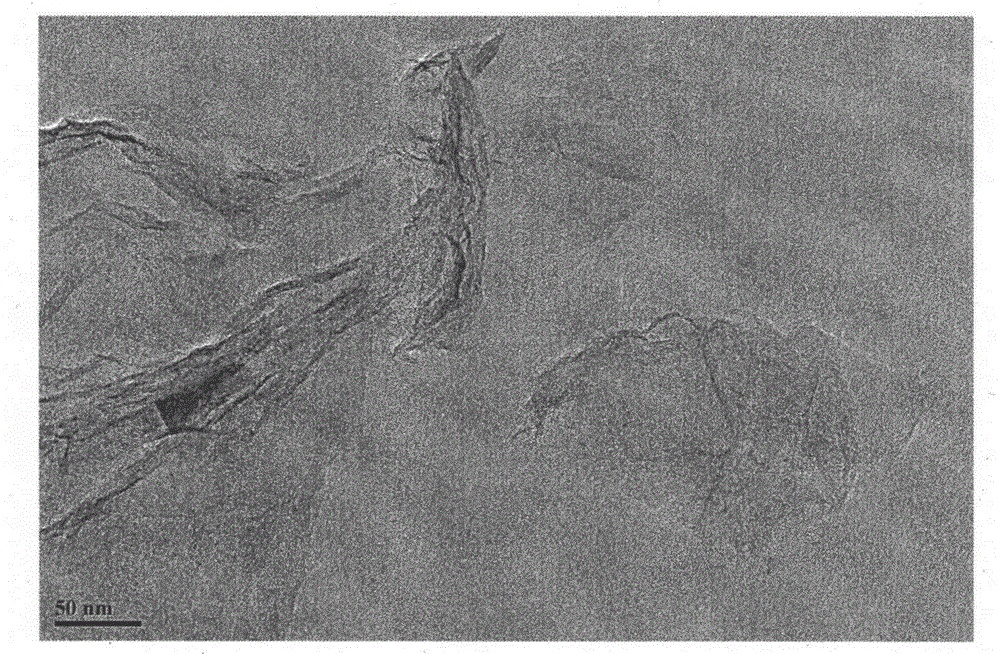

[0030] Preparation of nitrogen-doped graphene C-NG-900: Weigh 0.1600g of graphite oxide and disperse it in 80ml of ethanol, and ultrasonically treat it for 2 hours to obtain a graphene oxide solution. Weigh 0.0600g FeSO at the same time 4 ·7H 2 O, 0.3500g of cyanamide was dispersed in 80ml of ethanol, stirred at 60°C for 2h to obtain a mixed solution. Then, the graphene oxide solution was added dropwise into the above mixed solution, stirring was continued at 60° C. for 12 h, and the solvent was evaporated to obtain a nitrogen-doped graphene precursor. Then, put the precursor in the quartz boat, under N 2 Under the protection of the atmosphere, the temperature was raised to 900°C at a rate of 20°C / min, and kept for 2 hours. 2 After the temperature in the atmosphere is naturally lowered to room temperature, the required nitrogen-doped graphene catalyst is obtained.

Embodiment 2

[0032] Preparation of nitrogen-doped graphene D-NG-900: Weigh 0.1600g of graphite oxide and disperse it in 80ml of ethanol, and ultrasonically treat it for 2 hours to obtain a graphene oxide solution. Weigh 0.0600g FeSO at the same time 4 ·7H 2 O. Disperse 0.3500g of dicyandiamide in 80ml of ethanol and stir at 60°C for 2h to obtain a mixed solution. Then, the graphene oxide solution was added dropwise into the above mixed solution, and the stirring was continued at 60° C. for 12 h. The solvent was evaporated to dryness to obtain a nitrogen-doped graphene precursor. Then, the precursor was placed in a quartz boat, and under the protection of N2 atmosphere, the temperature was raised to 900 °C at a rate of 20 °C / min, and kept for 2 h. 2 After the temperature in the atmosphere is naturally lowered to room temperature, the required nitrogen-doped graphene catalyst is obtained.

Embodiment 3

[0034] Preparation of nitrogen-doped graphene M-NG-900: Weigh 0.1600g of graphite oxide and disperse it in 80ml of ethanol, and ultrasonically treat it for 2 hours to obtain a graphene oxide solution. Weigh 0.0600g FeSO at the same time 4 ·7H 2 O, 0.3500g of melamine was dispersed in 80ml of ethanol, stirred at 60°C for 2h to obtain a mixed solution. Then, the graphene oxide solution was added dropwise into the above mixed solution, and the stirring was continued at 60° C. for 12 h. The solvent was evaporated to dryness to obtain a nitrogen-doped graphene precursor. Then, put the precursor in the quartz boat, under N 2 Under the protection of the atmosphere, the temperature was raised to 900°C at a rate of 20°C / min, and kept for 2 hours. 2 After the temperature in the atmosphere is naturally lowered to room temperature, the required nitrogen-doped graphene catalyst is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com