Preparation of non-noble metal/carbon composites based on metal-organic framework, non-noble metal/carbon composites and their applications

A metal-organic framework, carbon composite material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of reducing the effective utilization of metals, reducing the reaction activity per unit mass of catalysts, etc., achieving low consumption of raw materials, suitable for mass production, The effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

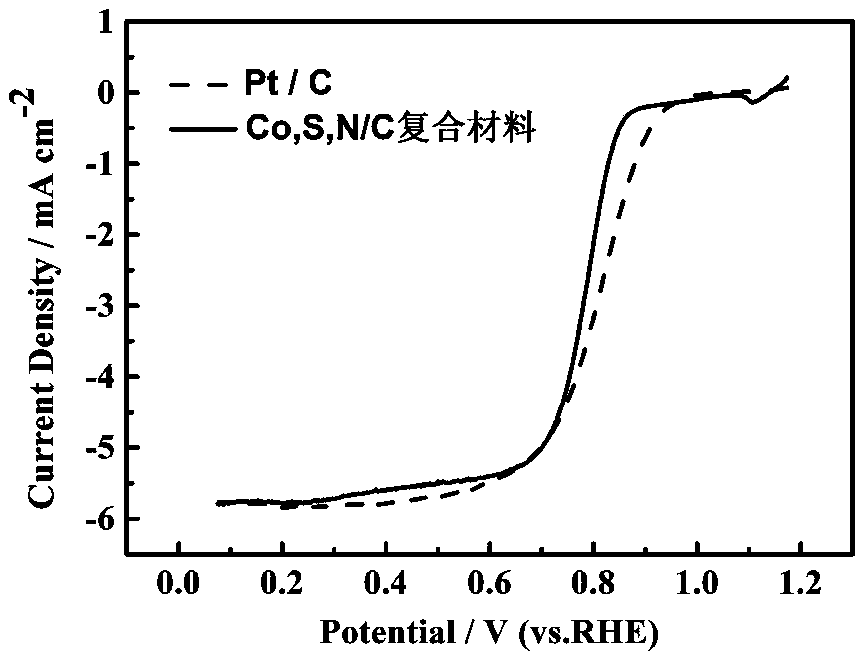

[0040] A kind of non-noble metal / carbon composite material based on the metal-organic framework of zinc / cobalt-benzimidazole (Zn / Co-BZIM), its preparation method comprises the following steps:

[0041] (1) Dissolve 4mmol of zinc nitrate and 1mmol of cobalt nitrate in 100mL of alcoholic solution (methanol:ethanol=1:1), and 20mmol of benzimidazole in 100mL of the same alcoholic solution. Mix the two solutions, stir at room temperature for 2 hours, and let stand at room temperature for 24 hours to obtain a blue-purple complex precipitate, then centrifuge three times at a speed of 8000r / min, wash three times with alcohol solution, and then dry at 60°C for 12 hours to obtain a blue-purple complex. Metal-organic framework complexes of zinc / cobalt-benzimidazole (Zn / Co-BZIM);

[0042] (2) Take 200mg of the above-mentioned Zn / Co-BZIM and put it in a porcelain boat, and take another 20mg of sublimed sulfur in a porcelain boat, put them into a sealed tube furnace respectively, and heat i...

Embodiment 2

[0047] A kind of non-noble metal / carbon composite material based on the metal-organic framework of zinc / cobalt-2-methylimidazole (Zn / Co-BZIF), its preparation method comprises the following steps:

[0048] (1) Dissolve 4.75mmol of zinc nitrate and 0.25mmol of cobalt nitrate in 100mL of methanol, and 20mmol of 2-methylimidazole in 100mL of the same methanol solution. After completely dissolving, mix the two solutions and stir at room temperature 6h, standing at room temperature for 24h, a blue-purple complex precipitate was obtained, centrifuged three times at a speed of 8000r / min, washed three times with methanol solution, and dried at 60°C for 12h to obtain a blue-purple zinc / cobalt-2-formazan Kimidazole (Zn / Co-BZIF) metal-organic framework complexes;

[0049] (2) Get 200mg of the above-mentioned Zn / Co-BZIF and place it in a sealable glass bottle, and put another 40mg of ferrocene in a small open bottle, and put the ferrocene (Fe(C 5 h 5 ) 2 ) was placed in a glass bottle ...

Embodiment 3

[0054] A kind of non-noble metal / carbon composite material based on the metal-organic framework of zinc-2-methylimidazole (ZIF-8), its preparation method comprises the following steps:

[0055] (1) Dissolve 5mmol of zinc nitrate in 100mL of methanol, 20mmol of 2-methylimidazole in 100mL of the same methanol solution, mix the two solutions after complete dissolution, stir at room temperature for 6h, and let stand at room temperature for 24h, The white complex precipitate was obtained, centrifuged three times at a speed of 8000r / min, washed three times with methanol solution, and dried at 60°C for 12 hours to obtain a white zinc-2-methylimidazole (ZIF-8) metal-organic framework complex thing;

[0056] (2) Get 200mg of the above-mentioned ZIF-8 and place it in a sealable glass bottle, and get another 40mg of ferrocene in a small open bottle, which will contain ferrocene (Fe(C 5 h 5 ) 2 ) was placed in a glass bottle with ZIF-8, sealed, placed in an oven, heated to 105°C, and k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com