Nitrogen-doped graphene catalyst and preparation method and application thereof

A nitrogen-doped graphene and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as difficult industrial production, high equipment requirements, and complex synthesis processes, and achieve The effect of easy process, high activity and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

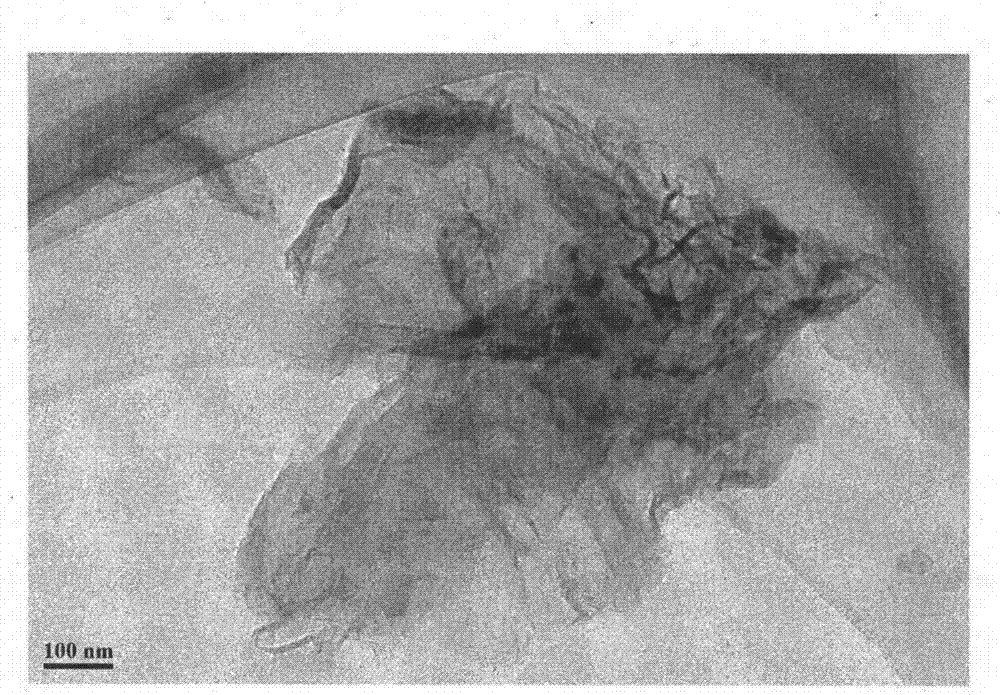

[0030] A nitrogen-doped graphene is made by roasting a nitrogen-doped graphene precursor, and the nitrogen-doped graphene precursor is prepared from raw materials including graphite oxide, cyanamide, and ferrous sulfate heptahydrate. The mass percent of graphite oxide in the raw material is 28wt%, the mass percent of cyanamide is 63wt%, and the mass percent of ferrous sulfate heptahydrate is 9wt%. (The above-mentioned mass percent is based on the total mass of the nitrogen-doped graphene precursor)

[0031] The preparation method of described nitrogen-doped graphene is: weigh 0.0600g FeSO 4 ·7H 2 O, 0.3500g of cyanamide and 0.1600g of graphite oxide were placed in an agate mortar, 20ml of analytically pure methanol was added, and fully ground until the methanol was completely volatilized. Put the agate mortar and the mixture into a vacuum oven at 60° C. for 1 h in vacuum to obtain a nitrogen-doped graphene precursor. Then, put the precursor in the quartz boat, under N 2 Un...

Embodiment 2

[0033] A nitrogen-doped graphene is made by roasting a nitrogen-doped graphene precursor, and the nitrogen-doped graphene precursor is prepared from raw materials including graphite oxide, dicyandiamide, and ferrous sulfate heptahydrate. The mass percent of graphite oxide in the raw material is 28wt%, the mass percent of dicyandiamide is 63wt%, and the mass percent of ferrous sulfate heptahydrate is 9wt%. (The above-mentioned mass percent is based on the total mass of the nitrogen-doped graphene precursor)

[0034] The preparation method of described nitrogen-doped graphene is: weigh 0.0600g FeSO 4 ·7H 2 O, 0.3500g dicyandiamide and 0.1600g graphite oxide were placed in an agate mortar. Add 20ml of methanol of analytical grade and grind thoroughly until the methanol is completely volatilized. Put the agate mortar and the mixture into a vacuum oven at 60° C. for 1 h in vacuum to obtain a nitrogen-doped graphene precursor. Then, put the precursor in the quartz boat, under N ...

Embodiment 3

[0036] A kind of nitrogen-doped graphene, made by roasting nitrogen-doped graphene precursor, described nitrogen-doped graphene precursor adopts the raw material preparation that comprises graphite oxide, melamine, ferrous sulfate heptahydrate, and described raw material The mass percent of graphite oxide in the medium is 28wt%, the mass percent of melamine is 63wt%, and the mass percent of ferrous sulfate heptahydrate is 9wt%. (The above-mentioned mass percent is based on the total mass of the nitrogen-doped graphene precursor)

[0037] The preparation method of described nitrogen-doped graphene is: weigh 0.0600g FeSO 4 ·7H 2 O, 0.3500g melamine and 0.1600g graphite oxide were placed in an agate mortar. Add 20ml of methanol of analytical grade and grind thoroughly until the methanol is completely volatilized. Put the agate mortar and the mixture into a vacuum oven at 60° C. for 1 h in vacuum to obtain a nitrogen-doped graphene precursor. Then, put the precursor in the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com