Process for producing ruthenium base catalyst for producing cyclohexene with benzene selective hydrogenation

A technology for selective hydrogenation and ruthenium catalyst is applied in the field of novel preparation of ruthenium-based catalysts, and can solve the problems of large usage amount, large ruthenium powder catalyst particles and high catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

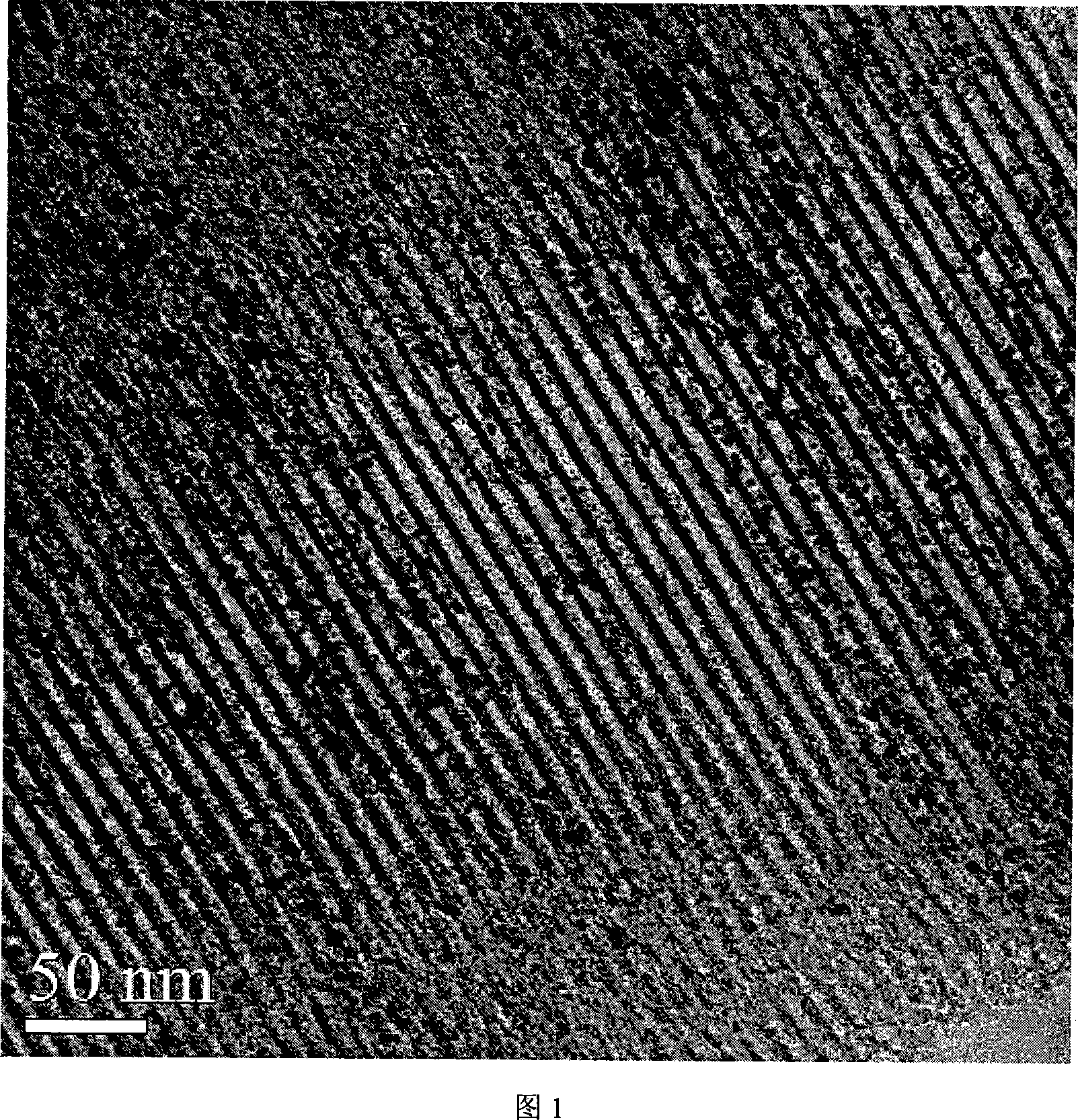

Image

Examples

Embodiment 1

[0016] Example 1: Preparation of Ru / HMS catalyst

[0017] The preparation of the catalyst adopts the preparation method of a cyclohexane / water mixed solvent system. Disperse 1g HMS into 30mL cyclohexane solution, add RuCl dropwise to the above suspension under stirring 3 Aqueous solution (containing Ru 0.01g, 0.04g, 0.08g, 0.12g, 0.16g), after dripping, continue to stir for 10min, filter and dry. The reduction treatment of the catalyst is carried out in a tube furnace. Put the dried catalyst into the tube furnace and pass H 2 / Ar reduction, the gas flow rate is 50mL / min, the reduction temperature is 200-500℃, and the reduction time is 240min.

[0018] The preparation methods of MCM-41 and SBA-15 supported catalysts are similar to those of HMS supported catalysts, which are denoted as Ru / MCM-41 and Ru / SBA-15, respectively.

Embodiment 2

[0019] Example 2: Preparation of Ru-Fe / SBA-15 catalyst

[0020] The preparation of the catalyst adopts the preparation method of a cyclohexane / water mixed solvent system. Will RuCl 3 (Containing Ru 0.12g) and FeCl 3 (The atomic ratio of Fe to Ru is 1:10, 2:10, and 3:10 respectively) mixed aqueous solution was added dropwise to the suspension of 1g SBA-15 and 30mL cyclohexane to prepare the precursor of the catalyst, The reduction treatment conditions were the same as in Example 1.

[0021] The Sn and Ba modified catalysts were prepared by the same method as above. The tin salt and barium salt are respectively pre-dissolved in the mixed solution. The atomic ratios of Sn and Ru are 1:10, 2:10, and 3:10, respectively, and the atomic ratios of Ba and Ru are 1:10, 2:10, and 3:10, 5:10, 10:10, and the catalysts are denoted as Ru-Sn / SBA-15 and Ru-Ba / SBA-15, respectively.

Embodiment 3

[0022] Example 3: Preparation of Ru-Ba / MCM-41 catalyst

[0023] The preparation of the catalyst adopts the preparation method of a cyclohexane / water mixed solvent system. Will RuCl 3 (Containing Ru 0.04g) and Ba(NO3) 2 (The atomic ratio of Ba to Ru is 1:10, 2:10, and 3:10 respectively) mixed aqueous solution was added dropwise to the suspension of 1g MCM-41 and 30mL cyclohexane to prepare the precursor of the catalyst, The reduction treatment conditions were the same as in Example 1.

[0024] The HMS-supported catalyst adopts the same preparation method as described above, wherein the content of Ru in the catalyst is 0.08 g, and the catalyst is denoted as Ru-Ba / HMS.

[0025] Benzene selective hydrogenation activity evaluation example 1: Ru / HMS catalyst

[0026] The amount of catalyst is 1 unit, benzene 50 mL, water 100 mL, reaction temperature 150°C, hydrogen pressure 4.0 MPa, stirring rate 1000 rpm, and the results of selective hydrogenation are shown in Table 1.

[0027] Benzene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com