Novel mesoporous Fe2O3-SnO2-ZSM-5 solid acid prepared by impregnation method, and application study for catalyzing degradation of organic pollutants

A solid acid, H2O2 technology, applied in molecular sieve catalyst, catalyst activation/preparation, oxidized water/sewage treatment and other directions, can solve the problems of increasing COD and chromaticity of wastewater, secondary pollution, difficult continuous production, etc., to simplify the process, Cost saving, good response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

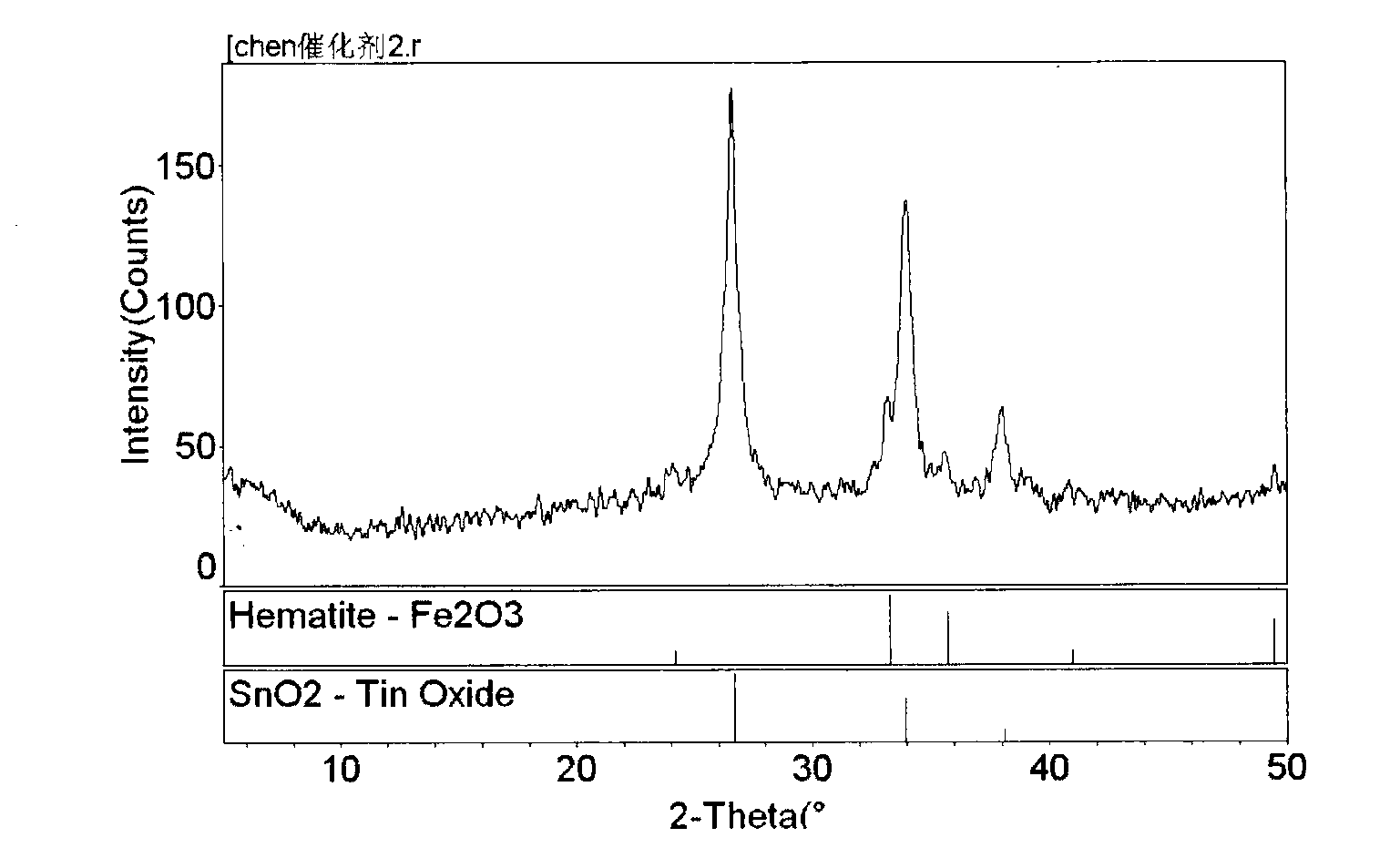

Embodiment 1

[0021] According to a certain proportion, the SnCl 4 .5H 2 Stir and mix O aqueous solution and dried molecular sieve, wherein the amount of molecular sieve is 2%-8% of the total mass, according to n(Sn):n(Fe)=4:1, add a certain amount of Fe 2 (SO 4 ) 3 , adjust pH=6 with concentrated ammonia water to form Sn(OH) 4 and Fe(OH) 3 precipitation. The product is immersed and aged in a water bath at 70°C for 12 hours, and then added with 0.1-0.75mol / L (NH 4 ) 2 CO 3 After washing with aqueous solution, centrifugal sedimentation, drying at 90°C, grinding and sieving with 80 meshes, the mixed oxide precursor was obtained. The precursor is impregnated with 0.25-3mol / L sulfuric acid, filtered, dried at 60-120°C, and roasted at 200-500°C for 3 hours to obtain a tin-iron-silicon solid acid with sulfate as a promoter (hereinafter referred to as SFZ1) .

Embodiment 2

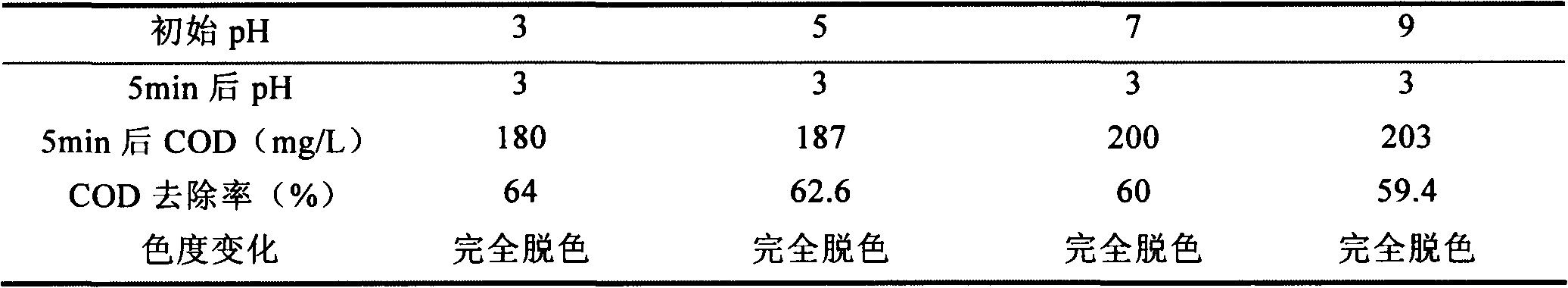

[0023] Take 50mL of emerald blue dye wastewater with an initial COD concentration of 500mg / L, adjust the pH value to 3, 5, 7, and 9 with hydrochloric acid and sodium hydroxide in turn, and add 30% H 2 o 2 1mL / L and catalyst SFZ10.35g / L, stirring, sampling, detection of COD, pH value and chromaticity of the treated wastewater, see Table 1.

[0024] The influence of table 1 different initial pH on reaction effect

[0025]

Embodiment 3

[0027] Take 25mL of Cuilan actual wastewater, the initial COD concentration is 20000mg / L, without adjusting the pH, use SFZ1 to study the degradation effect of high-concentration pollutants, the results are shown in Table 2

[0028] The impact of table 2 SFZ1 adding amount on reaction effect

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com