Dyeing technique of coloring wood-pulp paper used for non-woven material

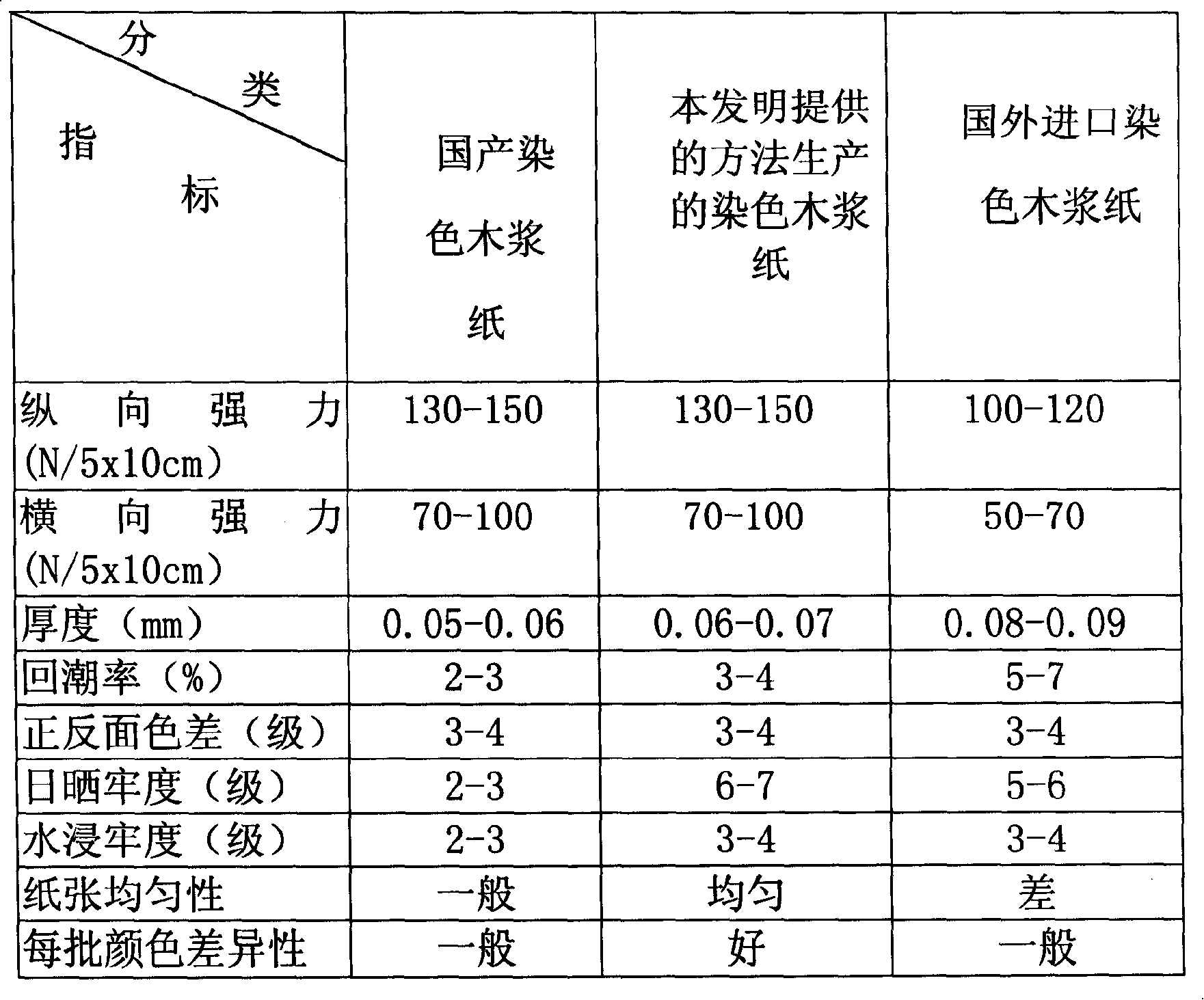

A non-woven material, wood pulp paper technology, applied in the dyeing technology field of dyed wood pulp paper, can solve the problems of color spots on the surface, unsatisfactory, complicated process, etc., and achieves high color fastness, low cost, and uniform coloring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a. Select wood pulp cardboard containing more than 60% redwood;

[0025] b. Put the wood pulp cardboard into the mixing tank to fully break up, so that the wood pulp fibers are evenly dispersed:

[0026] c. Slowly add the dyeing material whose index number is GDFN blue, the weight percentage is 0.6% to 1%, dyeing for 10 minutes; then add the uniformly mixed color fixing agent index number TF232, the weight percentage is 0.8% to 2%, fix the color 10 minutes;

[0027] d. Enter the wire section, press section and drying section, and finally process it into blue wood pulp paper.

Embodiment 2

[0029] a. Select wood pulp cardboard containing more than 60% redwood;

[0030] b. Put the wood pulp cardboard into the mixing tank to fully break up, so that the wood pulp fibers are evenly dispersed:

[0031] c. Slowly add the mixed dyeing matter whose index number is GDFN blue and 3GSFN yellow, the weight percentage is respectively 0.8% to 1.2% and 0.08% to 0.14%, dyeing for 10 minutes; then add the uniformly mixed color fixing agent index number TF232, The weight percentage is 0.8% to 2%, and the color is fixed for 10 minutes;

[0032] d. Enter the wire section, press section and drying section, and finally process it into blue-green wood pulp paper.

Embodiment 3

[0034] a. Select wood pulp cardboard containing more than 60% redwood;

[0035] b. Put the wood pulp cardboard into the mixing tank to fully break up, so that the wood pulp fibers are evenly dispersed:

[0036] c. Slowly add the dyeing material whose index number is DF Cuilan, the weight percentage is 0.2% to 0.4%, and dye for 10 minutes; color for 10 minutes;

[0037] d. Enter the wire section, press section and drying section, and finally process it into light blue wood pulp paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com