Turquoise blue dyeing process of cellulose fiber

A cellulose fiber and process technology, which is applied in the field of dyeing cellulose fibers with reactive dyes, can solve the problems of increasing color pattern, color point, color stain, poor solubility and permeability of dyes, etc., so as to reduce the color pattern and avoid The effect of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The fabric to be dyed used in this embodiment is rayon 250kg, and the dyeing equipment used is a normal temperature and pressure overflow dyeing machine; the dyeing bath ratio is 1:8;

[0040] Specific steps are as follows:

[0041] (1) Pretreatment: Add the fabric to be dyed into a water bath, then add scouring agent SL-101 (concentration: 2g / L), raise the temperature to 90°C and keep it warm for 30 minutes, let off the foot water after cooling down, and wait for dyeing.

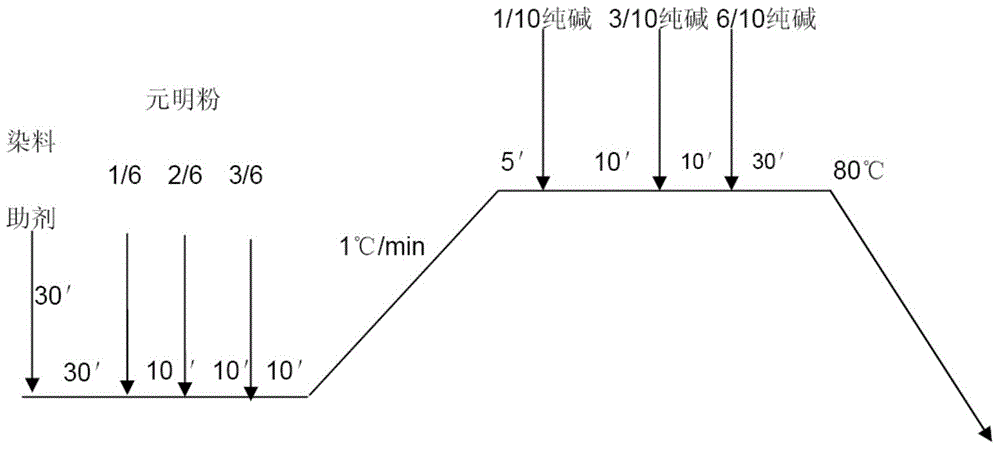

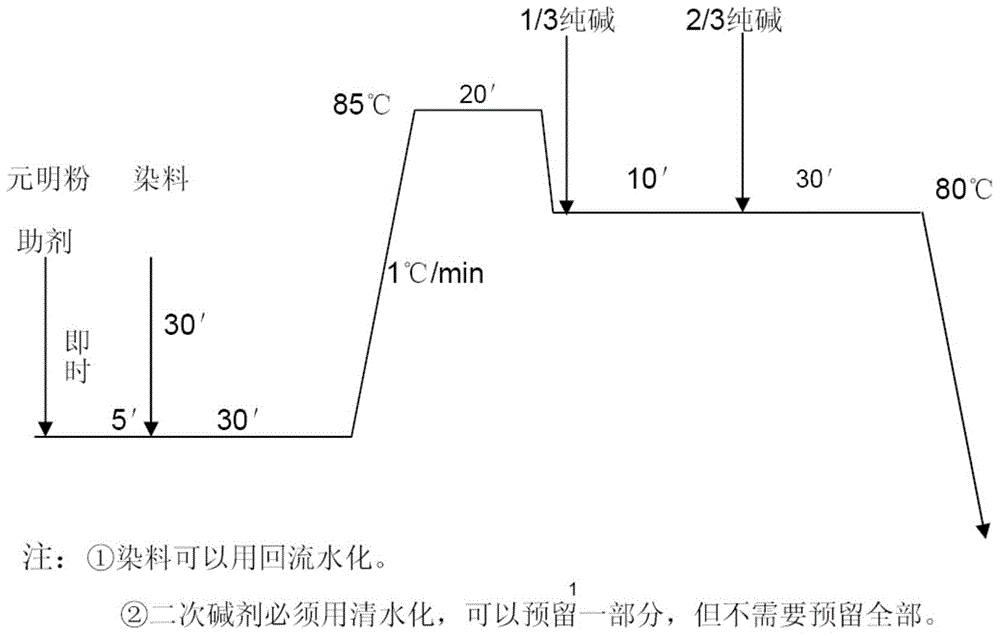

[0042] (2) Dyeing with 21# emerald blue as the main color and 198# bright blue as the auxiliary color, the process is as follows:

[0043] (2.1) Adding sodium sulfate and additives: inject all the sodium sulfate (final concentration in the dye solution: 60g / L) used in this vat into the dyeing vat at room temperature, and the feeding speed is based on not blocking the material pump , and then quickly inject the turquoise blue leveling agent SL-202 (final concentration in the dye solution is 10g / L) in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com