Process for dyeing dark green industrial paperboard

A dark green, industrial technology, applied in papermaking, organic dyes, textiles and papermaking, etc., can solve the problems of poor color uniformity of cardboard, easy fading over time, poor surface oxidation resistance, etc., to achieve high retention rate, clear wastewater, Penetrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

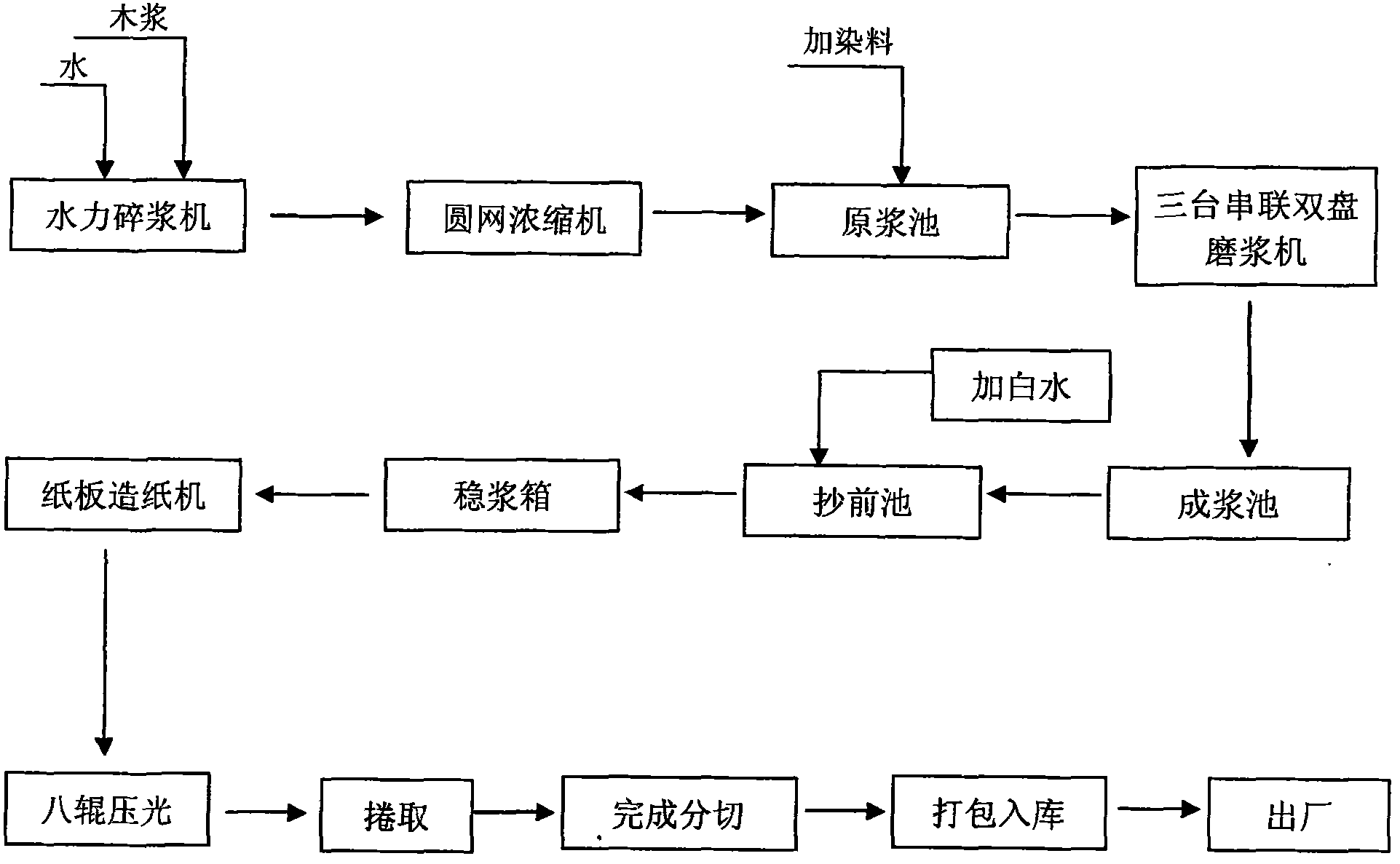

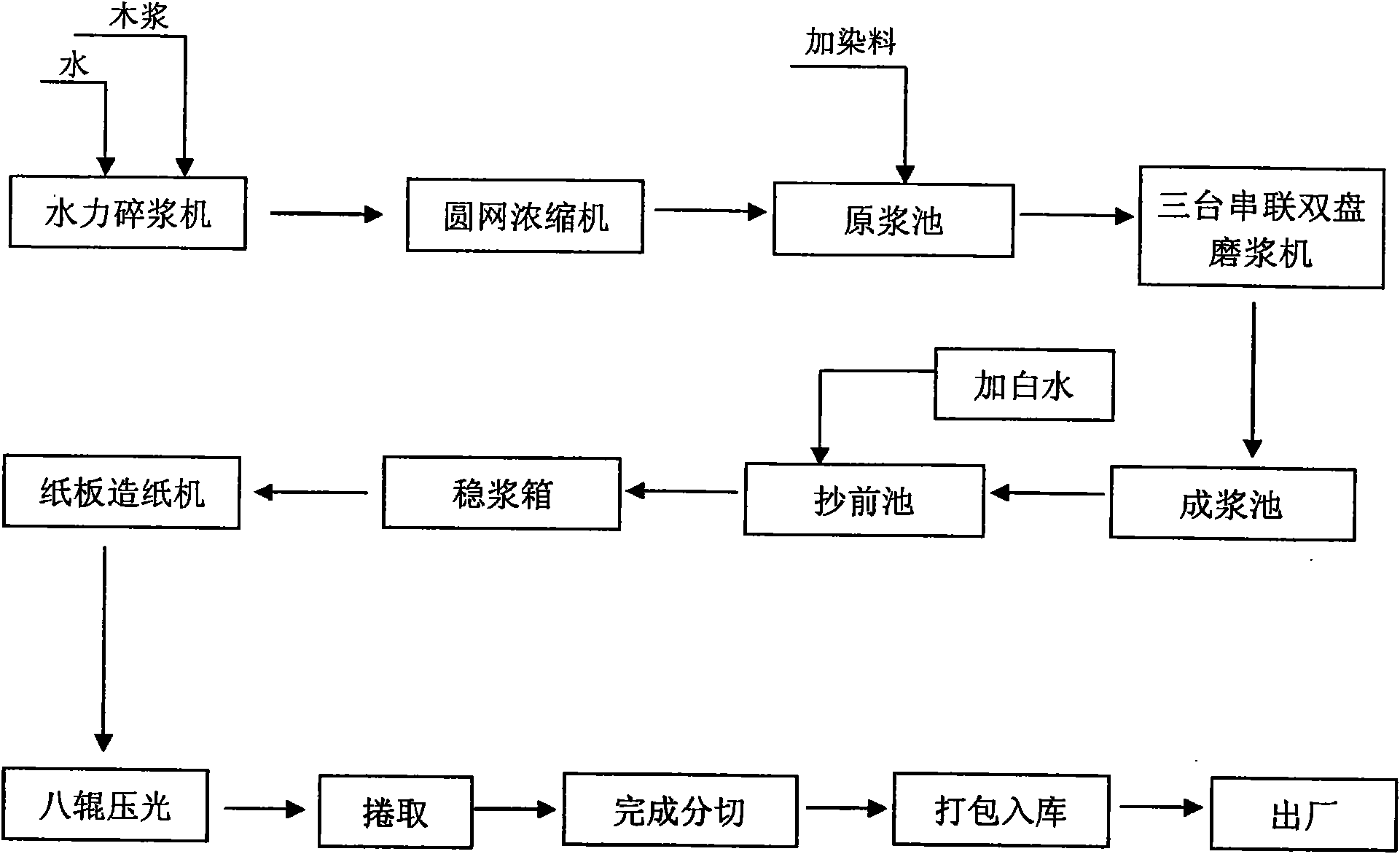

[0013] Its product realization process is as follows: figure 1 As shown, first add water to the raw material pulp until it is crushed by a hydropulper, then dehydrate it to the raw pulp tank through a rotary screen thickener, add the adjusted dye to the raw pulp tank, stir with the pulp for a period of time, and mix evenly. Then use a pulp pump to send it to three tandem double-disk refiners for refining, and the ground pulp enters the pulp tank for use in the paper machine in the next process.

[0014] The raw material formula of this process is (total weight 1000kg):

[0015] a, raw material: get 730kg100% uncolored wood pulp cellulose.

[0016] b. Dye dosage: 7±0.32‰.

[0017] Wherein: direct emerald blue: embodiment 1 gets 60kg, and example 2 gets 66kg;

[0018] Basic bright yellow: get 6.8kg in embodiment 1, get 7.2kg in example 2;

[0019] c, color fixing agent: aluminum sulfate: embodiment 1, example 2 take the surplus of total amount 1000kg respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com