Formula and method for preparing artificial turquoise through 3D printing

A 3D printing, turquoise technology, applied in the field of 3D printing technology and craftsmanship, can solve the problems of increasing the difficulty of turquoise carving, waste of high-priced and effective resources, etc., and achieve the effect of reducing difficulty and cost, simple formula and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

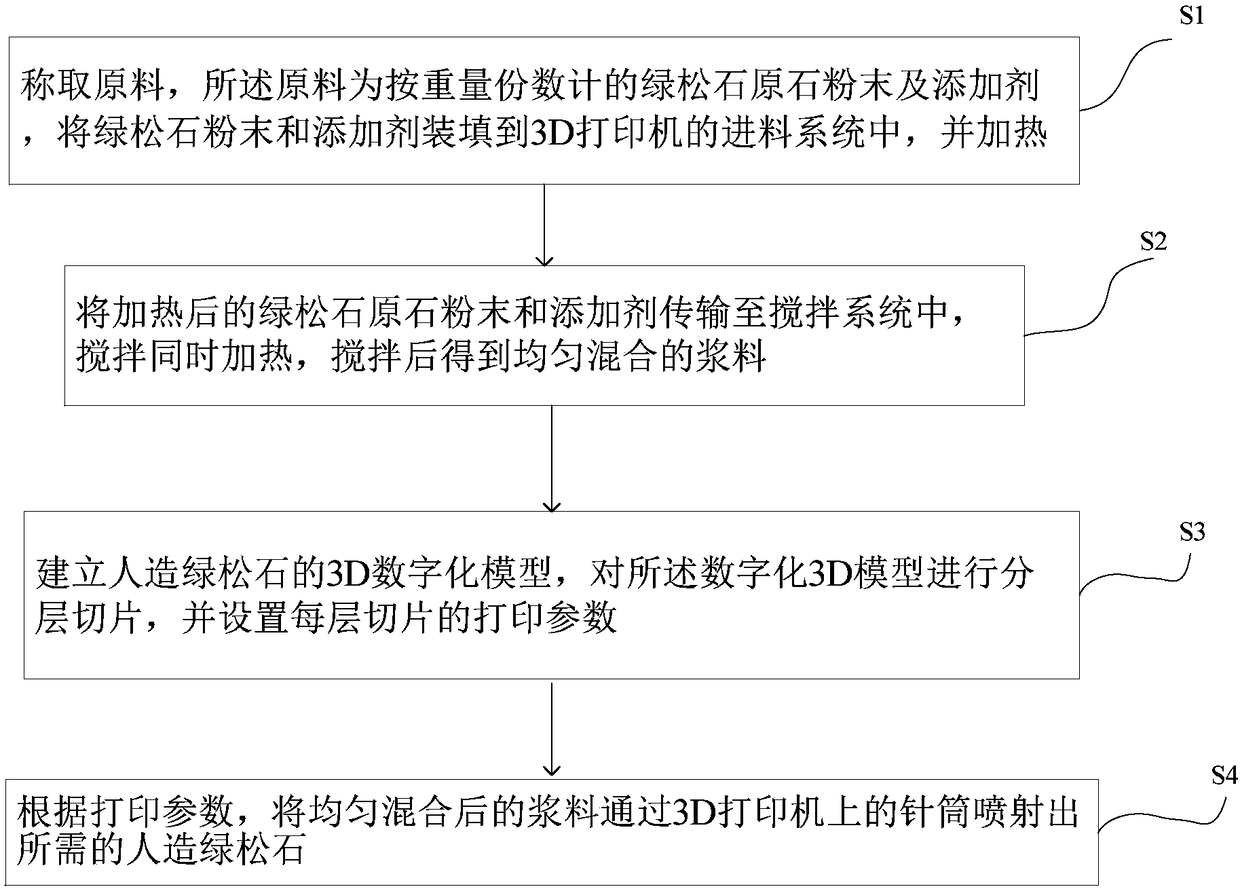

Method used

Image

Examples

Embodiment 1

[0016] The embodiment of the present invention provides a formula for preparing artificial turquoise by 3D printing, including raw turquoise powder and additives in parts by weight, 60-85 parts of the raw turquoise powder, and 15-40 parts of additives; The particle diameter of the turquoise raw stone powder is not greater than 200 meshes; the additive is two or more of paraffin wax, stearic acid, palm wax, liquid wax, mineral oil or vegetable oil. The turquoise raw stone powder is discarded turquoise raw stone powder, the cost is low, and the rare resources are effectively used; the formula is simple; the artificial turquoise printed according to the formula can meet the gemological performance requirements, and the degree of simulation is high; through the digital 3D model , using spray forming to achieve structural control, ensuring that both micro and macro levels can achieve precise control of gemstones, solving the problem of singleness and waste of traditional turquoise c...

Embodiment 2

[0023] The embodiment of the present invention provides a formula for preparing artificial turquoise by 3D printing. The raw material is composed of 70 parts by weight of turquoise raw stone powder and 30 parts of additives; the additive is composed of 92 parts by weight of paraffin wax, Composed of 8 parts of stearic acid. All the other are the same as embodiment one.

Embodiment 3

[0025] The embodiment of the present invention provides a formula for preparing artificial turquoise by 3D printing. The raw material is composed of 75 parts by weight of turquoise raw stone powder and 25 parts of additives; the additive is composed of 85 parts by weight of paraffin wax, Composed of 8 parts of palm wax and 7 parts of stearic acid. All the other are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com