Turquoise blue dye and preparation method and application thereof

A technology of blue dyes and dyes, applied in applications, dyeing methods, azo dyes, etc., can solve the problems of large average particle size, high salt content, low coloring rate, etc., and achieve small average particle size and salt content The effect of low volume and high coloring rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

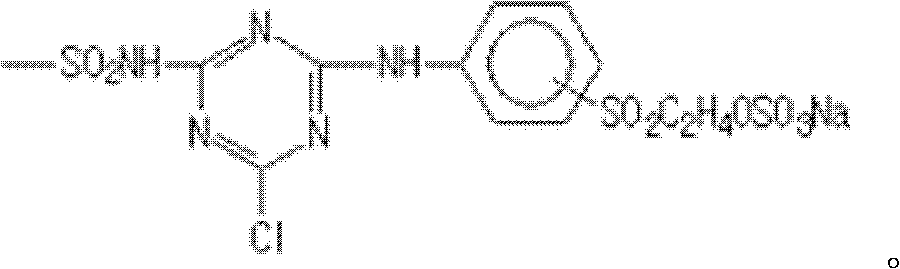

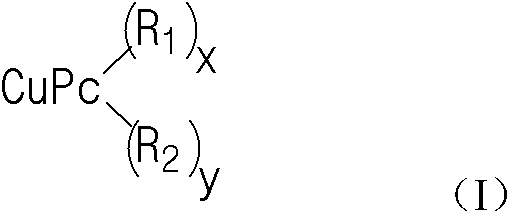

Problems solved by technology

Method used

Image

Examples

Embodiment 1

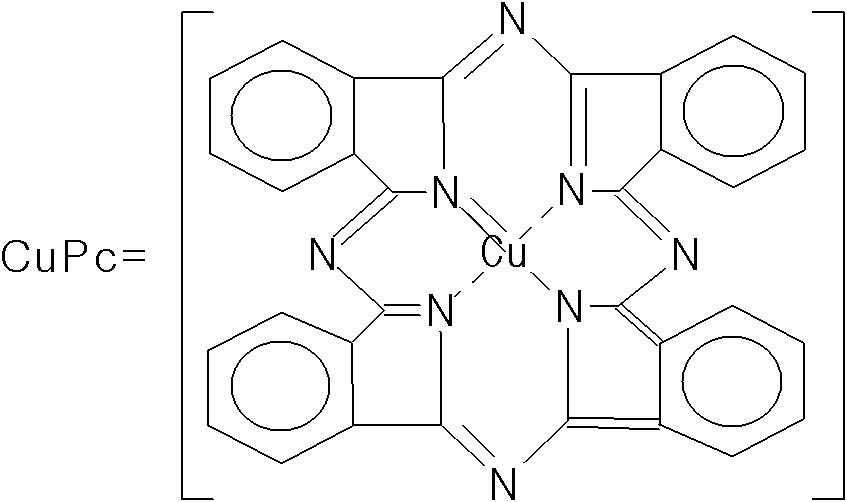

[0063] a. Chlorosulfonation reaction, ice out

[0064] Add 1,750 kg of chlorosulfonic acid to the enamel tank. Circulate cold water to lower the temperature, and control the temperature to 40-50°C. It takes 2 hours to add copper phthalocyanine. Adjust the temperature to 110°C, maintain the temperature at 110-115°C, and react for 4 hours. Adjust the temperature to 55°C, maintain the temperature at 55-60°C, and add 350 kg of thionyl chloride in 2 hours. Maintain the temperature at 55-60°C and react for 3 hours. Adjust the temperature to 90°C, maintain the temperature at 90-95°C, and react for 1 hour. Adjust the temperature to 105°C. Maintain the temperature at 110-115°C and react for 3 hours.

[0065] Adjust the temperature to 10-15°C, add the obtained chlorosulfonation feed liquid into the ice-out tank in a thin stream, and control the temperature. It took 2 hours to maintain the temperature at 0-10°C and stir for 1 hour. Add the deicing liquid into the solid-liquid separ...

Embodiment 2

[0086] a. Chlorosulfonation reaction, ice out

[0087] Add 1,750 kg of chlorosulfonic acid to the enamel tank. Circulate cold water to lower the temperature, and control the temperature to 40-50°C. It took 2 hours to add copper phthalocyanine. Adjust the temperature to 128°C, maintain the temperature at 128-130°C, and react for 4 hours. Adjust the temperature to 65°C, maintain the temperature at 65-70°C, and add 560 kg of thionyl chloride in 2 hours. Maintain the temperature at 65-70°C and react for 2 hours. Adjust the temperature to 90°C, maintain the temperature at 90-95°C, and react for 1 hour. Adjust the temperature to 105°C. Maintain the temperature at 105-110°C and react for 1 hour.

[0088] Adjust the temperature to 20-25°C, add the obtained chlorosulfonation feed liquid into the ice-out tank in a thin stream, and control the temperature. Over 2 hours, the chlorosulfonation feed solution was added. Maintain the temperature at -5~5°C and stir for 1 hour. Add the d...

Embodiment 3

[0111] a. Chlorosulfonation reaction, ice out

[0112] Add 1,750 kg of chlorosulfonic acid to the enamel tank. Circulate cold water to lower the temperature, and control the temperature to 40-50°C. It took 2 hours to add copper phthalocyanine. Adjust the temperature to 128°C, maintain the temperature at 128-130°C, and react for 4 hours. Adjust the temperature to 60°C, maintain the temperature at 60-65°C, and add 525 kg of thionyl chloride in 1.5 hours. Maintain the temperature at 60-65°C and react for 2 hours. Adjust the temperature to 90°C, maintain the temperature at 90-95°C, and react for 1 hour. Adjust the temperature to 100°C. Maintain the temperature at 100-105°C and react for 2 hours.

[0113] Adjust the temperature to 25-30°C, add the obtained chlorosulfonation feed liquid into the ice-out tank in a thin stream, and control the temperature. It took 2 hours to maintain the temperature at 0-5°C and stir for 1 hour. Add the deicing liquid into the solid-liquid separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com