Method for producing compound fertilizer through high-tower granulating, system and compound fertilizer

A compound fertilizer and high-tower granulation technology, which is applied in fertilizer mixtures, fertilization devices, and liquid droplet granulation, etc., can solve the problems of high cost, large steam consumption, large energy consumption, etc. The effect of good quality and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

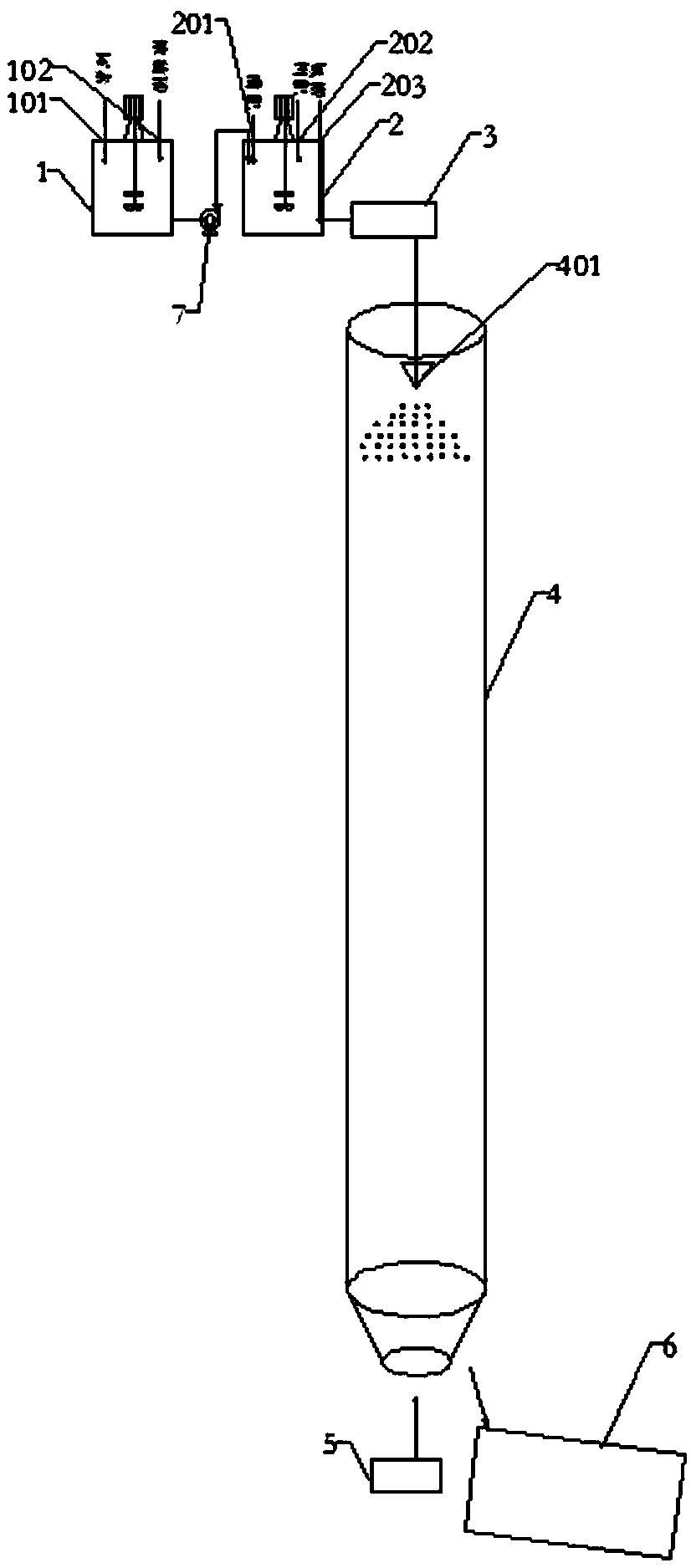

[0103] figure 1 It shows a schematic diagram of the system structure of the high-tower granulation production of compound fertilizer provided by an embodiment of the present invention, as figure 1 Shown, a kind of high-tower granulation system of producing compound fertilizer comprises the urea sulfate reaction tank, NPK slurry mixing tank, emulsifier and high tower connected in sequence;

[0104] A urea feed inlet and a sulfuric acid feed inlet are provided on the urea sulfate reaction tank; a phosphate fertilizer feed inlet and a potassium fertilizer feed inlet are arranged on the NPK slurry mixing tank;

[0105] On the connecting pipeline of the urea sulfuric acid reaction tank and the NPK slurry mixing tank and / or on the NPK slurry mixing tank, an ammonia source inlet is arranged;

[0106] A granulation nozzle is installed in the high tower; the granulation nozzle adopts a rotary centrifugal discharge method to granulate;

[0107] A delivery pump is arranged on the conne...

Embodiment 2

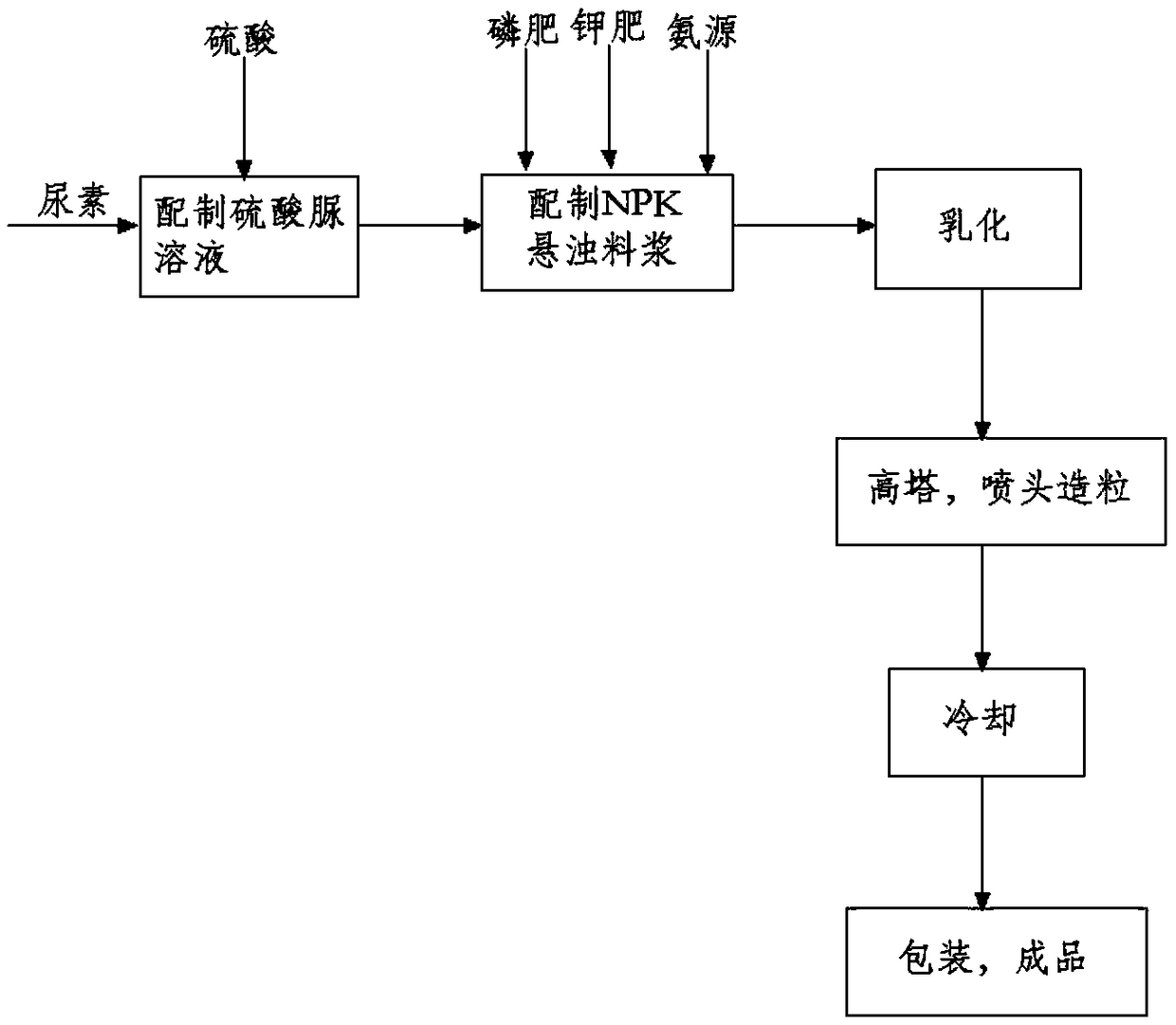

[0110] figure 2 It shows a schematic flow chart of the method for producing compound fertilizer by high tower granulation provided by an embodiment of the present invention; as figure 2 Shown, a kind of high tower granulation produces the method for compound fertilizer, comprises the following steps:

[0111] (a) React sulfuric acid and urea to generate a sulfuric acid urea solution; the molar ratio of sulfuric acid to urea is 1:3.6; the reaction temperature of sulfuric acid and urea is 115°C;

[0112] (b) mixing the urea sulfate solution with synthetic ammonia, monoammonium phosphate and potassium sulfate to form a homogeneous NPK suspension slurry; the mixing temperature is 105° C.; the pH value of the NPK suspension slurry is 5 to 5.5;

[0113] (c) emulsifying the NPK suspension slurry with an emulsifier;

[0114] (d) The emulsified NPK suspension slurry enters the granulation nozzle in the high tower, and the centrifugal force generated by the rotation of the granulati...

Embodiment 3

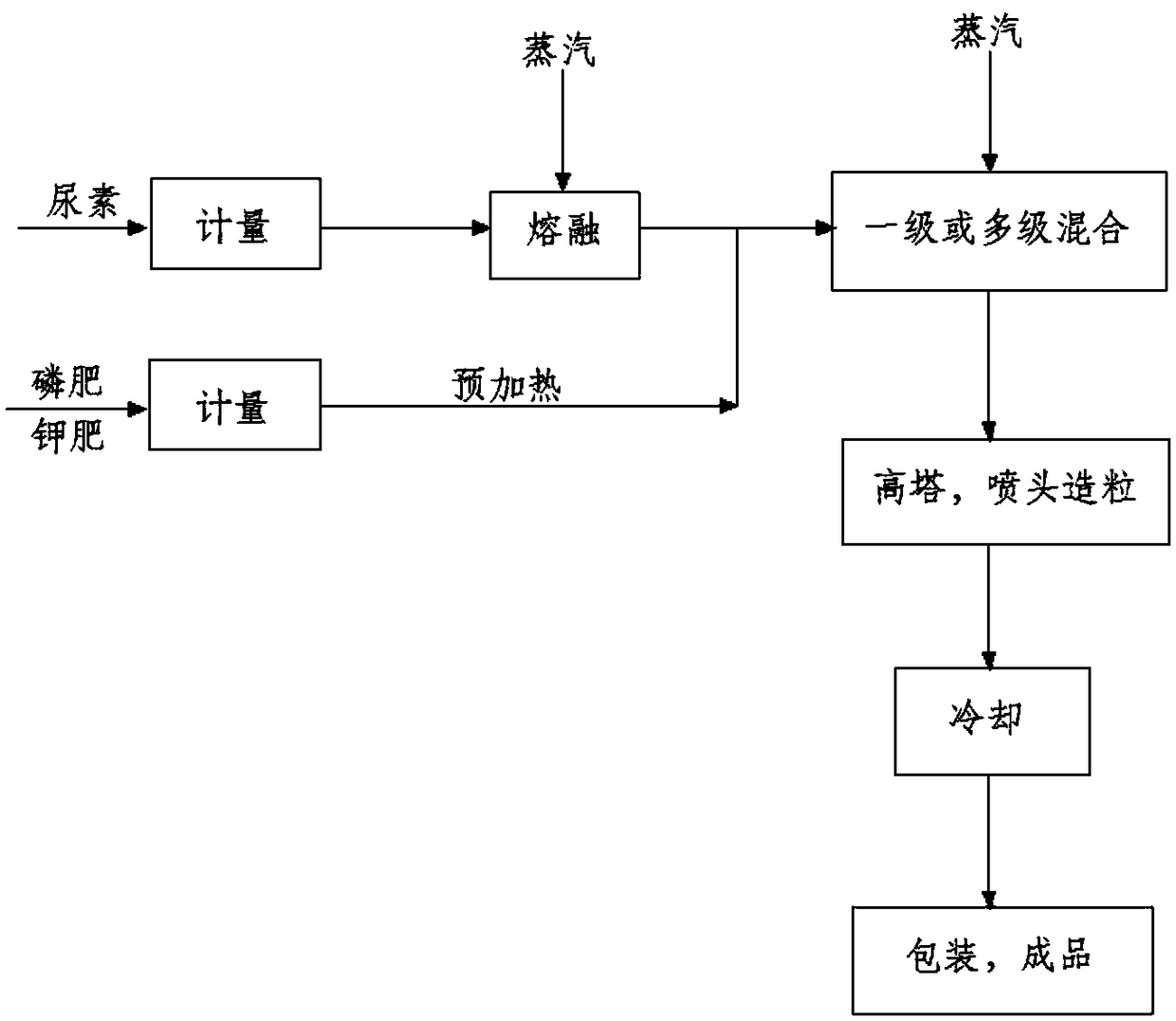

[0117] A method for producing compound fertilizer by high tower granulation, comprising the following steps:

[0118] (a) React sulfuric acid and urea to generate a sulfuric acid urea solution; the molar ratio of sulfuric acid to urea is 1:3.8; the reaction temperature of sulfuric acid and urea is 117°C;

[0119] (b) mixing urea sulfate solution with synthetic ammonia, monoammonium phosphate and potassium sulfate to form a homogeneous NPK suspension slurry; the mixing temperature is 115° C.; the pH value of the NPK suspension slurry is 5.5 to 6.5;

[0120] (c) emulsifying the NPK suspension slurry with an emulsifier;

[0121] (d) The emulsified NPK suspension slurry enters the granulation nozzle in the high tower, and the centrifugal force generated by the rotation of the granulation nozzle will pass the slurry through small holes of 1 to 4 mm to form small droplets of 1 to 4 mm. The free-falling drops and the updraft in the tower realize natural heat exchange, and solidify i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com